In a recent game-changing operation in healthcare and the 3D printing industry, a team of surgeons in South Africa has completed a successful middle ear transplant using titanium. Surgeons at the Steve Biko Academic Hospital in Pretoria, South Africa reconstructed the hammer, anvil and stirrup ossicles for a patient from 3D printed titanium. The team […]

For CNC machining projects, aluminum is one of the most popular material choices due to its desirable physical properties. It is strong, which makes it ideal for mechanical parts, and its oxidized outer layer is resistant to corrosion from the elements. These benefits have made aluminum parts common across all industries, though they are particularly […]

Bringing a product design to market – no matter how physically large or small – is no easy feat. Working out a 3D CAD model of your new design is half of the battle, but the steps along the way can make or break your project. In this article we have listed the 5 steps […]

For many businesses, the prospect of hiring a manufacturer for a CNC machining project can seem daunting. Machining is a complex process that requires comprehensive planning, a skilled machinist, and sometimes a large block of material. All of those things require time and money, so businesses often see machining as beyond their financial reach. This […]

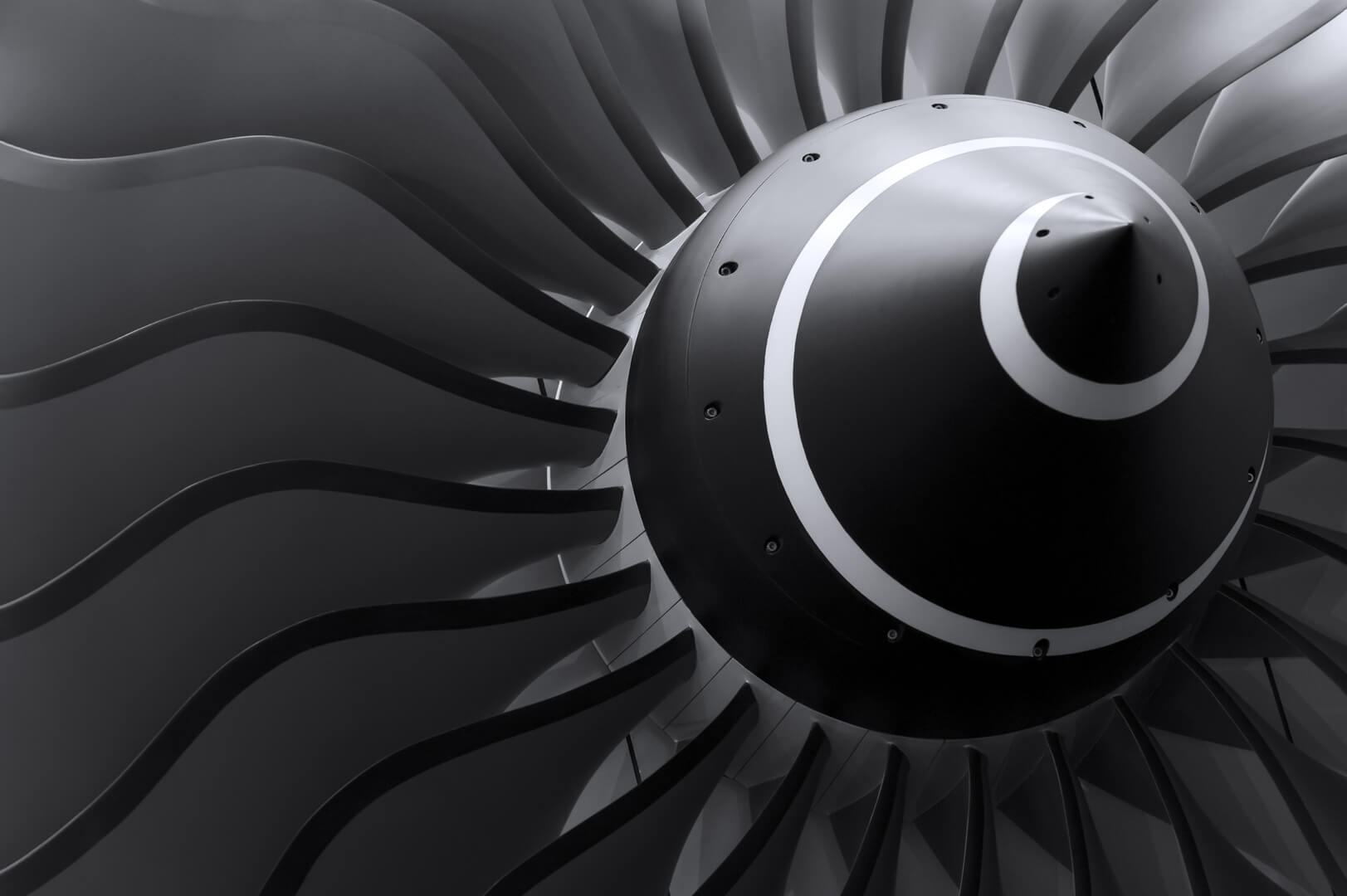

From the earliest days of additive manufacturing, providers of 3D printing hardware and materials have identified the aerospace industry as an important target for their products. Aircraft, as highly complex systems with a diverse array of parts, stand to benefit from cutting-edge developments in production tools and materials, especially those that can reduce the weight […]

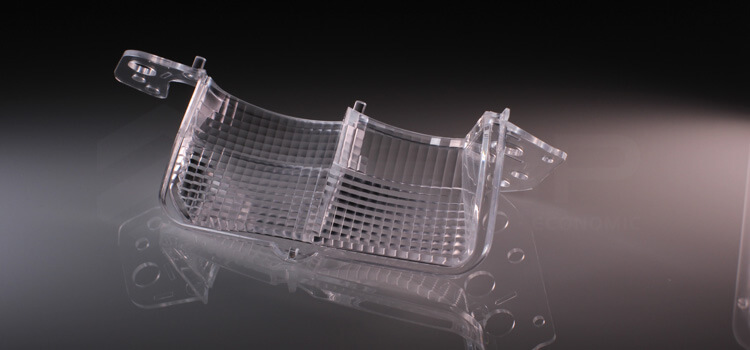

