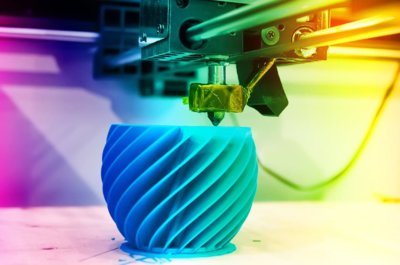

When we discuss the role of 3D printing in the manufacturing world, we often consider the ways in which additive manufacturing could eventually replace traditional techniques. In fact, many developers of AM hardware effectively market their machinery as a direct replacement for things like CNC machines or injection molding systems. But 3D printing can also […]

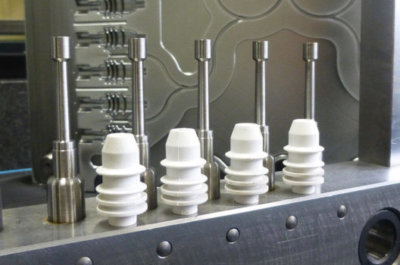

How Does Plastic Injection Molding Work? Typically the Plastic Injection Molding process involves aluminum mold that does not require cooling channels. A professional manufacturer can efficiently produce high-quality parts as per clients’ concerns. In this process, the hot melted resin shot into the mold cavity through the gates and hence converted into molded parts. Once […]

Plastic Injection Mold Making is a specialized process that can produce parts precisely and accurately. This process is highly efficient, simple, and cost-effective. Most of the companies are using this technique to meet their clients’ demand in the market. Plastic injection molding has been known as a dependable, deep-rooted manufacturing procedure for many years. All […]

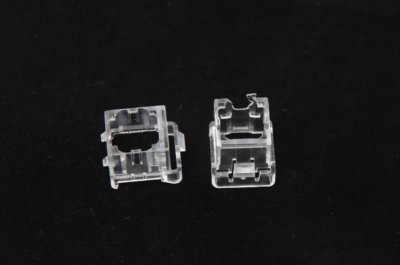

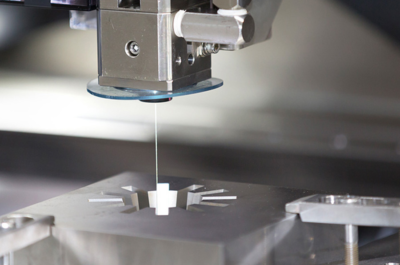

Electrical discharge machining (EDM), sometimes called “spark machining,” is one of the most useful and unique tools in the machinist’s arsenal. Instead of deploying a sharp cutting tool, the process uses sparks to cut through material, opening up new manufacturing possibilities. But it’s not always easy to identify when EDM should be used. In fact, […]

Plastic molding products can be identified everywhere, for instance, jars, protective caps, plastic tubes, grips, accessories, kitchen utensils, and so on. Plastic is typically a synthetically produced non-metallic compound that can be involved in making various sorts of products effectively to meet client’s demands. Looking to hire a plastic mold maker? You can easily find […]

Many products are designed to interact with food in some way or another. Items like containers, packaging, cans and bottles, kitchen utensils, machinery, and appliances can all make direct or indirect contact with edible goods, which are then consumed. It’s important to know what your food is made from, but it’s equally important to know […]

When developing a product, making a physical prototype can help you with research, testing, financing, and much more. And thanks to rapid prototyping service providers like 3ERP, it’s easy to make an affordable prototype in a short timeframe. However, some companies delay prototyping simply because they don’t know where to start; they don’t know which […]

What is Plastic injection molding? In the Plastic injection molding process, usually molten plastic injected into a mold to produce exceptional quality of plastic parts plates, plaques, signs, and product branding elements. After injecting molten plastic, it gets cools and solidifies to yield a wide range of plastic parts from the Plastic Injection Mold. When […]

Prototyping is an important part of the development and commercialization of medical devices. Most medical products have to meet strict safety requirements, so it is important to iterate a variety of prototypes for R&D and testing in order to make a safe and functional end-use part. Different medical prototypes require different materials. The choice between […]

In simple words, injection molding is a manufacturing process that is used to inject molten material. When the molten metal is injected into the mold, the outcome will be your required parts. Plastic Injection Molding is specially intended for the production of plastic parts. Different projects require different sorts of parts and they vary with […]

In certain conditions, even the strongest metal parts can suffer from corrosion, which occurs when metals react with their environment. Corrosion turns the surface of the metal part into a metal oxide, hydroxide, or sulfide. Any metal can suffer from some degree of corrosion, though some react under different circumstances than others. Importantly though, corrosion […]

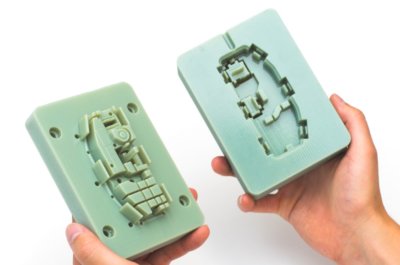

Prototype molding- what it is? When we talk about Prototype Molding, it is specifically intended to produce prototypes rapidly and small to medium series of plastic parts. In a nutshell, we can say this is the most convenient method to produce samples, prototypes, and small series rapidly in an inexpensive way. To get the best […]

Here at 3ERP, we often receive Requests for Quotation (RfQs) where the customer has a passionate vision for a product but lacks the technical skills to create a digital 3D design that is suitable for production. Unfortunately, if the customer cannot submit a usable 3D design — or at least create a technical drawing that […]

With its excellent strength-to-weight ratio and resistance to corrosion, titanium is one of the most useful and popular metals for industrial engineers, architects, and consumer product designers. It is named after the Titans of Ancient Greek mythology, after all, and it usually lives up to its name. Titanium has desirable material properties, and it is […]

