For those who dabble in manufacturing or prototyping, terms “jig” and “fixture” appear frequently, especially when talking about machining — a subtractive manufacturing process for plastic and metal parts. But what are jigs and fixtures, what are jigs and fixtures used for, and why are jigs and fixtures so important?

Although often grouped together, these two tools play different functions in the manufacturing process and are often used with different pieces of manufacturing equipment. They both help to produce more accurate and repeatable parts, and both can be made using a few different manufacturing techniques, but jigs and fixtures remain fundamentally different.

This article will serve as an introduction for anyone who needs jigs and fixtures explained. It will look at the main differences between jigs and fixtures, as well as their main applications and how they can be made.

What are jigs and fixtures?

Before getting into the specific attributes of jigs and fixtures, we should take a step back and ask the broader question of what type of object jigs and fixtures are.

We can think of both of these items as tools or pieces of tooling: implements used in the fabrication of new parts that are distinct from the manufacturing machinery (e.g. CNC machine, 3D printer) and the parts being made. (Other examples of tooling include material forming devices like molds and dies, and cutting tools such as drill bits.)

More specifically, both jigs and fixtures — but especially fixtures — can be considered workholding devices: items used to keep a workpiece (the in-progress part being made) stable and secure during manufacturing.

What is a jig?

We’ll start our explanation of jigs and fixtures with jigs. In short, a jig is a tool used to control or guide the movement of a cutting tool such as a drill (and sometimes to simultaneously hold the workpiece).

So why do manufacturers use jigs? By introducing a tool that precisely guides the movement of a cutting tool, a manufacturer can, for example, guarantee repeatability: ensuring the same cut is made in exactly the same place on several duplicates of a part. The same jig can be used over and over, resulting in the same outcome with each use.

Since their purpose is primarily to guide and direct cutting tools, jigs are most commonly used for manual work, i.e. manual machining and drilling. (CNC machines are less dependent on jigs, since they are designed to provide micron-level precision without assistance; their cutting tools are “guided” by computer instructions.)

Types of jig:

- Template jig: A simple jig that can be fitted onto the workpiece, it has holes through which a cutting tool (e.g. drill) can be guided.

- Plate jig: Similar to a template jig but with drill bushes instead of just holes.

- Angle-plate jig: Used to prop up the workpiece at an angle to facilitate the drilling of e.g. diagonal holes.

- Leaf jig: A jig with a hinged leaf that can be swung open and closed for faster loading or unloading.

- Diameter jig: Used to enable the drilling of rounded workpieces that cannot easily be secured in other types of jig.

What is a fixture?

Fixtures have a few features in common with jigs, but their purpose is essentially different. The sole function of a fixture is to keep a workpiece stable and secure during manufacturing; a fixture is therefore a workholding device in the truest sense.

Fixtures can perform several functions. By keeping a workpiece fully secure, they ensure accuracy and repeatability. They can also be adjusted to hold a workpiece at a specific angle, allowing for cutting operations in a range of directions. Fixtures also minimize errors and guarantee the safety of workers by preventing the workpiece from being accidentally flung from the work table. Like jigs, fixtures are often used in machining operations.

You are likely to see fixtures in use on CNC machining centers and other automated manufacturing equipment. CNC machines can direct their cutting tools without the use of jigs, but they will not work properly if the workpiece cannot be kept secure.

While jigs are typically held in place with fasteners or even held manually by the machine operator, fixtures have a variety of clamping options, including hydraulic, pneumatic, and vacuum systems for applying the requisite force.

Types of fixture:

- Turning fixture: Typically mounted on the machine spindle or a face plate, turning fixtures are useful for more complex lathe-made parts.

- Milling fixture: Typically secured to the work table with fasteners, these fixtures enable a variety of milling operations.

- Drilling fixture: Comprising hole and bushing, drilling fixtures are sometimes used in place of (or in addition to) jigs.

- Grinding fixture: Used to support a workpiece during grinding operations.

The difference between jigs and fixtures

Are jigs and fixtures the same thing? No, they are not: although both are types of tooling used in manufacturing, and although they share some of the same traits, they are distinct objects.

The main difference between a jig and a fixture is that a jig plays some role in controlling the position or movement of another tool, generally a cutting tool, while a fixture is concerned with the position of the workpiece (the piece of material being turned into a new part).

A jig sometimes performs two roles, controlling the position of both the workpiece and another tool, while a fixture performs one.

In practice, this means that jigs and fixtures are often used in different situations. Applications of jigs are often found in manual work, where humans need help to move a cutting tool to the exact point required (to ensure that a drill makes a hole in exactly the right spot, for example). On the other hand, applications of fixtures are found in both manual and automated work: cutting tools do not always need guidance, but a workpiece always needs to be secured to ensure precision and safety.

