What is on-demand rapid tooling and low-volume molding?

From the dashboard of your car to the lid of your coffee cup, billions upon billions of everyday objects are brought into the world by molding, a process in which a hollow container is filled with a molten material to produce large numbers of a single object.

Since molding allows multiple copies of a single product to be produced, it is usually associated with mass manufacturing. However, with new digital manufacturing technologies like additive manufacturing (3D printing) and CNC machining, it is now possible to create a kind of prototype mold in an extremely short space of time. This process is known as rapid tooling.

While molds created via rapid tooling are not usually used for the mass production of objects, they can still be used to produce many copies of a single item. For this reason, low-volume molding — the creation of small quantities of molded products — is often carried out in conjunction with rapid tooling, giving customers a batch of a prototype product rather than just a single copy.

The advantages of rapid prototyping and low-volume molding are numerous. What follows is an overview of some of the key benefits of the two related processes.

Advantages of rapid tooling and low-volume molding

One of the biggest advantages of rapid tooling is right there in the name: speed. Since digital manufacturing technologies like additive manufacturing and CNC machining can be used to create molds in a very short space of time, rapid tooling service providers can offer fast turnarounds on products made with those molds. For businesses, that means getting hold of products faster and getting them to market sooner.

There are also big cost advantages to rapid tooling. Since the bulk of the process involves just a computer and an automated machine like a 3D printer, rapid tooling ends up being far cheaper than traditional toolmaking, with cost savings passed on to the customer. This results in affordable molded products even in low volumes.

Besides time and cost savings, there are other more specific benefits to rapid tooling and low-volume molding, some of which relate to the digital manufacturing processes used to create the molds. Since CAD is used to create the mold, manufacturers can ensure consistency across several molds by simply reusing the same digital file. Digitally creating these tools also allows for easy optimization of cooling channels and other features, and for quick modifications on future molds.

On-demand rapid tooling and low-volume molding is also, for several reasons, an effective precursor to mass manufacturing a product.

For one, rapid tooling can be used to mold products in a range of materials, and since the molds can be produced extremely quickly, manufacturers can make small quantities of a product in different materials and finishes, helping the customer decide on the ideal configuration for their product.

Secondly, such prototype molds are useful for bridge production, when, for example, a customer needs to get the first batch of products to market before regular tooling has been completed. Low-volume molding of a product can also help a customer iron out any previously unnoticed flaws in a product before moving on to mass production.

On-demand rapid tooling and low-volume molding with 3ERP

With many years of experience in the rapid prototyping industry, China’s 3ERP is an expert in rapid tooling and low-volume molding, possessing both the skills and equipment to reap the advantages of the processes.

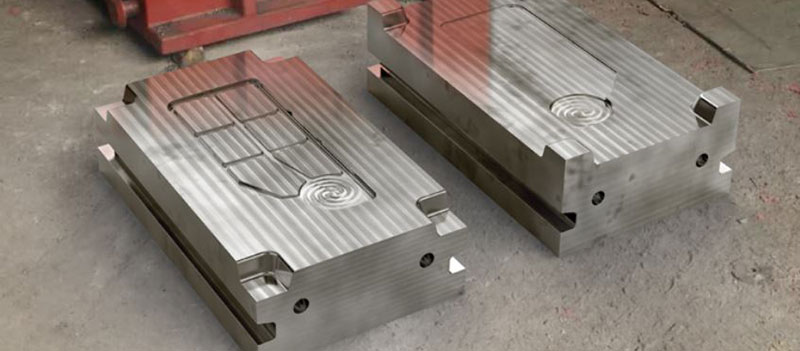

In terms of its rapid tooling capabilities, 3ERP is able to offer two metal options: aluminum mold tooling, which is highly cost-effective and suitable for prototypes, and steel mold tooling, which can be used with abrasive, corrosive, and engineering-grade plastics and which can be used to make millions of molded parts — ideal for bridge production. Molds can be made according to DME, HASCO and LKM standards.

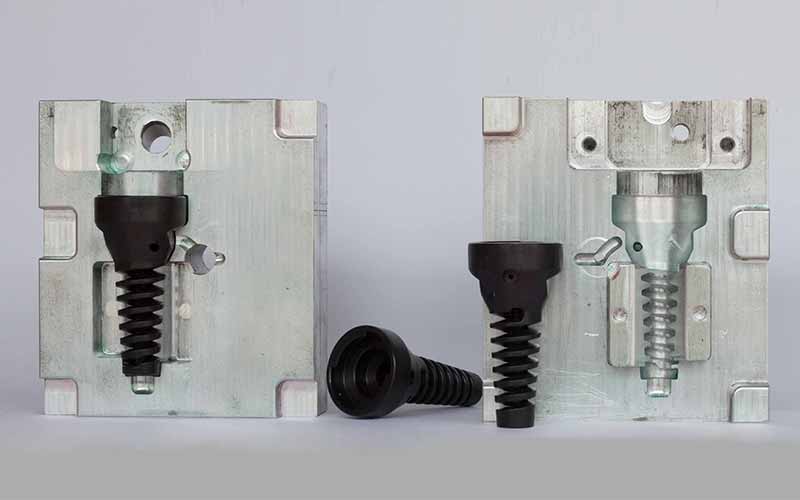

Those metal mold options are, however, just the start of the material possibilities offered by 3ERP. When the molds are ready for use, customers are provided with significant flexibility in the ensuing low-volume molding stage.

Molded products can be made from a wide range of plastics, including nylons, polycarbonates and thermoplastic elastomers, and are available in a large number of colors and finishes, including laser finishing and heat staking.

Best of all, customers around the world can expect their prototype molded parts in as little as 15 days. Get in touch with 3ERP to see if its rapid tooling and low-volume molding services are suitable for your needs.