Stereolithography (SLA) is a versatile and high-quality manufacturing and prototyping process. Although less widely used than extrusion-based additive manufacturing technologies like Fused Deposition Modeling (FDM), SLA was actually the original incarnation of 3D printing, first appearing way back in the 1980s. Today, desktop SLA printers have been popularized by brands like 3D Systems and Formlabs, […]

Innovations in CNC machining, additive manufacturing and casting technologies are giving companies, prosumers and consumers an unprecedented level of design options. However, with so many technologies on the market, the question remains: how are they faring in terms of growth and which industries are employing them most prominently? Here, we take a look at the […]

Every industry and application is different, but metal parts often look and feel superior to their plastic counterparts. Metal provides a gloss and sheen, as well as the appearance of strength and durability. Plastic is incredibly useful, but metal often wins in the overall quality stakes. On the other hand, plastic parts are often much […]

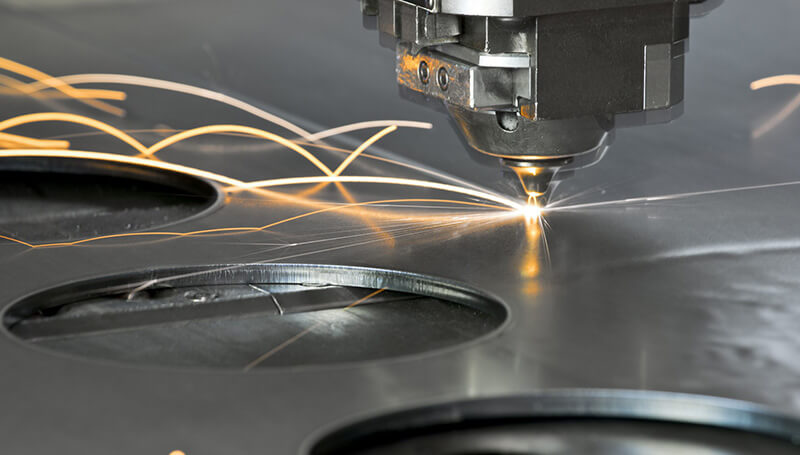

Laser cutting has been around since the 60’s but now it’s as relevant as it has ever been due to its growing usage within industrial processes. This non-contact process uses a constant beam of light to create heat and pressure which then reshapes/distorts various materials with precision as the cutting head moves over the material […]

3ERP offers a wide variety of prototyping processes, from industrial-grade CNC machining to FDM 3D printing. For small volumes of plastic parts, however, businesses are often torn between injection molding — a commonly used process in which molten material is injected into a metal mold — and vacuum casting, in which more affordable silicone molds […]

Precious metals such as gold, silver and platinum form a major cornerstone of many products. While they serve as core components for electronics, energy creation and the automotive industry, they are most popular in the production of jewelry and accessories. These metals are often irreplaceable in their respective roles and embody a diverse range of […]

