Why do use Injection Molding?

Injection Molding is typically a manufacturing process for making a large number volume of products and it is hugely used in mass-production processes. It can able to produce the same products thousands or even millions of times in series.

There are different benefits customers can reap from this process. Alongside the mass-production ability, it is a cost-effective process. You will pay a low price per unit during injection molded manufacturing. Even this price will low as more parts are produced.

This process makes low scrap rates as compared with CNC machining which cut away considerable percentages of an original plastic sheet.

This molding procedure is repeatable that ensures that the second part you create is going to be practically indistinguishable from the first one. This is however the best part of this manufacturing process while producing parts in a high volume.

Injection Molding in China incorporates 3 major stages that are discussed below-

Product Design- this is the first and foremost section of this procedure that prevents expensive mistakes later on. When we talk about designing a part, it considers different aspects such as function, aesthetics, manufacturability, assembly, etc. Hence, a professional manufacturing company should take it seriously and execute it precisely by using their creativity to meet a satisfactory level. In most cases, it involves computer-aided design (CAD) software that offers accurate prototyping and quicker iterations.

3ERP can brainstorm, design, and improve upon various solutions to meet the needs of a specific project. Backed by a wealth of experience in making designed solutions to intricate problems, we can provide the best deal to our clients.

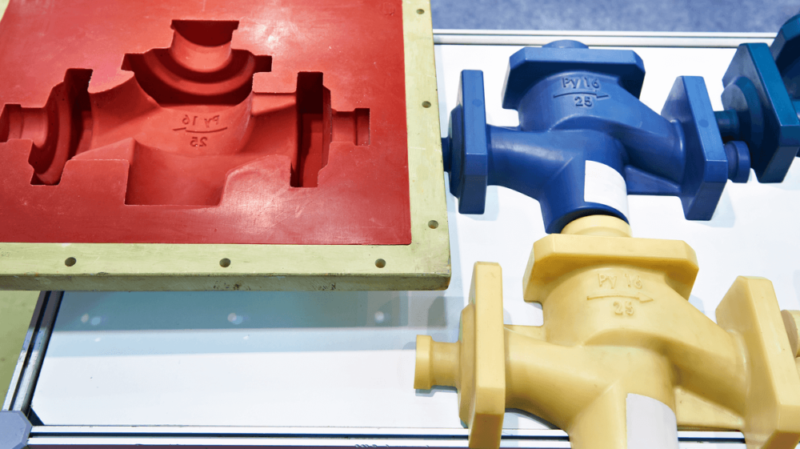

Mold Design- Mold allows the production of the exact design of the part. So the molds should be designed for injection mold manufacturing as per the client specifications. These molds are usually made from Hardened steel, Pre-Hardened steel, Aluminum, Beryllium-Copper alloy, etc.

Remember that the precise design of mold prevents during this manufacturing process. An improper design of mold can create various issues. When the draft of mold is not properly done, it causes ejection problems. Sometimes, placing inappropriate gates (openings in a mold that enable thermostat or thermoplastic material to inject in) can create issues.

The process of Injection Molding in China- 4 Key considerations-

Every manufacturing process needs to be performed well by a team. Even the customers also need to consider such things before endeavoring. When it comes to the injection molding process, customers should focus on the following tips-

Budget- It is one of the most crucial points you need to consider as this molding process requires investment. Make sure you are aware of all the investment needs.

Numbers of parts- You need to be exact on the number of products you want to produce. This will determine your initial investment. Although it is a cost-effective process to produce your parts, you need to know about the prices of design, testing, production, assembly, marketing, distribution, etc.

Designing- You should decide on the part design with simple geometry. In the initial part, you can also reduce the number of parts to be produced. The tool involved in this process has to be precisely designed that prevents any defects during production.

Conclusion- This manufacturing process is the most convenient option for making parts in a huge number. It also helps for finalized prototypes used for product testing. All you just need to hand over your projects to a reliable and highly professional company that can handle your requirements effectively.

3ERP is a leading manufacturing team that provides industry-standard Injection Molding in China at the best pricing range. Contact us for more information.