Cutting Dream Contest Award is hosted by Mori Seiki Co., Ltd. The Cutting Dream Contest is open to companies, schools and research institutions engaged in machining in Japan. It is intended to promote the exchange of information on machining technologies and techniques. These CNC experts show off their capability as well as their imagination by creating crazy parts. They try to hit the limited of the machines, tools and materials. And eventually, they proved CNC machining can do much more than we expected. Be sure to look at the size!

JACKET

Material:Aluminum 5052

Machine type:horizontal milling center

Summary: To simulate a soft coat in metal is a brilliant idea. It also shows the capability of CNC machining.

3D Ant

Material:HPM38

Machine type:NV4000DCG

Summary: It is not only the height of modeling technology and processing technology, but also the experience of advanced die finishing technology. Each part created in 12 points refeels the accuracy of the parts at assembly time.

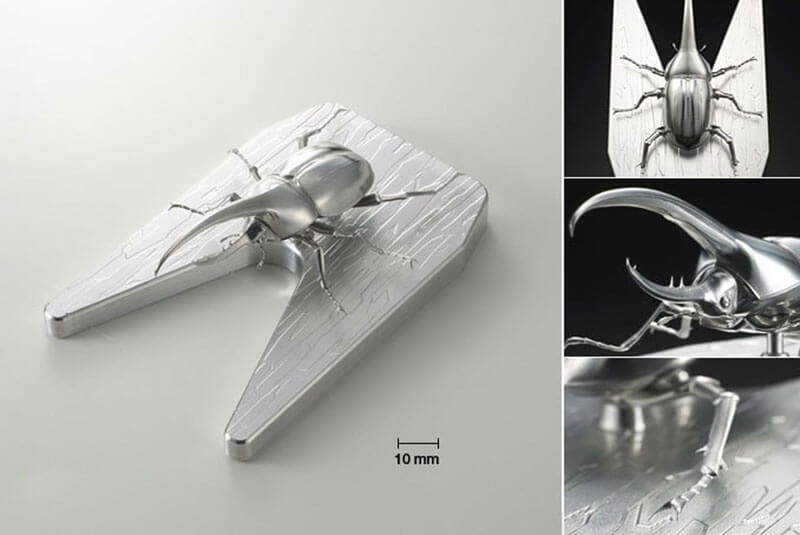

Beatles

Material: A5052

Machinery Type: VS40

Comments: Even the tiny tiptoe or tactile feel can be truly processed, a highly accomplished work, and the beauty of realism and its overwhelming sense of existence are fully manifested.

Fruits

Material: Aluminium, Brass, Copper

Machinery Type: 5 Axis CNC machine

Comments: This outstanding work refers to the creative ability to combine different material sculptures, showing different textures, and can make people deeply aware of their beauty, presence, and expressiveness.

Sailboat

Material: A5052

Machinery Type: Vertical Machining Centre

Comments: From the thinnest 0.2mm sail, then the wind direction meter to the propeller, a total of 73 parts are cut out and processed, fully showing the detail of the work and its original shape.

Great machines = great parts? You also need skillful people with great attitude, who determine to make high quality parts. At 3ERP, we invest high quality machines and the latest manufacturing technology. In the meantime, we hire well educated people who will take care of quality for every single part, and willing to take challenges. Lern more about our CNC machining services and review the cool projects we have done before.