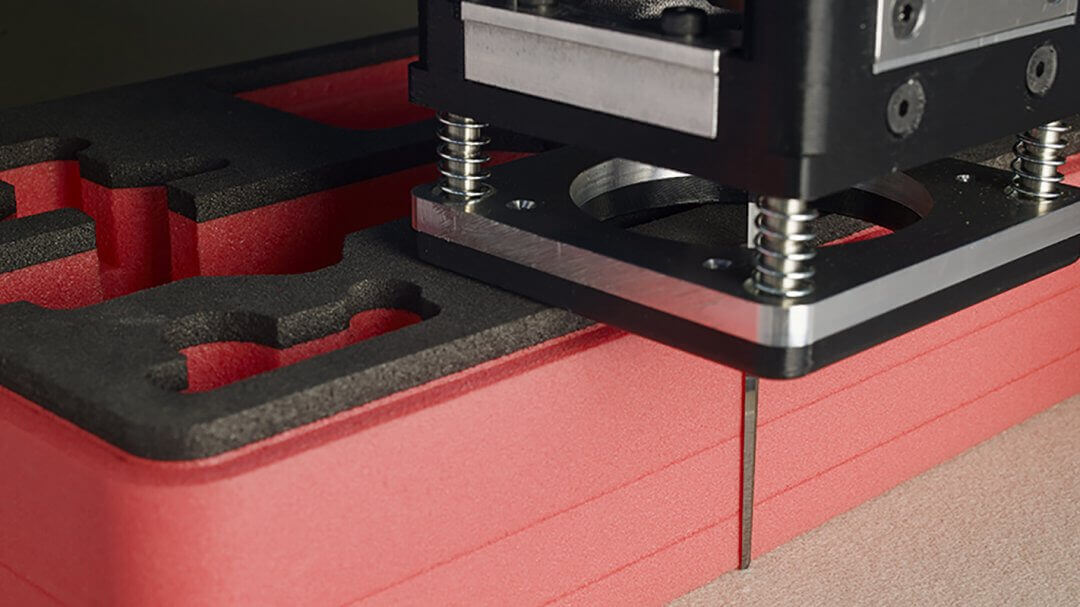

Sheet metal fabrication is a valuable prototyping and production method for making robust functional parts like panels, brackets, and enclosures. However, unlike other manufacturing techniques, sheet metal fabrication actually comprises many different processes, all of which manipulate the sheet metal in different ways. These different processes may involve cutting the sheet metal, shaping it, or […]

Plastic Injection Molding Plastic Injection Molding is a molding process whereby a heat-softened plastic material is injected into a comparatively cool cavity to give an article a required form. It is widely used by many manufacturers to make desired parts from a plastic material. Molten plastic injects into a mold under high pressure to yield […]

After the invention, injection Molding has turned into a multibillion-dollar industry. This process makes it possible to manufacture many durable consumer and industrial items cheaper than everything else. It produces around 32% of plastics by weight. When we talk about the machine of injection molding, it is made up of various components such as the […]

