Flash or flashing is one of the most common problems associated with injection molding, the most widely used manufacturing process for plastic parts. Injection molding flash is when a line of excess material builds up on the outside of a molded part, typically after leaking through the parting line of the mold. A small amount […]

Maintaining the condition of the putting green is essential to a successful round of golf. Custom golf divot tools, made using 3D printing of CNC machining, are a great way to improve your putting game while personalizing the golfing experience. Few sports are as dependent on the condition of the playing field as golf. In […]

Digital 3D files have changed the way engineers work with manufacturers. Engineers can now design a part using CAD software, send the digital file to a manufacturer, and have the manufacturer make the part directly from the file using digital manufacturing techniques like CNC machining. But although digital files have made manufacturing faster and simpler, […]

Plastic fabrication is essential to most industries. From polystyrene food packaging to industrial components made from engineering-grade PEEK, plastic fabrication contributes hugely to life as we know it. Without the ability to make plastic parts, we would need to develop radically new systems of production. But plastic fabrication comprises many different methods. Injection molding, plastic […]

Galvanization is a process for adding a coating of zinc to the surface of steel or iron. Since the zinc acts as a sacrificial coating, it protects the steel or iron underneath and can therefore extend the lifespan of metal parts. But galvanization is a complex process that can be carried out in several ways. […]

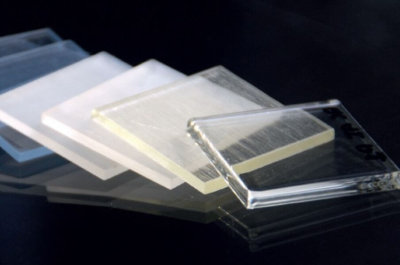

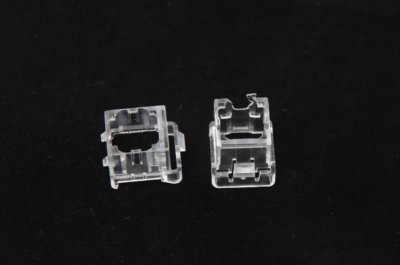

Clear parts and prototypes have a huge variety of applications. Fortunately, they’re also fairly easy to make, with a wide range of materials and prototyping technologies at your disposal. This article goes over the basics of transparent and translucent parts: why you might need them, what materials you can use, which manufacturing technologies are available, […]