Whether your prototype is for user testing or investor pitches, injecting a splash of color can turn a half-finished idea into a part that looks ready for the market. 3ERP offers a range of coloring options for prototypes and end-use parts, offering finishing services like painting, tinting and anodizing, as well as color-friendly manufacturing processes […]

For a long time, making toys in an amateur capacity was a difficult thing to do. You could use wood, or you could piece things together from recycled components, but high-quality toymaking was a practice exclusively carried out by big and medium-size toy companies: giants like Mattel and LEGO and the like on the higher […]

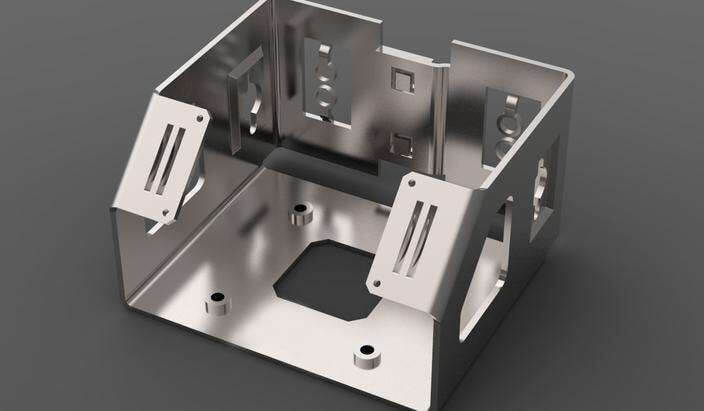

Sheet metal fabrication is a handy set of manufacturing processes used to create parts from flat pieces of metal. Sheet metal comes in a range of materials and thicknesses, and can be used to create parts like appliances, enclosures, brackets, panels and chassis. For those new to sheet metal fabrication, the process can seem daunting. […]

Aluminum is one of the most used metals in the world, along with iron, tin and copper. It’s a cornerstone of so many goods and industrial applications, and it’s easy to see why. It’s lightweight with a density far lower than a lot of its counter parts. It’s durable and a great conductor for both […]

Metal casting, like all industrial methods, necessitates a fair amount of accuracy and fidelity towards the intended design. However, things are rarely as simple as executing a method of production because uncalculated variables can rear their heads and ruin a design with bumps, tiny gaps and today’s topic: shrinkage.

Construction printing has seen a lot of great initiatives in the past few years, from 3D printing drones to massive cable driven, infinite-build machines. However, taking construction to the next level isn’t solely about improving the hardware but also the input materials. It’s no secret that the construction industry can be wasteful, being one of […]

Creating a medical device is an enticing prospect. Although competitive, the medical device market can be extremely lucrative, with innovative devices capable of making millions for their creators. Needless to say, such devices can also save lives. But designing a medical device takes a lot of effort. There are more considerations, potential pitfalls and stringent […]

Both engineers and machinists play an instrumental role in the production process. The engineer designs a product, and the machinist — while attempting to follow the engineer’s precise instructions — turns a piece of metal or other material into the intended product. In an ideal world, this should be a smooth operation: engineers are required […]

The machine-friendliness of aluminum has made it the number one metal for machining. Its material properties make it easy to mill, drill, cut and punch, while aluminum machined parts can be strong, durable and aesthetically pleasing. All in all, aluminum is the most machinable metal on the market. Despite this, aluminum is far from perfect. […]

The Hennessey Venom GT just hit 270 MPH on a runway. The Koenigsegg One:1 thinks that’s cute. And that’s because it should be able to hit 280 MPH. Oh, and it can go around corners like mad. Welcome to the new king of speed and a fast (no pun) look at the technology used to make these cars break new […]

In some form or other, cars have existed since the nineteenth century. Their introduction changed civilization, giving fast personal transport to large sections of the population while creating a new workforce and introducing a new aspect of popular culture. The automotive industry now exists everywhere. Although the U.S. dominated automotive production in the early 20th […]

Digital manufacturing is making a big impact on many areas of medicine, from small things like the machining of aluminum test tube holders to futuristic practices like the 3D printing of titanium implants. Of the many medical applications of digital manufacturing, one particular area coming on leaps and bounds is the creation of anatomical models […]

Recognized for being incredibly lightweight and durable, aluminum is one of the most popular materials used in the production of functional parts and prototypes. It also offers impeccable corrosion resistance, thermal and electrical conductivity, and also retains dimensional stability even in high temperatures and harsh environments. Since this particular metal has such a high melting […]