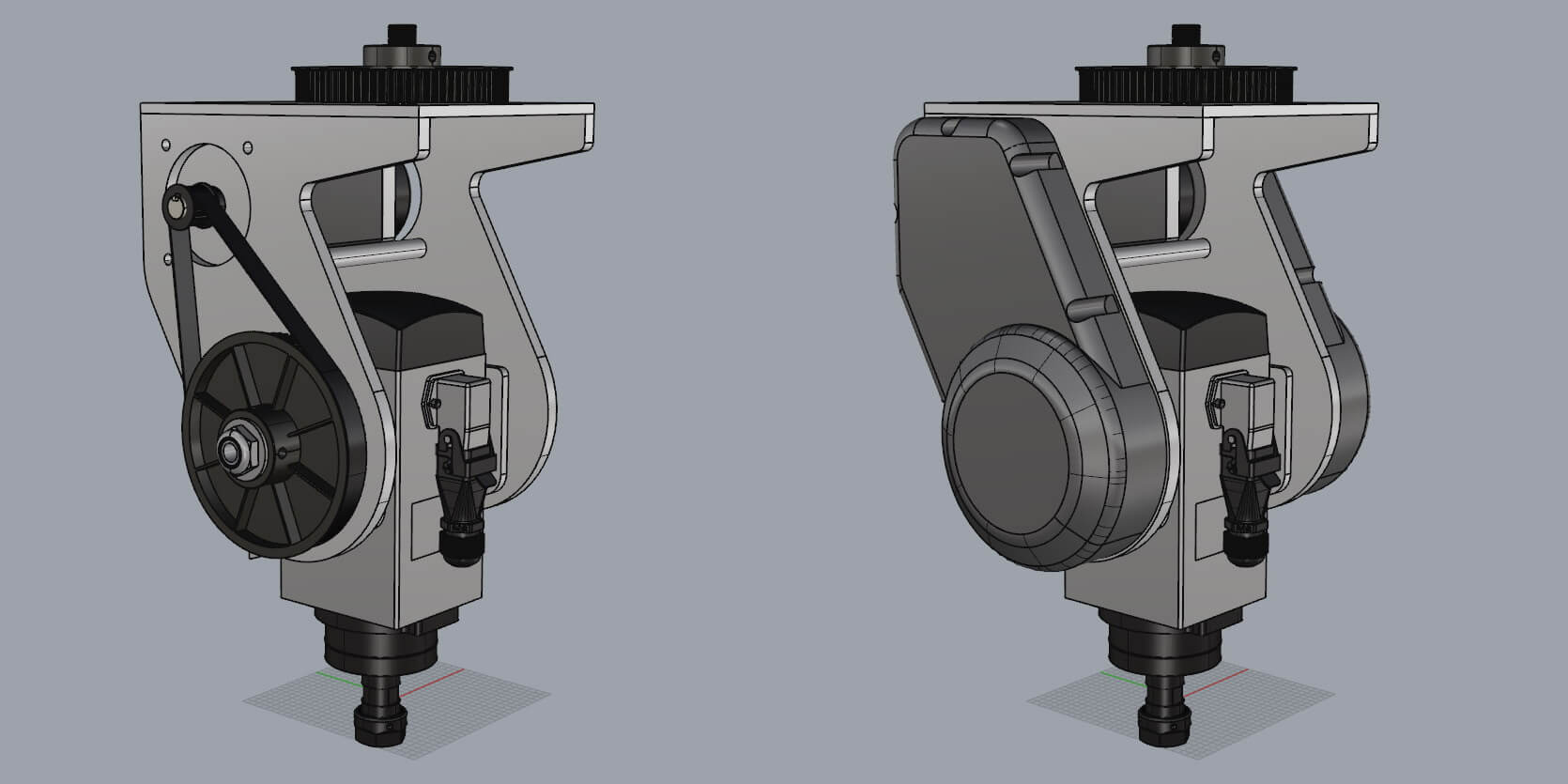

What is Rapid Tooling? Rapid Tooling is an advanced method that involves the practice of Rapid Prototyping techniques and conventional tooling to yield a mold quickly. This technique is specially intended to streamline the mold structure for low cost within a deadline. Most often this is used in the field of rapid injection molding when […]

Urethane casting is a low-cost molding process for the fabrication of rigid or rubber-like plastic parts. Suitable for prototypes and certain end-use parts, urethane casting does not require costly hard tooling, instead using silicone molds to make a limited number of castings. Customers have several options when it comes to urethane casting. In addition to […]

Metal fabrication projects are a delicate process due to a number of factors, but the most daunting is building the actual practical version of the design and bringing it to life. Even if you’re outsourcing to a 3rd party fabrication service provider with a lot of experience, things can go wrong. Getting the most of […]

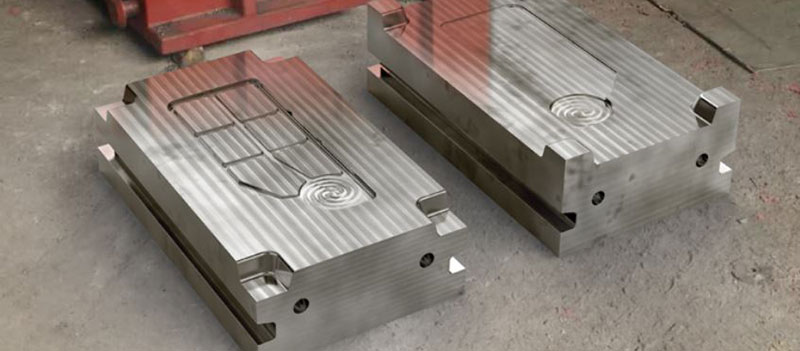

When we talk about mold, it is simply a negative impression that you want to cast as per your requirement. It can capture each detail of an object right down to the slightest indentation. Plastic injection molds are usually made from toughened or pre-hardened steel, aluminum, or copper alloy. When we talk about the most […]

Rapid Tooling System – Industrial Applications- In the process of Rapid Tooling, either Rapid Prototyping (RP) technique can be used to create a mold rapidly or the Rapid Prototyping process can be used to fabricate a tool for a limited volume of prototypes. This process consumes less time and cost than a conventional tool. In […]

The Plastic Injection Molding process involves the injection of molten plastic into a mould cavity, which hardens within the mold to produce the final products as per the requirements. This is one of the most sought after the process of manufacturing parts and products at affordable pricing range. This process is reliable and efficient enough […]

Today’s economy is defined by impulse. The ease of online shopping makes life simple — perhaps too simple — for consumers to order products as soon as they want them. Personalized ads are targeted at these potential consumers to encourage spending, and orders can be completed with just a few clicks. In many countries, packages […]

Molds — negative impressions of parts that can be filled with material — are an integral part of manufacturing. In fact, the majority of the world’s plastic parts are made via injection molding. But while metal injection molds are expensive and can only be made by professionals, flexible silicone molds are highly affordable and can […]

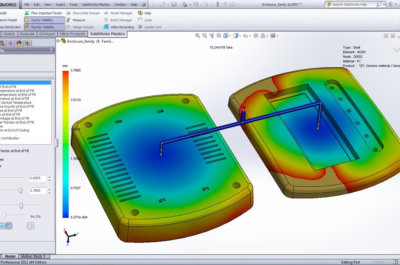

Injection molding simulation software is an important part of the IM workflow, allowing designers to assess the feasibility of their molds and moldings. This article looks at how it works. What is injection molding? Injection molding is a manufacturing process behind a huge number of manmade objects, from water bottles to automotive components. It comprises […]

