What is Rapid Tooling?

Rapid Tooling is an advanced method that involves the practice of Rapid Prototyping techniques and conventional tooling to yield a mold quickly. This technique is specially intended to streamline the mold structure for low cost within a deadline. Most often this is used in the field of rapid injection molding when it comes to the low-volume production need.

In this process, the molded parts are manufactured from CAD data and the most important fact is that it is produced in less time at the best pricing range. We can say this is the most convenient and cost-efficient process in comparison with the old-fashioned manufacturing methods. It is the most effective technique to manufacture injection molded parts.

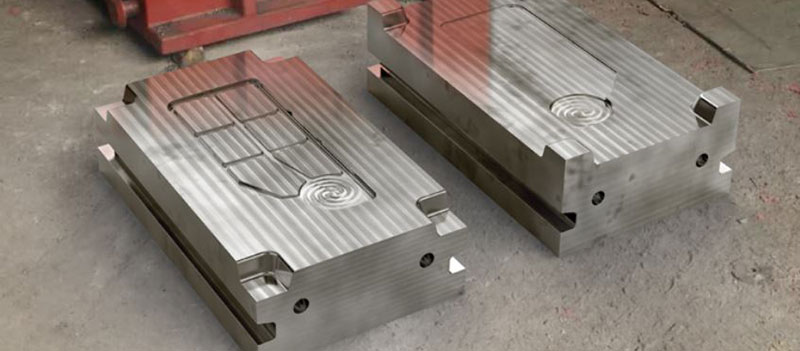

In this rapid tooling procedure, many cavities and cores inserts share one same mold base which leads to reducing the lead time. It is also known as prototype mold or low volume production mold. It depends on the client’s demand and accordingly the manufacture will provide the molded parts.

There are diverse designs based on different quantities. However, you need a low volume or high volume production; a professional manufacturer will fulfill your requirements. Usually, the tooling life is about 100,000 shots for rapid tooling. It also depends upon the structure of the tooling.

When we compare the rapid tooling process with another traditional mold making, it can help you save 40% to 50% of the cost and 40% to 60% of the time. In order to get the best Rapid Tooling Services, you must engage a responsible manufacturer that always examines product structure, tooling building viability, and potential quality risk to make you satisfy. As a result, it ensures the tooling is benign.

As a business person, if you seek to market your product sooner, you should opt for rapid prototyping to make the parts readily available for testing. As we know that the manufacturing industry has involved many innovations currently and among which several rapid prototyping methods help the design team during the product development phase. All thanks go to rapid tooling that produces parts quickly to test and validate them before going into production tooling.

Applications of Rapid Tooling-

When it comes to the scope of application of tooling, a lot of options we have. With the advent of technology, it is continuously growing.

It helps to create both metallic and non-metallic molds

It makes casting shapes and cores. Also, it can make electrodes for EDM, marking stamps, hybrid patterns for casting, etc. Most importantly, all these can be made at a low cost as well as in an effective way. Hence, you can able to market your products as soon as possible.

How Rapid Tooling Services Work?

In this process, usually, the raw melted plastic injects into the mold where it cools and hardens to become the final required parts. Once the part has cooled, then it will remove and finish.

Why Rapid Tooling Services are in Demand?

- Lessens production cost and lead time compared with the traditional mold

- Different surface finishes can be accessed, including Texturing, Polishing, Sandblasting, etc.

- Possible to customize the tooling as per the product design and keeps the color constancy of the products.

- With low volume production, it can be also a good solution for huge volume production mold

In a nutshell, this tooling is the best yet affordable solution. There are different manufacturers providing effective solutions, however, In order to get the best quality of Rapid Tooling Services, get in touch with 3ERP for a free quote. We’ll gladly offer advice about your best options. Combining our expertise, engineering capabilities, and advanced technology we can offer rapid tooling solutions.