Whatever your sport — be it running, football, tennis, cycling, swimming or something else — proper equipment can always help improve performance. Even in a relatively basic sport like running, possessing equipment like a technologically optimized pair of shoes and a breathable outfit can be the difference between winning and losing. On the other end […]

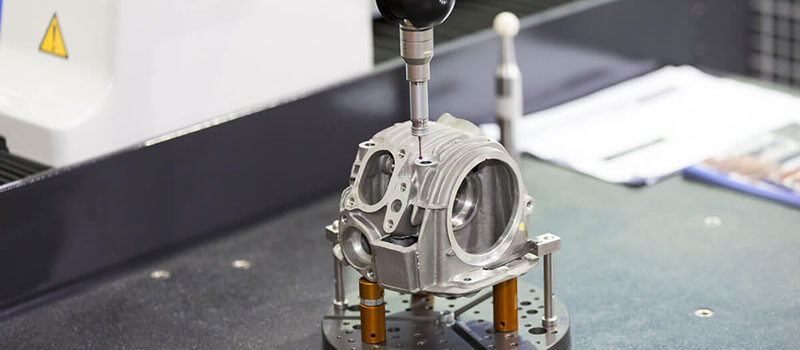

When it comes to manufacturing use-end parts and functional prototypes, it’s extremely important that the physical dimensions and geometric characteristics of the object match that of the 3D model. Even if a measurement is just slightly off, it can jeopardize the entire production process and set you back to square one. That’s why 3ERP offers […]

When you’re in need of metal prototypes or parts with superior mechanical properties and specialized aesthetic design, anodizing aluminum is an excellent option. The anodizing process forms a layer of oxide on a metal part, effectively increasing corrosion resistance, and also enhancing visual qualities and keeping the surface from being scratched. Anodizing aluminum is an […]

Additive manufacturing, otherwise known as 3D printing, is beginning to make its mark on a wide range of industries, from medical device manufacturing to aerospace. One of the biggest beneficiaries of additive, however, is the automotive industry, in which car manufacturers are using 3D printing to prototype components, create libraries of spare and customized parts […]

Seeing rust on an iron or steel surface can be cause for alarm. Needless to say, if parts of your car start to turn that distinct shade of reddy brown — a transformation that occurs when iron undergoes the process of oxidation — you might be due a trip to the mechanic… if not the […]

In nearly every single instance of product development, no matter what industry it’s for, prototyping is a necessary stage that will ultimately determine whether your production efforts will be successful or not. The rise of rapid prototyping has made it both easy and affordable to quickly iterate a plastic prototype. However, there are a range […]

When it comes to mass production, traditional manufacturing methods still reign supreme over other production techniques. However, rapid manufacturing and prototyping has become an integral piece of the design and production process, helping businesses actualize their concepts in a quick and cost-efficient manner. Rapid manufacturing is usually centered around additive manufacturing (more popularly known as […]