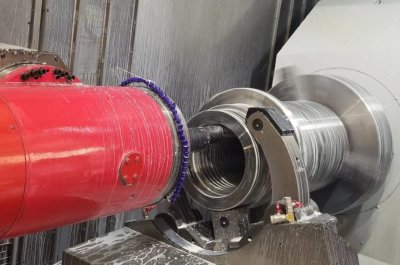

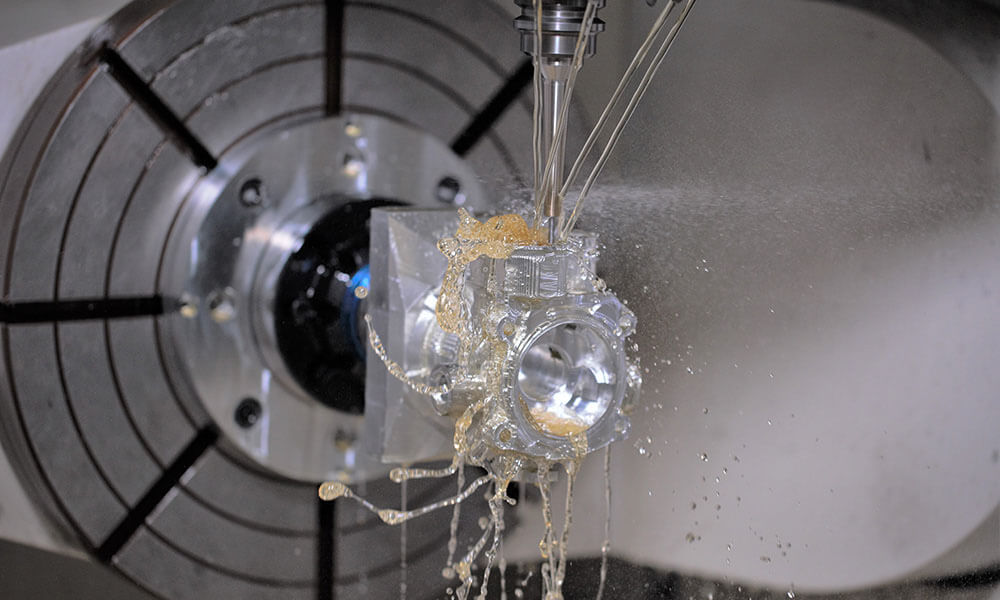

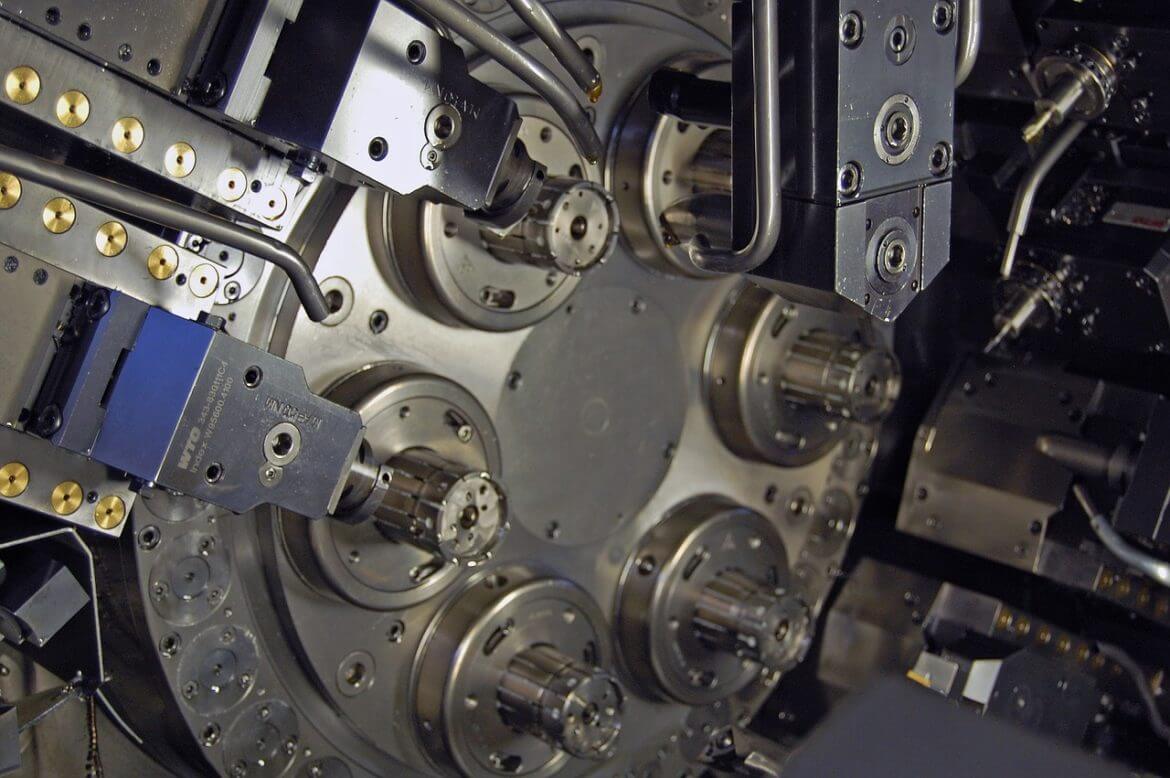

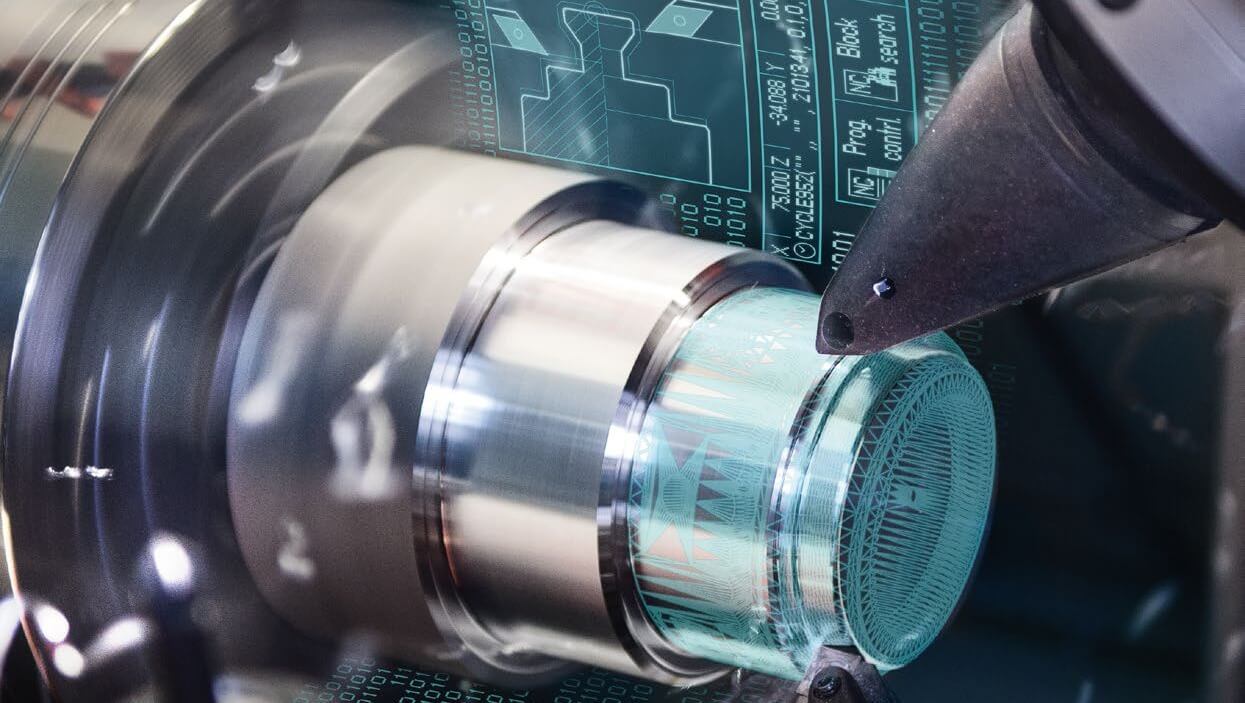

Companies that design and manufacture plastic or metal parts will often require rapid machining services at some point during product development. This article looks at the ins and outs of the manufacturing process and why it is so important. What is rapid machining? Rapid machining is the machining of parts and prototypes with an explicit […]

Injection molding is a manufacturing process that produces strong and durable parts in giant quantities. It is one of the most cost-effective manufacturing processes and works with a wide array of plastic materials, including thermoplastics and thermosets. You can even mold plastic components over other materials using overmolding and insert molding. Sometimes, however, typical injection […]

If there’s a technological device that truly defines our current generation of science and technology, it must be the smartphone. These ever-evolving bars of glass, plastics and electronics have taken on a massive portfolio of functions, offering operations just as diverse as computers (if not more) while providing far more ease of use and portability […]

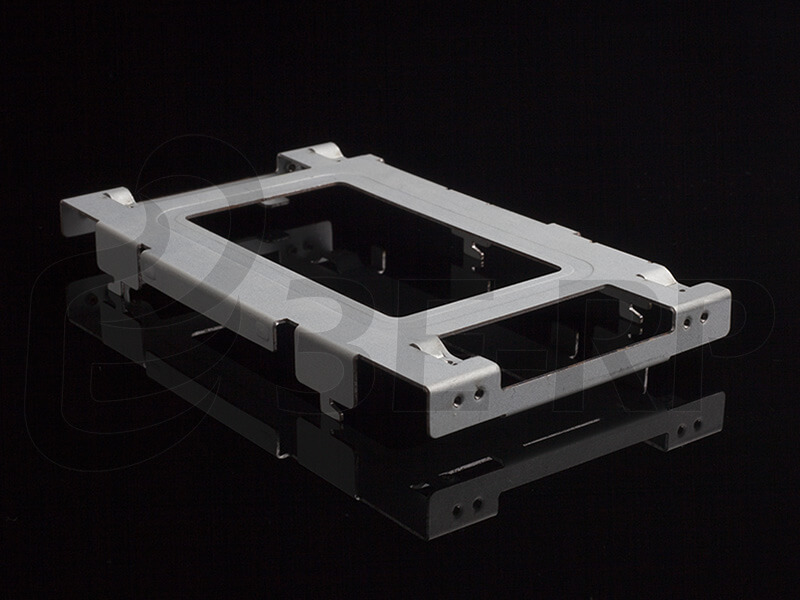

For developers of electronic products, a robust and aesthetically pleasing enclosure can turn a scrapheap-bound piece of junk into a market-conquering phenomenon. Both prototypes and end-use parts require enclosures, which represent the vital finishing touch of an electronic device and which keep the components and wiring in place to ensure durability, function and a professional […]

