Plastic fabrication is essential to most industries. From polystyrene food packaging to industrial components made from engineering-grade PEEK, plastic fabrication contributes hugely to life as we know it. Without the ability to make plastic parts, we would need to develop radically new systems of production.

But plastic fabrication comprises many different methods. Injection molding, plastic extrusion, and FDM 3D printing are all plastic fabrication methods, and there are many more besides. These different plastic fabrication methods suit different plastic parts, and choosing between them isn’t always straightforward. Budget, part design, and material are just some of the factors that go into choosing a plastic fabrication method.

This article looks at 12 different plastic fabrication methods, explaining their basic processes and why they are useful. For each plastic fabrication method, we will give some examples of how it can be used to make end-use parts.

1. Injection molding

Injection molding is the most common plastic fabrication process. It can process thermoplastic and thermoset polymers.

This fast plastic fabrication method works by heating plastic pellets until they melt, then forcing the molten plastic into a metal mold using a reciprocating screw. The molten material cools down, solidifies, and assumes the shape of the mold cavity. The solid part is then ejected from the mold.

Injection molding is suitable for a huge variety of materials and parts. Parts must have thin and consistent walls but can otherwise assume various shapes and sizes.

Example injection molded parts: disposable food trays, car dashboards, LEGO bricks

2. Blow molding

Blow molding is a plastic molding process that is less widely used than injection molding. It has three distinct variants: extrusion blow molding, injection blow molding, and injection stretch blow molding.

This plastic fabrication processes works using a mold and a molten thermoplastic tube called a parison (instead of fully melted pellets). Pressurized air enters the parison, causing the plastic to expand and touch the internal walls of the mold, eventually assuming the shape of the mold cavity.

Blow molding is suitable for hollow plastic parts like plastic water bottles, with HDPE the most common material.

Example blow molded parts: bottles, drums, fuel tanks

3. Rotational molding

Rotational molding is another plastic molding process — one that uses high temperatures and low pressure to form plastic parts. It works by rotating a mold to move the plastic material around inside.

During the rotational molding process, powdered plastic is placed in a mold, which is heated and rotated about two (or more) axes. This rotation ensures that molten plastic covers the entirety of the inside of the mold and assumes the shape of the cavity.

Advantages of rotational molding include simpler tooling, consistent wall thickness, and strong external corners. But the process can be slow, since the entire mold needs cooling before part ejection.

Example rotational molded parts: bins, storage tanks, toys

4. Vacuum casting

Vacuum casting is a plastic fabrication process usually employed for small batches of colorful prototypes. It uses silicone molds to make urethane plastic parts.

During this plastic fabrication process, the operator pours urethane casting resin into a silicone mold; a vacuum then removes air pockets and bubbles, resulting in an exceptionally smooth finished part. The urethane parts are then cured in an oven.

Vacuum casting is a popular plastic fabrication process for partially transparent parts like prototype display cases.

Example vacuum cast parts: electronics cases and covers, various display prototypes