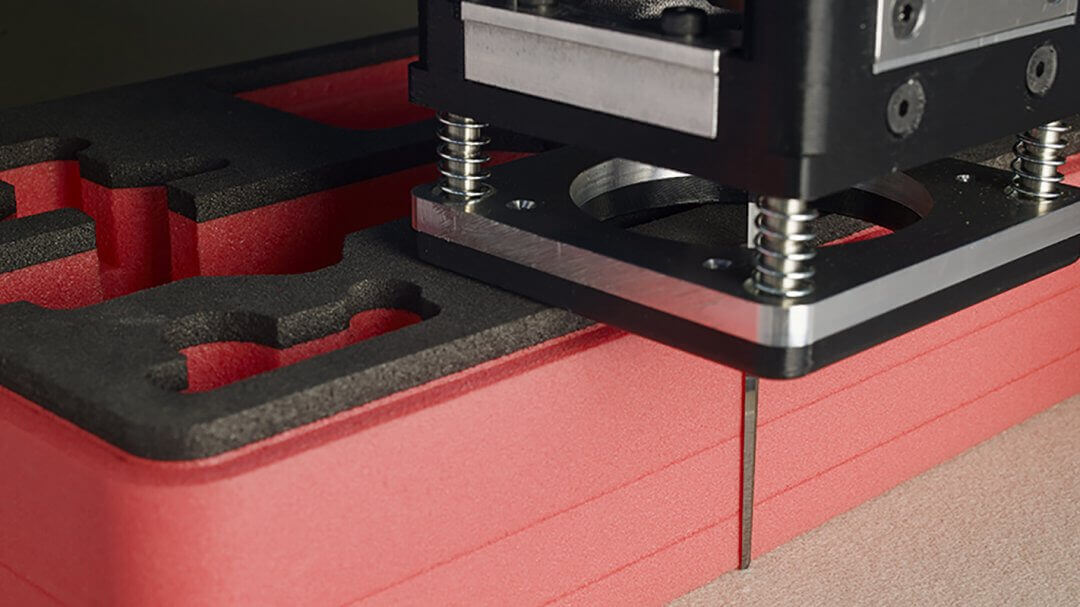

Sheet metal fabrication, the practice of manipulating flat pieces of metal into new shapes, is a practical and low-cost solution for making parts like brackets, enclosures, and kitchen equipment. It is one of the most efficient ways to make very large, simple products that don’t have highly detailed features. However, engineering successful sheet metal parts […]

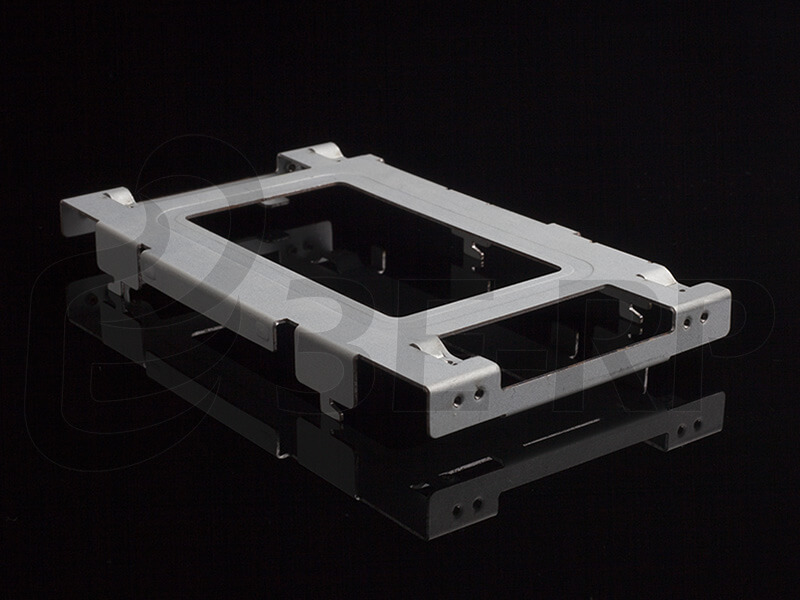

Why do use Injection Molding? Injection Molding is typically a manufacturing process for making a large number volume of products and it is hugely used in mass-production processes. It can able to produce the same products thousands or even millions of times in series. There are different benefits customers can reap from this process. Alongside […]

Technical drawings (and the process of drafting) are a means of conveying information between engineers and manufacturers. Technical drawings usually complement digital CAD files, providing extra information that can’t easily be conveyed by a part’s shape alone. In the world of prototyping and manufacturing, we typically deal with a certain subtype of technical drawings known […]

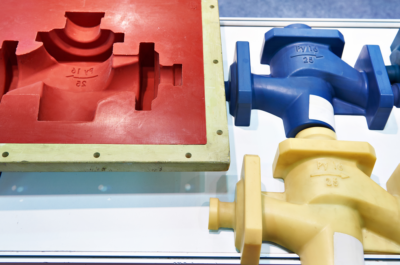

Rapid Injection Molding is precisely defining its name as this process ensures speed and quality during manufacturing. However, it is one of the most convenient, popular, and cost-effective manufacturing processes for critical design during molding procedure and widely appreciated by various industries. All you just need to find out the best source that would meet […]

How Does Plastic Injection Molding Work? Typically the Plastic Injection Molding process involves aluminum mold that does not require cooling channels. A professional manufacturer can efficiently produce high-quality parts as per clients’ concerns. In this process, the hot melted resin shot into the mold cavity through the gates and hence converted into molded parts. Once […]