For product designers and developers, rapid prototyping can play a crucial role in bringing a commodity from concept to finished product. Thanks to new technologies like CNC machining and 3D printing, developers can iterate prototypes in a short time period, trying out new designs and materials. Rapid prototyping is the process of assembling functional or […]

With more than 10 years in the rapid manufacturing business, 3ERP has built up rich experience in CNC machining parts for both prototyping and mass production. In any form of manufacturing, machining tolerances play a crucial role as they define the allowable variation in dimensions and physical properties of a manufactured part. Maintaining tight tolerances […]

Ordering your first batch of prototypes can be a daunting prospect, especially if you are unfamiliar with the company that will build them. But working with a prototyping company needn’t be a difficult experience once you know what to look out for. This article tells you what to expect from companies that build prototypes. It […]

Injection molding is the world’s most popular process for manufacturing plastic parts. Using durable metal molds, injection molding makes it possible to create hundreds of thousands of units in a short space of time. And molding isn’t expensive. At least, injecting a shot of material into a mold isn’t: the process is lightning-fast, and pellets […]

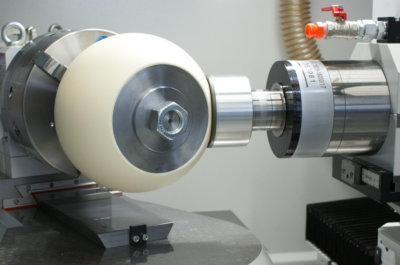

For quality control of CNC machined parts, most machine shops use a Coordinate Measuring Machine. A CMM checks that the geometry and dimensions of a finished part match the original design, ensuring that the customer does not receive defective parts. It identifies even the most marginal errors and allows the machinist to rework a faulty […]