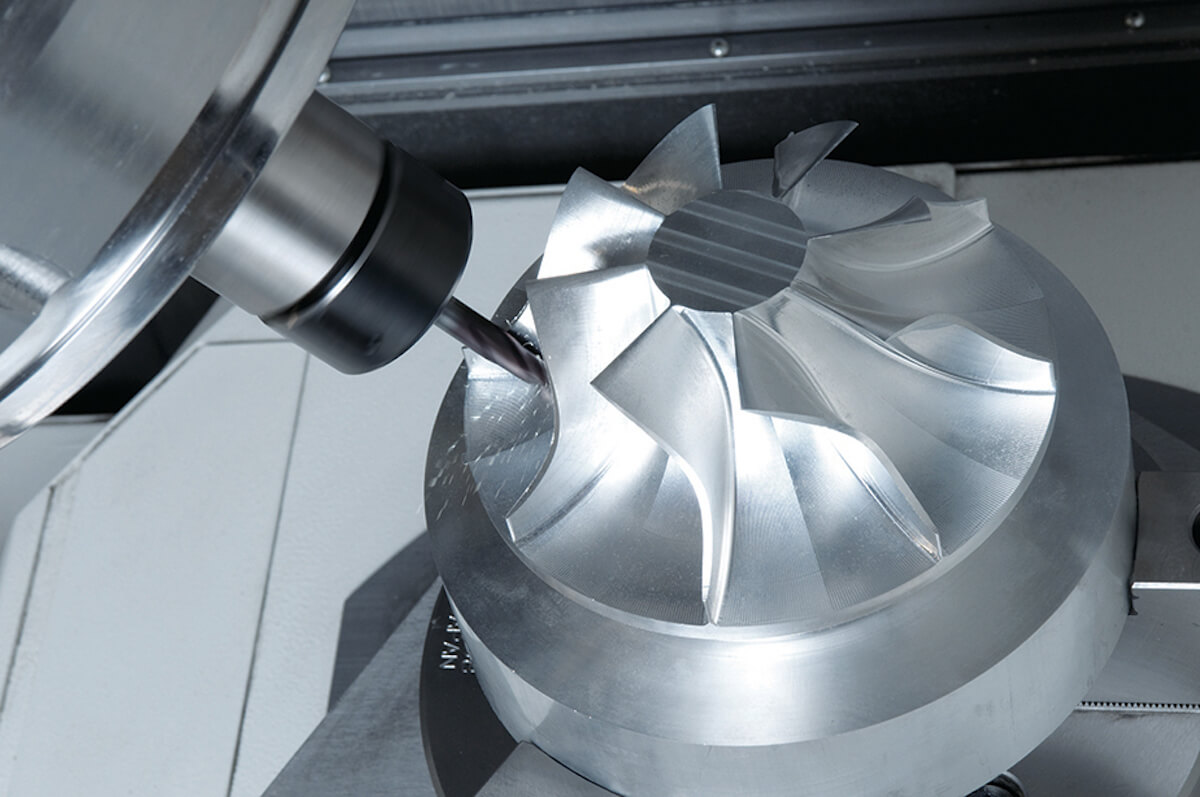

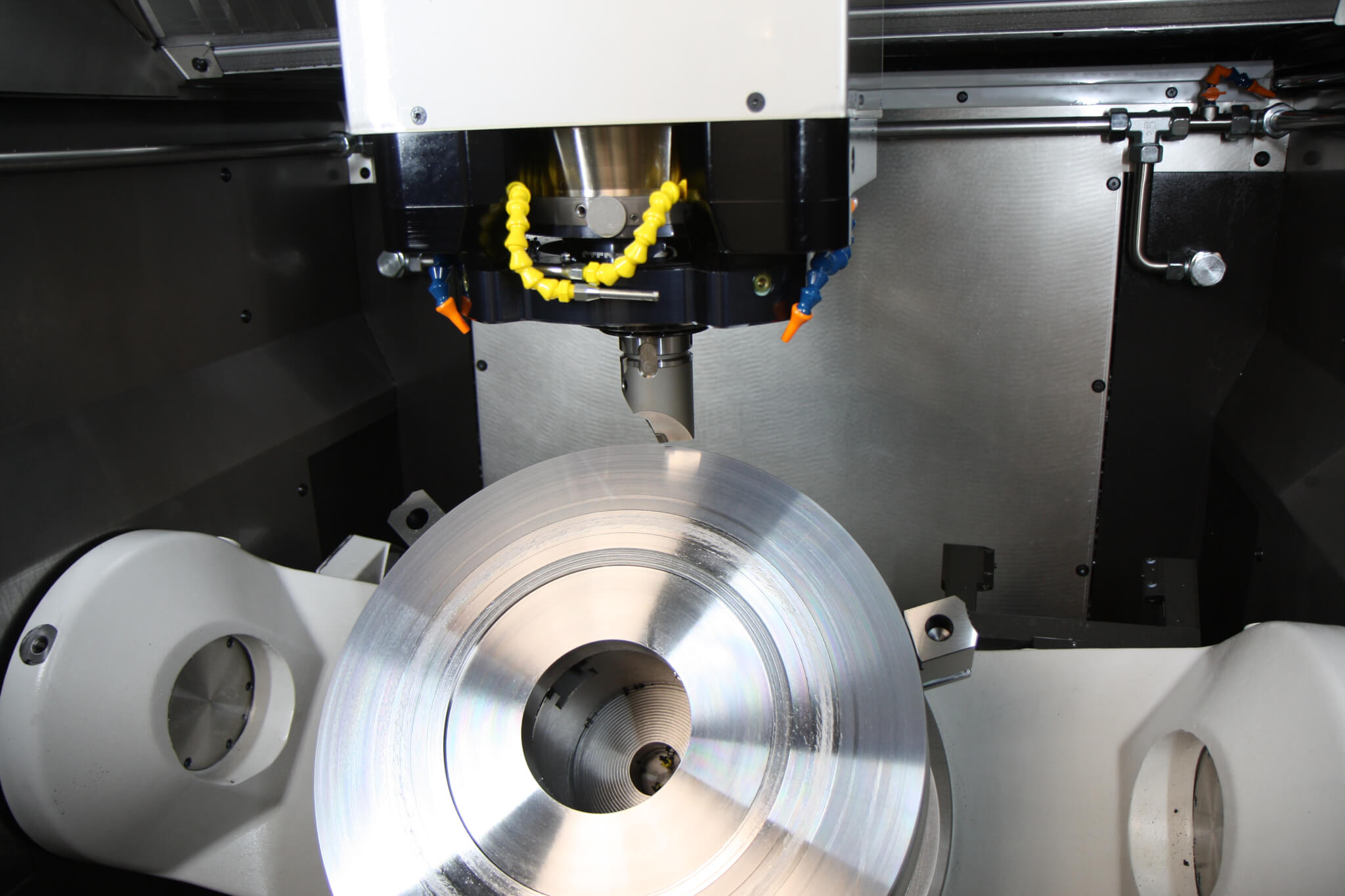

With the rise of intricate, small-scale parts, manufacturing evolves daily, now heavily relying on advanced techniques like 5-axis CNC machining. Traditional methods often fail to meet these complex demands, leading industry professionals to adopt these sophisticated processes. Any multi-axis CNC method, such as the 5-axis machining, brings in a whole new dimension of capabilities and […]

Aluminum is an important industrial raw material. However, because of its relatively low hardness and large thermal expansion coefficient, it can easily deform when being machined into thin-walled and thin plate parts. In addition to improving tool performance and eliminating the internal stress of the material in advance, there are several steps that can be […]

The CNC machining process is a great way to turn innovative designs into precise working models. However, users can only enjoy the full advantages of the process if they use the right CNC machining materials. Using the most suitable material can produce products that exceed your expectations. In contrast, not choosing the best CNC machining […]