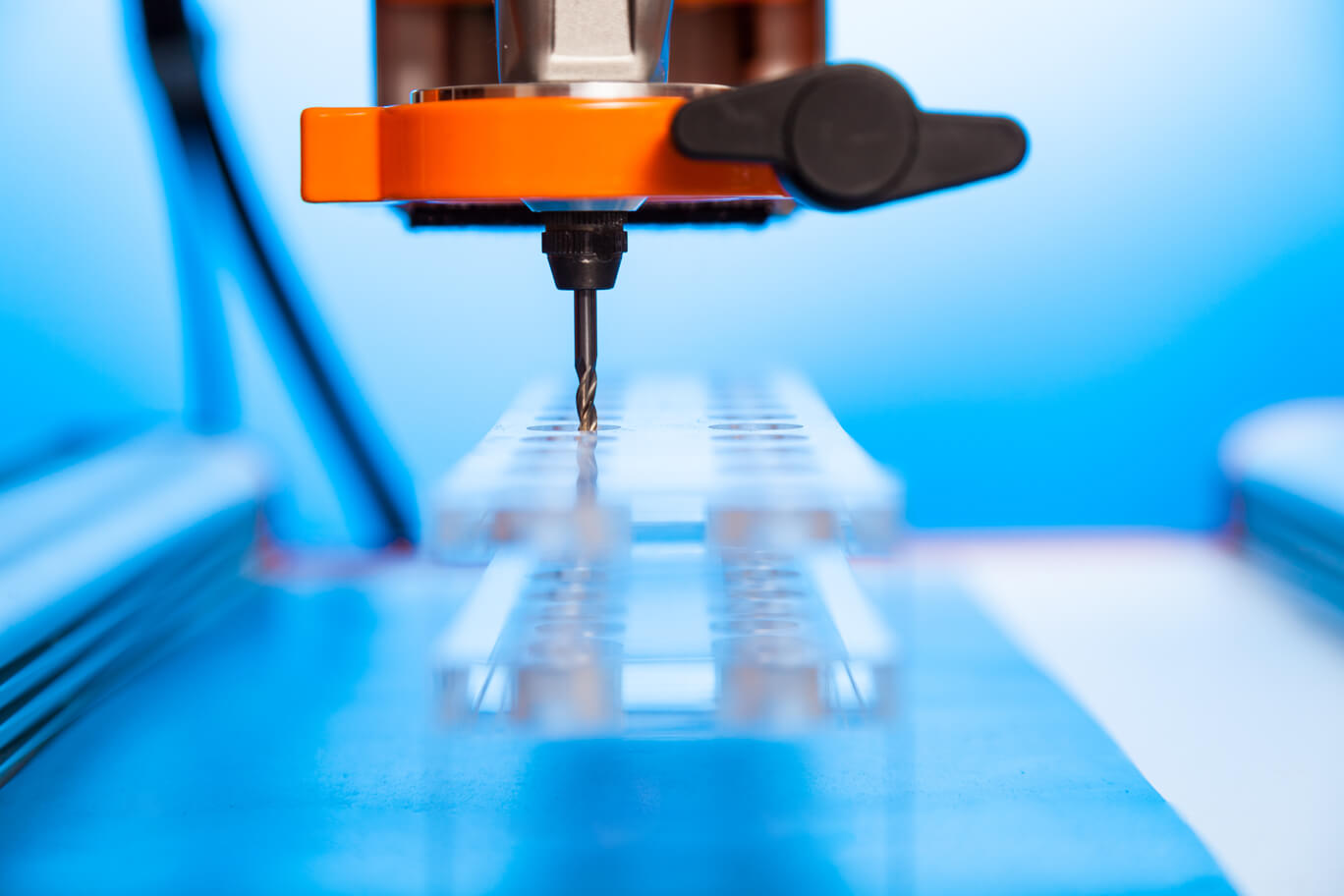

5. Plastic machining

Plastic CNC machining is a very popular plastic fabrication process. It encompasses CNC milling, CNC turning, and other related processes.

Although different machines work in different ways, plastic machining generally entails cutting away sections from a plastic workpiece using either manual or computer-controlled cutting tools. Machining is highly accurate, works with a range of plastics, and is better than molding for making thick-walled parts.

Plastic machining is also useful for adding details for parts made using other techniques like extrusion.

Example machined parts: various industrial parts, jigs and fixtures, automobile lighting

6. Fused deposition modeling

Fused deposition modeling (FDM) is the most common 3D printing process for plastic fabrication. It works with common thermoplastics like ABS and PLA, as well as advanced materials like PEEK.

FDM works by heating up extruded thermoplastic filament, then depositing it in precise shapes from a moving nozzle (attached to a printhead) according to computer instructions. 2D slices of the part are printed layer by layer until the complete 3D object is built.

In small quantities, FDM is very fast and cost-effective and can produce a wide range of shapes, including those with complex internal geometries. However, it does not produce especially strong parts.

Example FDM parts: various prototypes, spare parts and repairs, composite industrial parts

7. Stereolithography

Stereolithography (SLA) is a different form of plastic 3D printing that works with photopolymeric resins instead of thermoplastic polymers.

It works by selectively curing photopolymeric resins using a light source such as a laser. (Digital light processing, a related technology, used a projector instead.) Parts are printed layer by layer as the print bed moves through the resin vat.

SLA produces brittle but exceptionally smooth parts, which can also be transparent. It is often used for prototyping but also has applications in dentistry in jewelry.

Example SLA parts: display prototypes, dental aligners, jewelry patterns for casting

8. Selective laser sintering

Selective laser sintering (SLS) is a plastic fabrication process and another form of 3D printing. It is principally used to make nylon parts.

SLS is a powder bed fusion process. It works by using a laser to selectively sinter 2D shapes in plastic powder, layer by layer, building a complete plastic part. It is broadly similar to the metal additive manufacturing process of selective laser melting (SLM). An advantage over other plastic 3D printing methods is that it does not require support structures.

More so than FDM or SLA, SLS is considered an industrial additive manufacturing process and is popular in the automotive industry.

Example SLS parts: tooling, automotive hardware, electrical connectors

9. Plastic extrusion

Not to be confused with extrusion 3D printing, plastic extrusion is the process of forcing plastic through a die to make an elongated plastic part with a consistent profile.

This high-volume plastic fabrication process works by heating plastic in a barrel, then forcing it — using a reciprocating screw — into a die, giving it its final shape with a continuous profile. The resulting plastic extrusion hardens as it cools down.

Common plastic extrusion materials include polyethylene, polypropylene, acetal, and nylon. The process also has variants like blown film extrusion and tubing extrusion.

Example extruded parts: pipes, tubing, window frames

10. Plastic pultrusion

Plastic pultrusion is a variant of plastic extrusion in which the material is pulled through a die rather than pushed.

The plastic fabrication technique of pultrusion is suited to fiber-reinforced plastics. During the process, a roll of reinforced fibers is pulled through a tank of plastic resin, which impregnates the fibers, and then through a heated die, giving the fiber-reinforced resin its custom profile.

Several plastic resins are suitable for pultrusion, including polyester, polyurethane, and epoxy. Glass fibers are the most common reinforcing material.

Example pultruded parts: stiffening bars, ski poles, various reinforcing structural parts

11. Plastic welding

Welding is mostly associated with metals, but plastic welding is a useful plastic fabrication process for joining thermoplastic components not suitable for gluing or other assembly methods.

The plastic welding process has a huge number of variants, including hot gas welding, speed tip welding, and contact welding. The majority of variants involve preparing the surface of the plastic, applying heat and pressure, then cooling.

The various plastic welding methods can be classified as thermal, mechanical, or electromagnetical.

Example welded parts: housings, cellphone parts, medical devices

12. Thermoforming

Thermoforming is a type of plastic fabrication that resembles molding but which uses gently heated plastic sheet instead of fully molten plastic.

The plastic fabrication method technique requires an oven and a mold. During the process, the plastic sheet is heated until pliable; it is then stretched over a mold — typically using a vacuum — before being trimmed and cooled.

Thermoforming is fairly versatile, as it can be carried out on both a small scale or for mass production.

Example thermoformed parts: blister packs, plastic cups, lids

3ERP is a plastic fabrication expert offering prototyping and low-volume production using a number of plastic fabrication technologies. Get a free quote today.