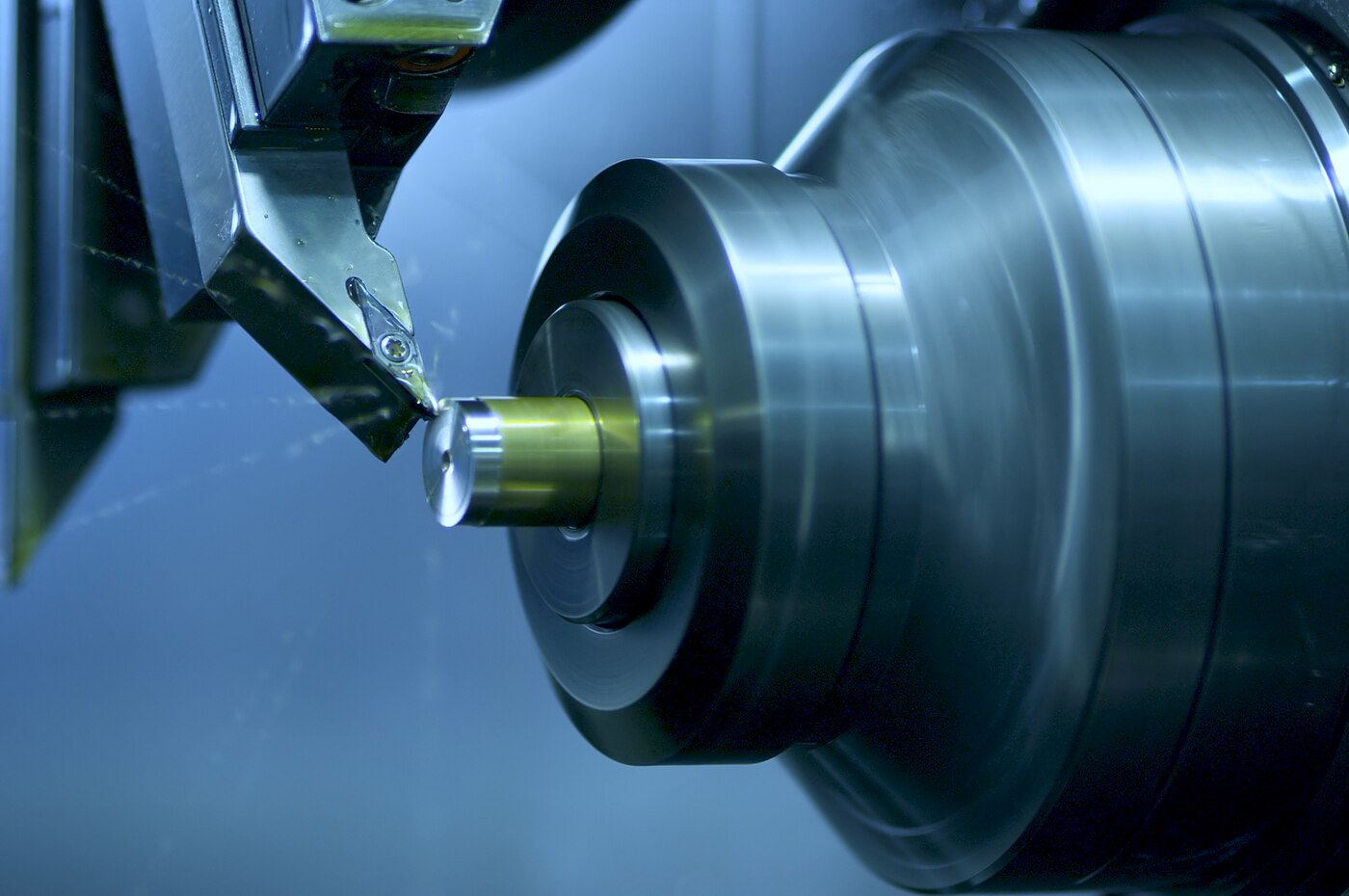

For prototypes and end-use parts, accuracy is a hugely important aspect of metal machining. Accuracy means you’re getting a part that looks and feels exactly like the one you designed, with no errors that can impact mechanical function. Thanks to the rise of computer numerical control and CNC machining, the subtractive manufacturing process of metal […]

With an abundance of manufacturing technologies making the rounds these days, there are so many to choose from. While all of them have their unique niches and those specifics areas where they excel above others, CNC machining is proving to be the most popular industrial option among the pack. Here are just some of the […]

As a major source of manufacturing revenue, the defense and military industries rely on some very flexible, cost-effective and reliable technologies. With global defense spending expected to grow at a CAGR of about 3 percent over the 2019–2023 period, reaching US$2.1 trillion by 2023, they also invest heavily into modern machining solutions in various different sectors of their workflow. […]

When it comes to custom production parts, there are few faster methods than CNC machining. Thanks to the speed of CAD modeling, the ease of online orders and the availability of global shipping, it is now possible to order and receive custom machined parts in a matter of days. It’s no exaggeration to say that […]

Injection molding is the most widely used manufacturing process for plastic parts. So it’s no surprise that there are many plastics available for injection molding, all of which are available in pellet form. Moldable plastics range from highly durable polycarbonate to impact-resistant ABS. This guide looks at 15 of the most popular plastics used for […]

Magnesium is a lightweight metal with high level of machinability that can be CNC machined to create parts with high strength and excellent corrosion resistance. However, magnesium can be difficult to machine due to its tendency to ignite or explode if proper precautions are not taken. It provides a hazard for CNC machinists: the chips […]

Precision manufacturing is one of the biggest advances in manufacturing in recent times. Unlike some of the other trends in the industry, precision manufacturing has the potential to completely revolutionize how a range of industries operate, allowing to cut costs while simultaneously increasing efficiency, tightening tolerances, and providing a more reliable way of producing parts. […]

Metal prototypes are important for businesses in many industries, from aerospace to electronics, because an effective metal prototype can lead to a better finished product. This article discusses the importance of metal prototypes and looks at situations in which metal prototyping is favorable over plastic prototyping. It also discusses various effective methods for creating metal […]

CNC machines, particularly in the realm of large CNC machining, are an impressive tool for fabricating a diverse array of products, but they come with their own unique size constraints. The average machine shop or hobbyist is less likely to possess a significantly large machine, as such equipment can be impractical in many situations. This […]

The ability of 3D printing to easily create figurines, models and plastic electronic casings has been a massive boon to the toys and games industries. Manufacturers and enterprising makers have been employing the technology to make a whole bunch of unique tools for gamers to make the most of their play. Customized Miniatures & Tabletop […]

Today’s companies have more options than ever to manufacture parts from almost any materials. And when it comes to producing parts from plastics, most end up opting for either injection molding and 3D printing. While the 3D printing option is generally more well-known because of its availability to even consumer-level users, the injection molding market […]