Plastic Injection Mold Making is a specialized process that can produce parts precisely and accurately. This process is highly efficient, simple, and cost-effective. Most of the companies are using this technique to meet their clients’ demand in the market. Plastic injection molding has been known as a dependable, deep-rooted manufacturing procedure for many years. All […]

What is Plastic injection molding? In the Plastic injection molding process, usually molten plastic injected into a mold to produce exceptional quality of plastic parts plates, plaques, signs, and product branding elements. After injecting molten plastic, it gets cools and solidifies to yield a wide range of plastic parts from the Plastic Injection Mold. When […]

In certain conditions, even the strongest metal parts can suffer from corrosion, which occurs when metals react with their environment. Corrosion turns the surface of the metal part into a metal oxide, hydroxide, or sulfide. Any metal can suffer from some degree of corrosion, though some react under different circumstances than others. Importantly though, corrosion […]

Metal fabrication projects are a delicate process due to a number of factors, but the most daunting is building the actual practical version of the design and bringing it to life. Even if you’re outsourcing to a 3rd party fabrication service provider with a lot of experience, things can go wrong. Getting the most of […]

Injection molding is a manufacturing process that produces strong and durable parts in giant quantities. It is one of the most cost-effective manufacturing processes and works with a wide array of plastic materials, including thermoplastics and thermosets. You can even mold plastic components over other materials using overmolding and insert molding. Sometimes, however, typical injection […]