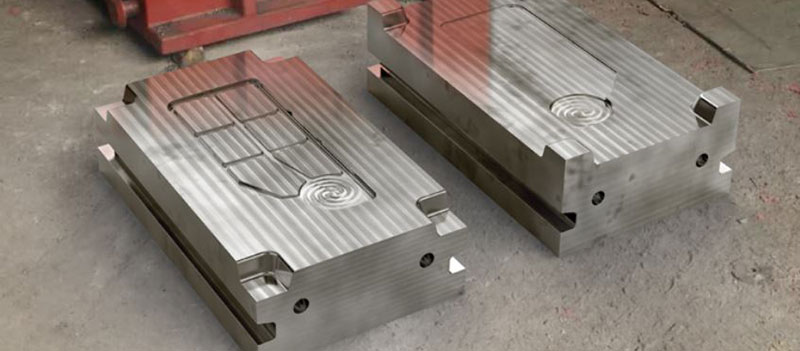

What is on-demand rapid tooling and low-volume molding? From the dashboard of your car to the lid of your coffee cup, billions upon billions of everyday objects are brought into the world by molding, a process in which a hollow container is filled with a molten material to produce large numbers of a single object. […]

CNC milling is one of the most popular options for manufacturing prototypes and parts that entail cutting or drilling. The technology utilizes a rotating cylindrical cutting tool to cut or drill a design from metal or plastic material. Compared to traditional manufacturing techniques, CNC milling offers advantages such as high production speed, greater precision, and […]

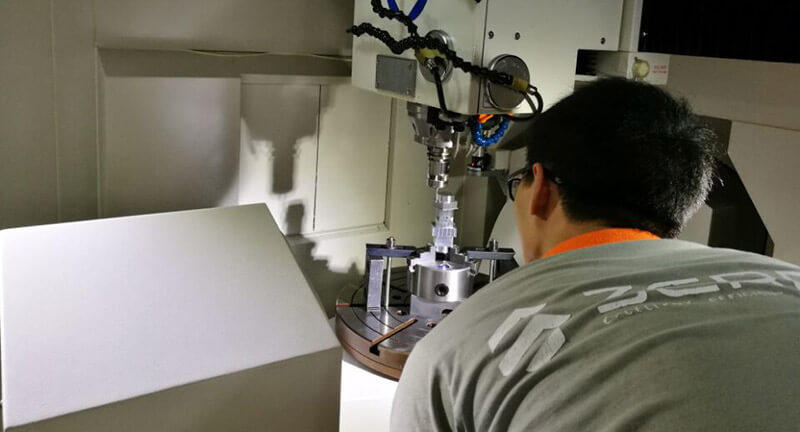

At 3ERP, we have a great engineering team who are ready to take challenges. And try to get the best result for our customers. Getting experiences from project to project, with advantage 4-, 5- axis CNC machines, we are able to handle the most difficult prototypes and production parts. Learn more about our CNC machining […]