Injection molding is the most popular method for manufacturing plastic parts on the planet, so it’s not surprising that the global market for the process was valued at almost 260 million U.S. dollars, with projections for continued growth in the foreseeable future. The technology is used in a wide variety of industries, including aerospace, medical […]

As a material widely used in everyday items from clocks to knives to bricks to pottery, machining ceramics can be a great way to expand a company’s materials portfolio. Though they are traditionally made using a kiln, machining them can be a useful endeavor that gives your machine shop a unique selling point. As a […]

There are two broad categories of injection molding tools: soft tooling and hard tooling. Selecting the appropriate material depends on a variety of factors, such as budget limitations, volume requirements, and material selection. Soft tooling is used for prototyping or small production runs while hard tooling is used for high-volume production. What is Soft Tooling? […]

For mass production of simple parts, there are few manufacturing processes more suitable than injection molding, the most widely used plastic manufacturing process in the world. Injection molding is used to make everything from food packaging to aircraft parts, while its speed and cost-effectiveness — especially at scale — make it the top choice of […]

For most people, the knowledge about manufacturing and prototyping technologies of today consists mostly of what they learn in school or what they stumble upon on the internet. Many are at least vaguely familiar with the process of 3D printing, which can offer sustainable and eco-friendly manufacturing possibilities. But even though 3D printing is becoming […]

With supply chains interrupted and demand for products decreasing, the coronavirus pandemic is hitting the manufacturing industry hard. And because several countries are still months away from controlling their local COVID-19 situation, it could be a while before business gets back to normal. But that doesn’t mean the rapid manufacturing world will sit idly by […]

As we enter a more eco-conscious era of manufacturing, there are tons of concerns that new technologies are possibly taking us backwards. The concerns often levied at 3D printing put its abundant use of plastics and power usage under fire, and sometimes these arguments are valid. However, players within the industry are doing their best […]

The modern manufacturing industry is beginning to lean heavily into new capabilities that allow for specially machined custom parts that suit the precise needs of individual buyers. This sort of service and production style offers clients a means of making the best use of their tools, products or any other machined parts they may need, […]

In the US alone, the sports goods industry makes about $45 billion dollars annually, requiring the creation of all sorts of gear, fashion and accessories. The worldwide estimates can go as high as $300 billion. As with most manufacturing industries, the worlds of games and sports are waking up to the possibilities additive manufacturing has […]

When making CNC machined parts, it is important to first figure out the best way to load and hold the workpiece. This step comes before plotting the tool path, and plays an important role in the process. Workholding and loading are crucial aspects of the CNC machining process. Your workpiece is only going to be […]

What is a machine shop? A machine shop is a place where machining, a type of subtractive manufacturing, takes place. It’s not a “shop” like a store, but rather a room or building containing machinery where machinists and other technical staff make things. The shop can be part of a large factory or a room […]

While 3D printing is largely associated with manufacturing and prototyping, it has garnered some attention for its ability to reconstruct, renovate and repair objects as well. This makes it a fairly useful resource for museums, curators and historians looking to reconstruct objects, artifacts and even fossils with the use of printing, scanning and digital models. […]

The electronics industry is one of the largest and most powerful industries in the world, and many of its products — from professional high-tech equipment to consumer electronics — are made with CNC machined parts. Machined components for the electronics industry include both plastic and metal parts, and technologies used to produce them include CNC […]

If you live in a house or apartment in a developed country, chances are your building was built from bricks and mortar — the traditional way, with traditional materials. But if you’ve read much about 3D printing, you’ve probably read a few stories about 3D printed buildings: additive architectural phenomena that forgo bricks and mortar […]

When it comes to CNC milling and turning machines, there are a lot of details that make a significant difference in your workflow. No single machine can handle every possible manufacturing operation so it’s wise to note the characteristics that would be most suitable to one’s operations. There are many such calculations to keep in […]

For precision CNC milling services, the right tools are required. Basically, in order to perform precision machining jobs, you need CNC milling machines. These machines are precise, accurate and fast. We suggest that to providers that offer these services, you outsource the job if you deal in the products of parts. You can use the […]

Mills, lathes and all sorts of CNC machines are marvelous machines, but they all require diligent care to keep them working under optimal conditions. Maintenance can be a hassle but it is necessary for any machine shop or even hobbyist to regularly undertake to avoid breakdown or operational inefficiencies. As such, this article will serve […]

