Here at 3ERP, we often receive Requests for Quotation (RfQs) where the customer has a passionate vision for a product but lacks the technical skills to create a digital 3D design that is suitable for production.

Unfortunately, if the customer cannot submit a usable 3D design — or at least create a technical drawing that we can follow — then we simply cannot make the product. Because while we can offer advice and make small adjustments to designs in order to improve manufacturability, our job is to manufacture parts, not design them from scratch for the customer.

In many cases, customers trying to submit incomplete RfQs need the help of a specialist in product design or industrial design: someone who can develop the customer’s concept and turn it into a watertight design that is ready for the factory floor. As a rapid manufacturing company, we are able to provide DFM suggestions. If you want to create a product from idea, the first thing is to talk to product design company.

This guide explains the basics of product design and provides examples of when you might need a professional product designer to bring your project to fruition.

Do you need professional product design services?

If you’ve never designed products for manufacture, or if you’re intending to work with a new and unfamiliar manufacturing process, you may need to the help of a professional product designer who knows the ins and outs of the factory floor.

Designing parts for manufacture is simpler than it used to be. CAD/CAM solutions like SolidWorks, CATIA, Pro/E, and UG make it easier to design physical objects from scratch, while savvy entrepreneurs can also design new products by 3D scanning and reverse engineering existing items, giving them a foundation to build on.

But there’s a big difference between making a 3D CAD design that looks right, and one that can actually be fabricated using manufacturing equipment.

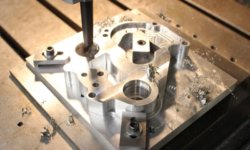

If you aren’t overly familiar with the principles of Design for Manufacturing (DfM), you might struggle to achieve the latter. Of course, you can read up on CAD and DfM, but an expert touch ensures that every feature of a product can be smoothly realized by cutting tools, molds, and other factory equipment.

However, professional product design isn’t just about manufacturability. Product designers with experience in your industry should be able to develop a design with improved end-use functionality and improved aesthetics, both of which can make a huge difference to the product’s success on the market.

Checklist: Is your RfQ complete?

You can’t submit a vague idea for a product and hope the manufacturer will fix everything up for you. Before submitting an RfQ, ask yourself if you’ve included the following:

- A watertight CAD file designed specifically for the desired manufacturing process that takes into account the physical limitations of the process or a clear drawing with measurements

- A list of all materials required

- Specifications for any surface finishes required

- The number of units required

What is a product designer?

At the most basic level, a product designer is a professional who turns a concept into a complete design that is ready for manufacturing. However, product design companies often do much more than provide sketches and CAD files.

Note that the field of “product design” can overlap significantly with “product development” — a more general term that may involve tasks like business strategizing — and “industrial design,” which focuses more specifically on whether a product is suitable for mass production using standard factory processes.

A product designer can be part of a company’s in-house team, but in this article we are referring mainly to third-party product designers who offer their services to customers who need help developing their product.

What are the main aspects of product design?

A product design company may offer a wide range of services, from early concept development to handling the exchange of the design to the manufacturing partner.

Product design tends to focus on three main aspects:

- Aesthetics: How the product looks

- Ergonomics & Function: How the product works and how users interact with it

- Manufacturability: How the product can be physically made on the factory floor

Customers can usually choose which specific services they need from the product designer. They may need help with the concept itself, which can entail concept experimentation and risk analysis. This relates to business strategy — market assessment, budgeting, etc. — which is not strictly part of product design but may be handled by the same company.

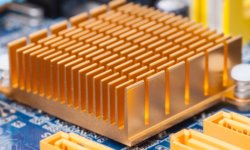

Some customers may need more help with the engineering and industrial design side of things, commissioning the product designer to design, refine, validate, and simulate certain features, identify materials and finishes, and get the product ready for manufacture. This is the core element of product design.

Additionally, some product designers will carry out early-stage prototyping and testing for the customer, although this task may be handled by a dedicated prototyping specialist.

They may even take care of delivering the project to a suitable manufacturing partner. In fact, the best product designers will have hands-on manufacturing experience and will therefore a) design products with the knowledge of how they can be cost-effectively built on the factory floor, and b) clearly convey information about the project to the chosen manufacturer.

What are the benefits of using a professional product designer?

There are several reasons to hire a product designer, from ensuring compliance with regulations to producing a more appealing and marketable end product.

The main advantages of using a product designer are:

- Get fresh ideas from another source

- Save time for other matters

- Achieve improved aesthetic design

- Achieve improved functionality and ergonomics

- Validate design and reduce risk

- Tailor product to manufacturing processes to reduce chances of manufacturing defects

- Achieve compliance and meet regulatory requirements

- Create smooth pathway to production

Some very best place to find product design companies

Besides looking up product design company from search engine, here are some of the best product design communicate media such as Core77 and Yanko Design where you can find out verified product design suppliers with their case studies.

Who are the best product design companies?

When choosing a product design company to work with, you may want to work with a local company to make collaboration easier. However, work can also be done remotely via online meetings and data sharing.

There are tens of thousands of reputable design companies around the world; some popular names include:

USA: RKS (California), Herman Miller (Michigan), Designworks (California), IDEO (California), Smart Design (New York)

UK: Seymourpowell, Pentagram, Foster + Partners, Design Bridge, Cambridge Design Technology

EU: CBA (France), Rudolph Schelling Webermann (Germany), Struppler (Germany), Alegre Design (Spain)

Australia: Design + Industry, Evie Group, Frost*collective

China: BonaudiDesign (Shanghai), Kokaistudios (Shanghai), Miio Studio (Shenzhen), Design2Gather (Shanghai)

Is it safe to work with third-party product designers?

Some entrepreneurs and startups may be hesitant to work with third-party product designers and product developers, fearing that the security of their intellectual property could be compromised in some way.

However, any legal concerns can be mitigated with the use of a non-disclosure agreement (NDA), which legally prevents the designer from sharing your concept with other parties.

In most cases, product designers can carry out their tasks for your project in house, without having to show your design to anyone else.

In fact, working with an experienced product designer can actually boost your ability to protect your IP and plan a strategy to beat your competitors. Some product designers will offer a full product concept investigation, which encompasses patent analysis, competitor analysis, and reports on the state of the market.