While the outsourcing of mass production to China is now standard practice for many companies, the outsourcing of prototypes — preliminary versions of products that will be mass produced at a later time — is less common. Like all business decisions, outsourcing prototypes to China has its pros and cons, but when the right steps […]

Prototypes are of critical importance in the development and production of a wide range of medical devices, including anatomical models, hand-held appliances and larger pieces of equipment. Here are the five most utilized rapid prototyping methods commonly used to quickly create prototypes for the medical field. 5 Popular Rapid Prototyping Techniques Here are five methods […]

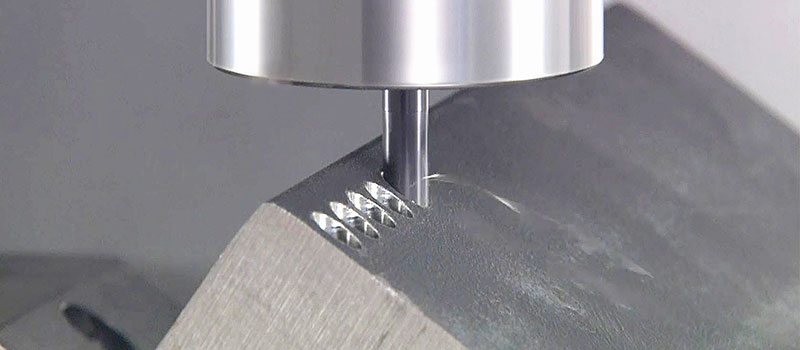

Fundamentally, you need precision machines. If your machine tolerance is +/- 0.05mm, but you try to make some parts with +/-0.01mm tolerance, that’s not going to happen for sure. An ant won’t be able to lift an elephant. Once you have precision machines ready, does that mean you can start to make precision parts? Not […]

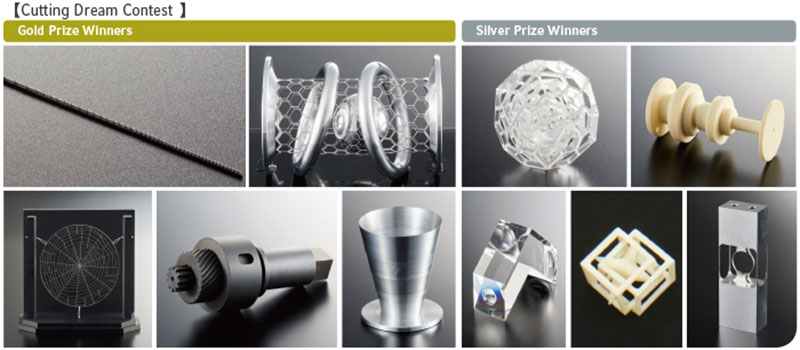

We will be posting more winning workpieces in the next blogs. 3ERP provides cutting-edge CNC Machining Services , if you are curious how these workpieces be made, please read our latest blog “how to make precise parts & mold cavities”.

The mold industry is one of the most long-span industries, and it has relationship with all areas of the manufacturing industry. In modern times, manufacturing and mold are highly dependent, and countless product components are manufactured by molding (injection, blow molding and silicone) or casting (mold casting, fining and spinning). No matter what application, the […]

After your team’s design has been validated with the development of a prototype, it’s time to look forward to the next phase. The plan for this next stage typically includes focusing on a solid course of action that is designed to bring the product to market in a way that positions it for success. Orchestrating […]

One of the steps involved in taking your concept from the prototype development stage to market is determining the lead times involved in its manufacture. Another important element to consider is the price quote. There are a number of — sometimes surprising — factors that could affect both the price you’re quoted and the lead […]

Prototyping is an essential element of the design and engineering process. Traditionally, though, it has created challenges as design teams strive to create makeshift models that provide a valid basis for a particular concept. This has, in the past, required nearly the same processes, costs, tooling and setup as the final product, making prototypes a […]

A bringing an idea from the design stage to the prototype process means that it must undergo a great deal of work. From tweaking numbers and moving components to changing materials and adding features, once a design makes it to the stage where it’s ready for a prototype to be created, it is a common […]