Other differences between jigs and fixture include:

- Jigs are often fairly lightweight, while fixtures must be heavy enough to provide stability

- Jigs can be held in place manually, while fixtures are mechanically secured to the table

- Jigs may require more intricate design, while fixtures are typically more straightforward

Advantages of jigs and fixtures

The use of jigs and fixtures during manufacturing can lead to significant benefits in terms of production and part quality. The main benefits include:

- Increased production rate

- Eliminates need for manual measurement and alignment

- Consistency and accuracy across multiple parts

- Reduced dependence on manual skill of machinist

- Reduced dependence on post-manufacturing quality control measures

- Improved safety for workers

- Allows machinist to adjust feeds and speeds for faster production

Components of jigs and fixtures

Jigs and fixtures may look like simple tools, but they are typically made up of several sections. These sections are:

Body: The bulk of a jig or fixture is its body, typically a solid piece of metal strong enough to withstand significant forces.

Clamping devices: The clamping devices of a jig or fixture are used to hold a workpiece secure and resist cutting forces.

Locating devices: Typically made from hardened steel, locating devices such as pins are used to put the jig or fixture in the right place.

Bushings: Typically made of tool steel, bushings are used in some jigs to guide the machine tool in its operation.

How to make jigs and fixtures

There are a few different options when it comes to manufacturing jigs and fixtures. While CNC machining has been the dominant method for some time, 3D printing is now a viable alternative.

Although jig and fixture materials are typically metal — more specifically steels such carbon steels, mild steels, and die steels — it is also viable to make plastic jigs and fixtures if low clamping forces are required. Nylon is a common plastic used in jig and fixture production.

Design considerations

- Jigs and fixtures should be foolproof to prevent misplacement

- Cost of production should be less than predicted cost savings

- Location points should be clear (and ideally adjustable) to minimize idle time

- Clamping arrangements should not be complicated

- Jigs and fixtures should be robust enough for use but lightweight enough for easy handling

- Tools should have ample clearance

- There must be adequate space for chip clearance

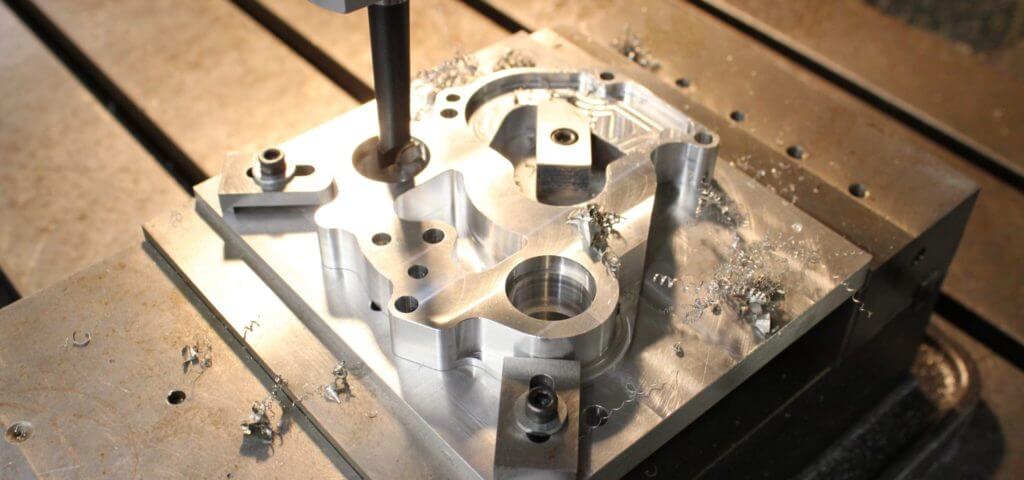

CNC machining jigs and fixtures

Best for: Robust steel jigs and fixtures, simple geometries

At present, CNC machining is the dominant method for making jigs and fixtures. This is because CNC machining is cost-efficient for small quantities (and jigs and fixtures tend to be custom built for specific parts).

CNC machined jigs and fixtures are ideal when the jigs and fixtures need to be robust but not especially complex in terms of their geometry. Most steel jigs and fixtures are CNC machined.

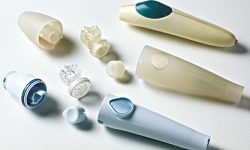

3D printing jigs and fixtures

Best for: Rapid and plastic jigs and fixtures, complex geometries

3D printing or additive manufacturing is an alternative to CNC machining for rapidly making jigs and fixtures. Like CNC machines, 3D printers are efficient at fabricating one-off items.

3D printed jigs and fixtures can have more complex geometries than machined ones, and 3D printing may be a more affordable option for plastic jigs and fixtures (via SLS, for example). In most cases, however, machined jigs and fixtures have superior strength.