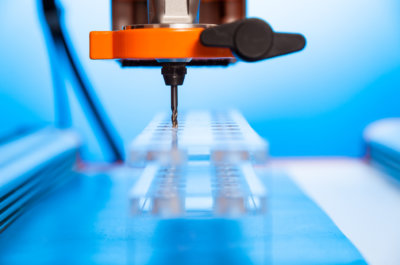

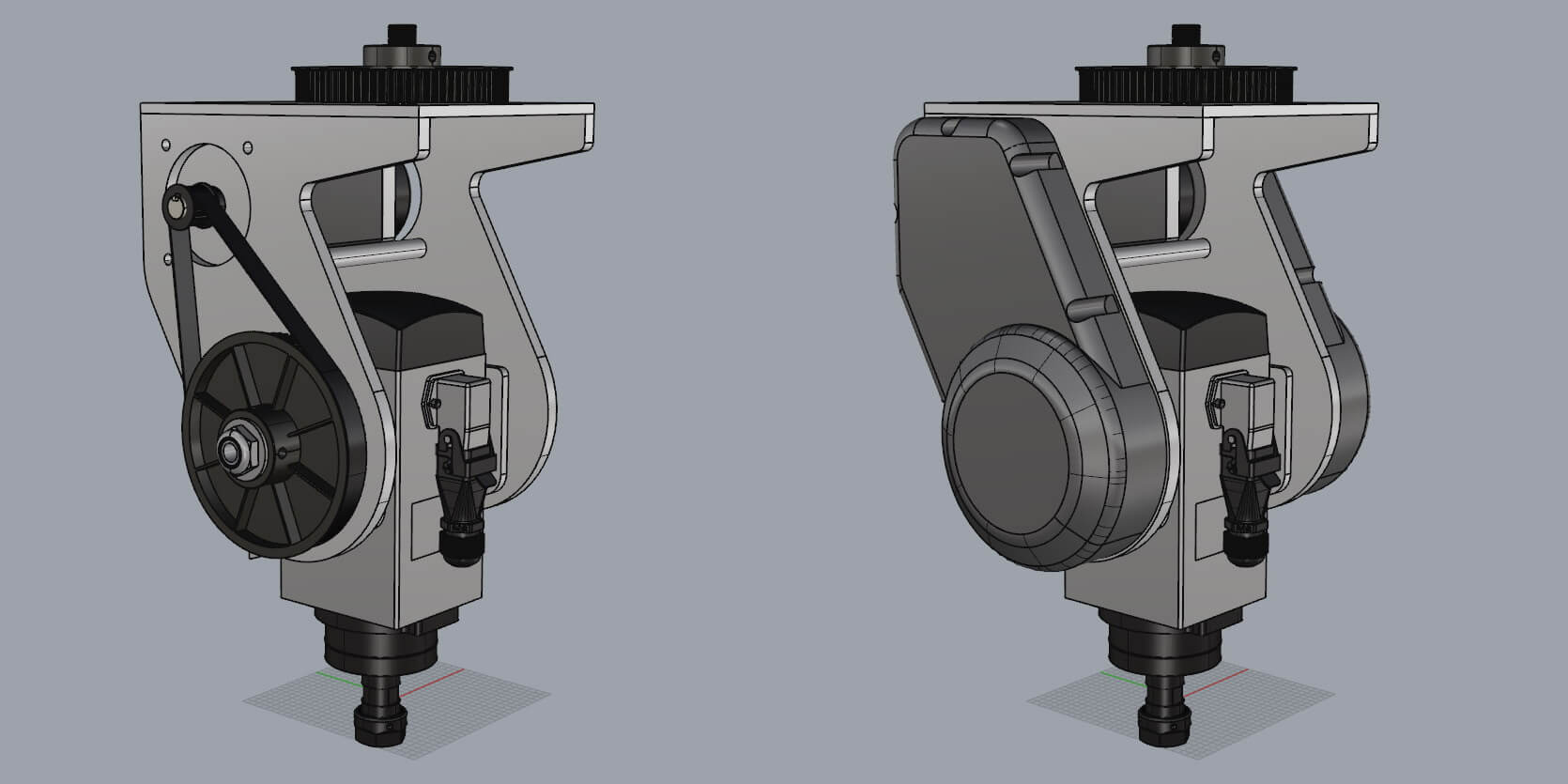

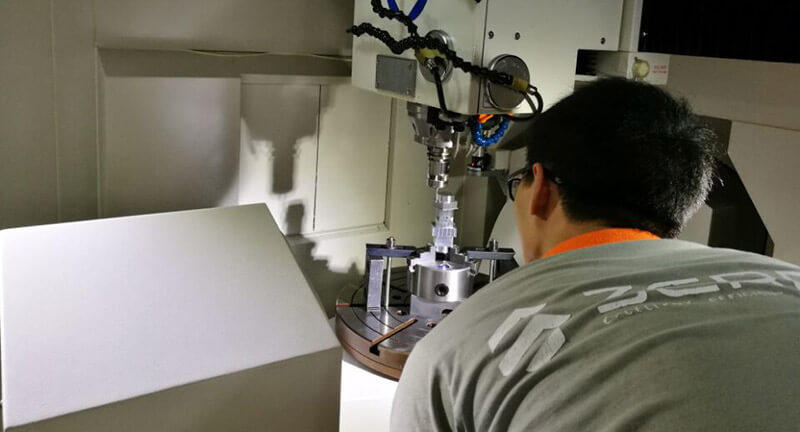

With an abundance of manufacturing technologies making the rounds these days, there are so many to choose from. While all of them have their unique niches and those specifics areas where they excel above others, CNC machining is proving to be the most popular industrial option among the pack. Here are just some of the […]

Pretty much every product we buy comes in some form of casing or package that needs its own set of manufacturing processes. Over the years, these packages and cases require consistent designs, often produced with the fit and geometry of the product in mind. Today, most packaging equipment is automated for efficiency and faster production […]

It is a process in which the liquefied metal is displaced into a cast, which has a hollow enclosed space in a desired form and then allows the metal to cool off and inure. The hollow cavity is denoted as cast and it gives the desired form that resembles the part being manufactured. Now the […]

As one of the most prominent technologies in the world, CNC machining is big business. Overall, the industry has seen growth all over the world (see our article on the industry outlook for CNC), but there are finer details worth examining for regional trends. Globally speaking, the largest machine tool consumers are China, the US, […]