If you look at the tail light of your car, you might notice that, instead of making the whole lamp in red, it usually contains a clear, transparent area. That’s because red color is needed for brake indicator lights, while the transparent area gives enough light when your car is reversing

Moving a product from the design phase to its market introduction is a process that has specific steps. Knowing what to do to make it as quick, accurate and valuable as possible is the key to its success. Once a design has been completed, what are the next steps? It’s important to talk to an […]

An interview with Ronan Ye, Founder and General Manager of 3ERP Q: Why did you found your company, 3E Rapid Prototyping (3ERP)? What goals did you want to accomplish? A: I started 3ERP because I like rapid prototyping and manufacturing. And because it’s something I am good at doing. But there are other reasons, too. […]

Aluminum is an essential element that is behind only silicon and oxygen in terms of its abundance in the earth’s crust. While materials like steel and copper have a longer use history, today aluminum is found in numerous applications across a wide swath of diverse industries. The History of Aluminum Aluminum ores had previously been […]

The Use of Laser Cutting in Sheet Metal Prototyping Though there are a number of ways that sheet metal can be shaped and cut, few are as precise, reliable and cost effective as laser cutting. The technology involved in laser cutting is so effective that a continuation and improvement of its future capabilities is inevitable. Categories […]

ISO is the acronym for International Standards Organization. ISO 9001 is a common standard that many manufacturers seek certification for. ISO 9001 certification shows the world that your manufacturing concern takes quality seriously, and is important in every phase of business that includes: People Facilities Training Services Equipment Company Benefits of ISO 9001 Certification Becoming […]

When it comes to CNC machining manufacturing, fractions of inches can make the difference between a successful product and losing a customer. There are several ways to promote quality control (QC) in CNC production. This post will explore some of these. What is CNC Machining Quality Control? Quality control is the process used in CNC […]

As with most manufacturers, you are likely on the lookout for ways to save money, but doing so is often easier said than done. Firms typically take advantage of the most obvious ways to cut costs early on, and struggle to find more subtle chances for saving. If you manage to continue lowering costs over […]

3-D printing has gained a great deal of traction in the past few years. Its popularity is expected to grow as the techniques become more refined and focused. Unlike some experts warned, though, 3-D printing is not poised to replace CNC machining. Forward-thinking companies combine the properties of both techniques to develop strategies that meet […]

Opportunities coexists with risks -Advice on how to outsource prototype manufacturing to China We wanted to share some thoughts on how overseas companies can benefit from outsourcing prototype manufacturing to China. Manufacturing and importing from China can seem daunting, especially if you are a comparatively new start-up or SME and have never thought about outsourcing […]

Name:Type 99 Main Battle Tank Model Scale: 1:24 Process: #4axis, #5axis #CNCmachining Material: Stainless steel 304 Components: 767

Types of Materials To Use In The Diverse Method Of Vacuum Casting EXCERPT Vacuum Casting is a very diverse method of replicating objects. It can be used for both the casting or prototypes or mass production of distributable products. ARTICLE Vacuum Casting may be used with a multitude of materials. This method of casting is […]

How Rapid Manufacturing Beats Typical Industrial Wait Periods EXCERPT Do you want to be the first to market for your products? Of course you do, because then you will lead the industry. Learn how rapid manufacturing beats typical industrial wait periods. ARTICLE Speed kills. Global manufacturing continues to advance and if you are slow to […]

Finding the Right Tools for Prototyping on a Budget Need to get your prototype off the ground, but funds are tight? Here are some tools and tips to get going. Market prices have come down as technology has matured, and rapid prototyping and manufacturing prices are competitive. Instant quotes reduce the wait time for feedback […]

Rapid prototyping and 3D printing capabilities have helped many companies to turn many great ideas into amazing products quicker than ever before. A product that can take days to model can now only be visualized in a matter of minutes or hours. That feature has enabled many manufacturing firms to reduce their product lead times […]

Rapid prototyping refers to a set of processes that can easily fabricate a three-dimensional object into a prototype, directly from a CAD file through additive deposition of single cross-sectional layers of the part. It was introduced in late 1980’s.RP can be defined as a group of processes used to fabricate easily to a physical working […]

Acrylic (PMMA) is a highly desirable material due to its strength, toughness, and transparency. But relying on conventional machining processes to cut acrylic can be a complicated procedure: the material is highly fragile and any excess force can cause unwanted breakages. CNC machining, however, offers a reliable way to fabricate acrylic parts safely, with a […]