Seeing rust on an iron or steel surface can be cause for alarm. Needless to say, if parts of your car start to turn that distinct shade of reddy brown — a transformation that occurs when iron undergoes the process of oxidation — you might be due a trip to the mechanic… if not the car dealership.

Not all oxidation is bad though. In fact, one of the reasons why aluminum is such a useful and versatile material is precisely because it oxidizes immediately upon exposure to oxygen. Although this oxidation is chemically similar to the rusting of iron, it actually protects the underlying structure of the aluminum by forming a durable outer surface that prevents the spread of further oxidation.

With rusted iron, on the other hand, the oxidized surface eventually flakes off, allowing more of the underlying iron structure to oxidize and ultimately degrade.

Building upon the naturally self-preserving oxidization process of aluminum, chemical engineers in the early 20th century created a process that essentially thickens the layer of protective oxide on the surface of metal by passing an electric current through the metal in an electrolytic acid bath. That process, now known as anodizing, can be carried out on aluminum, titanium and other metals.

Improve Your Electronic Products by Anodizing

Although used in many industries for many different reasons, anodizing has become a vital tool for electronics manufacturers. This article will explain some of the ways anodizing can help you create a superior electronic device using 3ERP’s trusted anodizing processes.

Vibrant colors

Anodizing is generally seen as a great way of applying color to aluminum and titanium products. That’s because the layer of oxide created by the anodizing process is porous, allowing dyes to be neatly funneled into the gaps. When the anodized layer is sealed after the application of the dye, the color is much more likely to endure than paint, which can easily chip since it is not embedded within the ‘pores’ of the surface.

A huge range of colors and shades are possible using the process of anodizing. Pale and pastel-like tones can be achieved even with very thin anodized layers, while deeper, more saturated hues can be achieved with thicker layers.

Most modern Apple devices feature anodized finishes, hence their surface durability and high-end appearance in a range of colors.

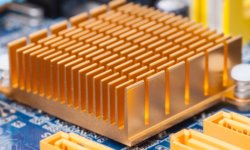

Electrical and thermal insulation

One of the more practical benefits of anodizing — particularly the process of sulfuric acid anodizing (Type II or Type III) — is an improvement in electrical and thermal insulation, since aluminum oxide is a better insulator than aluminum.

This means that anodized electronic products, whose surfaces will not conduct an electric current, can offer safety advantages over products that have been subject to other surface finishes or those that have not been treated at all. This is obviously a massive draw for manufacturers of consumer electronics: not only do anodized surfaces look great, they can also keep the current where it is supposed to be.

The thermal insulation offered by an anodized surface is also beneficial for electronic products whose internal components generate heat.

Corrosion and wear resistance

In addition to improving the appearance and safety of electronic products, anodizing can also improve a product’s resistance to wear and corrosion.

Although an anodized surface is more likely to crack under extremely high temperatures, the oxidized outer layer of an anodized product will possess better corrosion resistance, relative to the thickness of the anodized layer. For example, an MP3 player with a thin anodized coating will offer marginally improved corrosion resistance compared to an untreated product, while another MP3 player with a thick anodized coating will offer significantly improved corrosion resistance.

An anodized surface also effectively improves a products resistance to wear and abrasions, providing a longer shelf life and superior appearance over time.

What 3ERP can offer

3ERP possesses years of experience in surface finishing, offering processes like polishing, painting, tinting and powder coating. It also offers comprehensive anodizing solutions, including four different variations on the process:

Anodized Type I: Uses chromic acid to produce a thin and ductile anodized layer

Anodized Type II: Uses sulfuric acid to produce a medium-thickness anodized layer suitable for coloration

Anodized Type III: Uses sulfuric acid to produce a thick anodized layer suitable for coloration

Chemical Film / Alodine: Coating part with alodine to produce anodized-like results

Get in touch with 3ERP to find out how the company can improve your electronic products via the process of anodizing.