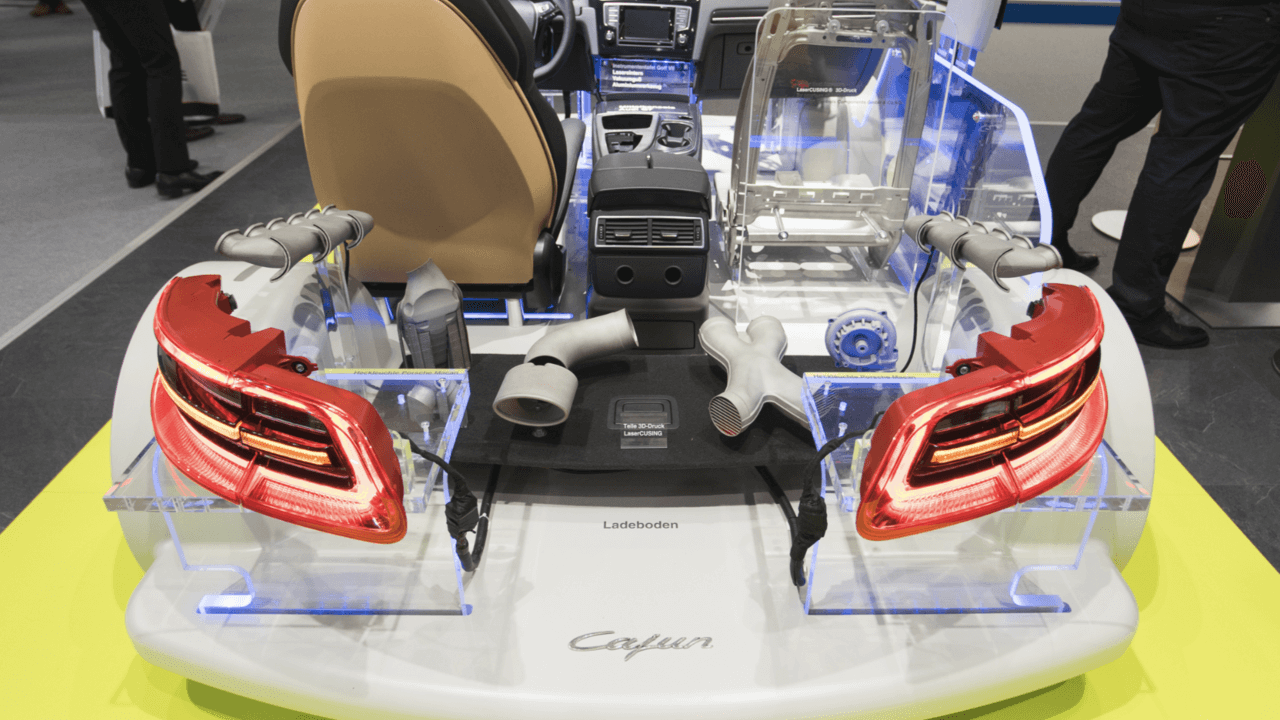

3ERP has covered many of the different ways automobile manufacturers are benefiting from the advantages 3D printing brings to the forefront. As technology is gaining a more mainstream foothold within the automobile industry, many companies are taking note, but many are using it in different capacities and for various purposes. These needs can encompass anything, […]

Pretty much every product we buy comes in some form of casing or package that needs its own set of manufacturing processes. Over the years, these packages and cases require consistent designs, often produced with the fit and geometry of the product in mind. Today, most packaging equipment is automated for efficiency and faster production […]

As the 3D printing industry grows, new trends are emerging and the overall uses of the technology are evolving. Companies around the globe are expanding their efforts in new directions and are embracing what it has to offer in end-use products, prototyping and tooling among its many other uses. Here’s a look at the specific […]

Embarking on a manufacturing project involves several crucial decisions, one of which is selecting the right CNC machine shop. This decision can influence the trajectory of your project significantly. The chosen shop’s capabilities, quality control, technological prowess, and delivery efficiency can either elevate your project or undermine it. Deciphering the Concept: What is a CNC […]

CNC machines are hugely versatile pieces of equipment, in large part thanks to the range of cutting tools they can accommodate. From end mills to thread mills, there’s a tool for every operation, allowing a CNC machine to perform a variety of cuts and incisions in a workpiece. Getting to know these cutting tools is […]

3D printed lattice structures are one of the biggest selling points of additive manufacturing. They are easy to fabricate using the unique process of 3D printing, and there are many practical benefits to using them. Lattice structures are essentially infill patterns — ways of structuring the internal geometry of a 3D printed part. Instead of […]

It is a process in which the liquefied metal is displaced into a cast, which has a hollow enclosed space in a desired form and then allows the metal to cool off and inure. The hollow cavity is denoted as cast and it gives the desired form that resembles the part being manufactured. Now the […]

Used to inject molten material, injection molding is a type of manufacturing process. Into any mold, this molten material can be injected. For the fabrication purposes of the plastic parts, it is also widely used. It is the most preferred option over other options as the method is not only efficient, but injection molding not […]

With the growth of additive manufacturing technologies, there are very few industries that have shown as much promise as that of jewelry production. 3D printing allows for the creation of novel, new forms in these fashion accessory items with a whole range of molds and sometimes direct materials processing. Additive manufacturing has also given various […]

Pressure die casting & invertment casting is not typically considered a rapid prototyping process. It requires costly equipment and a high level of expertise, and is generally suited to large quantities of metal parts. It is, in many ways, the metal equivalent of injection molding, another process favored for mass production over short-run or prototyping. […]

Commercial travel and vehicle manufacturing is about as heavy and factory-intensive as industries get. Even the smallest car is a massive undertaking with tons of components, never mind massive airplanes or locomotives. These vehicles are meant to operate indefinitely and over long periods of time (sometimes decades). This also means that many of these vehicles […]

The music industry is a massive revenue-generating behemoth, with the sales of musical instruments alone amounting to 4.5 billion dollars annually. That cost is justified because, as any musician will know, producing precise electric and acoustic instruments requires a lot of know-how and precision. And precision is where CNC machining comes in. The manufacturing process, used to […]

With the continuing growth of additive manufacturing, companies and researchers have come up with various sub-technologies, add-ons and means of optimizing prints. However, another means of achieving an optimized object is to optimize the material being used. This has given a rise to various materials made for 3D printing, all of which exhibit ideal properties […]

Computer Numerical Control, or CNC in brief, has revolutionized manufacturing. The technology has been developing for over 70 years, becoming the pillar for modern-day production and finding applications in producing end-use parts in every manufacturing sector. CNC prototype machining is one area in which this technology has proven to be a boon. CNC machining prototype […]

The energy sector is the lifeblood of modern society, powering all our devices and industry continuously. Consequently, this constant, vigilant production of energy requires all sorts of advanced equipment, from hydraulic valves for the oil and gas industry to solar cells to wind turbine parts. CNC has been crucial in creating these complex devices. Aside […]

As one of the most prominent technologies in the world, CNC machining is big business. Overall, the industry has seen growth all over the world (see our article on the industry outlook for CNC), but there are finer details worth examining for regional trends. Globally speaking, the largest machine tool consumers are China, the US, […]

CNC machining is still going strong within the world of manufacturing, showing precipitous growth even amidst the slew of competing technologies and new entrants. Even so, CNC machining is a wide ocean with many varying interests and trends within it. With so many sub-technologies it can be hard to keep track of what the latest […]