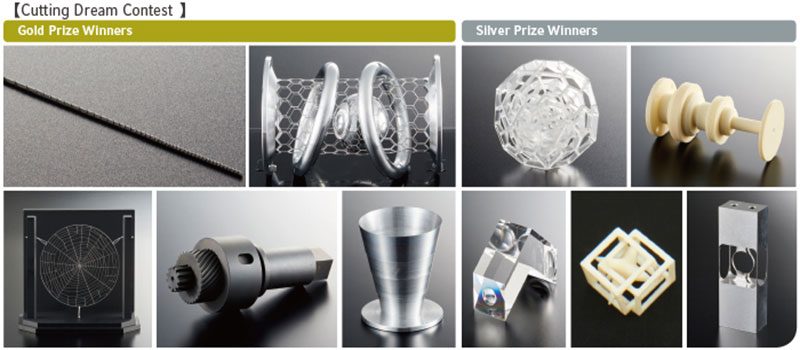

Mind blowing CNC parts (ONE)

Cutting Dream Contest Award is hosted by Mori Seiki Co., Ltd. The Cutting Dream Contest is open to companies, schools and research institutions engaged in machining in Japan. It is intended to promote the exchange of information on machining technologies and techniques. These CNC experts show off their capability as well as their imagination by creating crazy parts. They try to hit the limited of the machines, tools and materials. And eventually, they proved CNC machining can do much more than we expected.

Please take this opportunity to take a look at the works produced with skillful techniques and unique ideas.

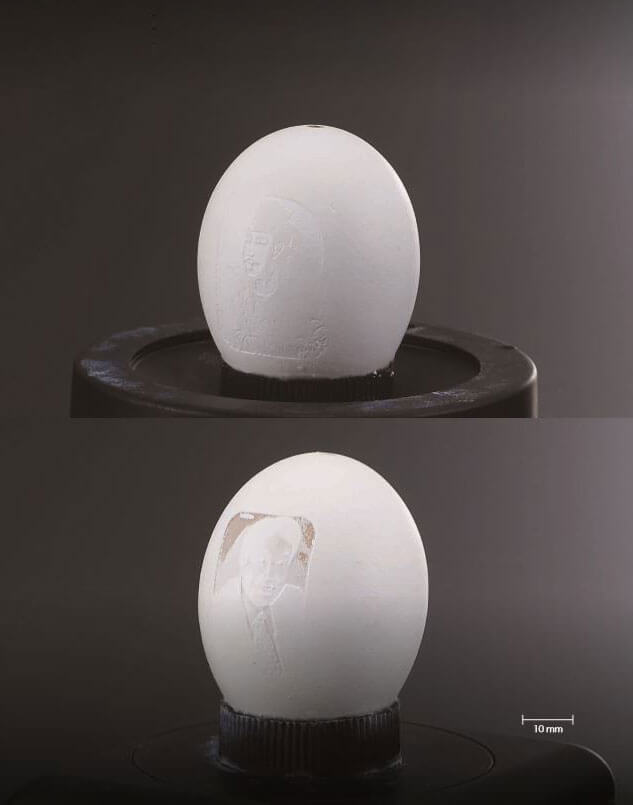

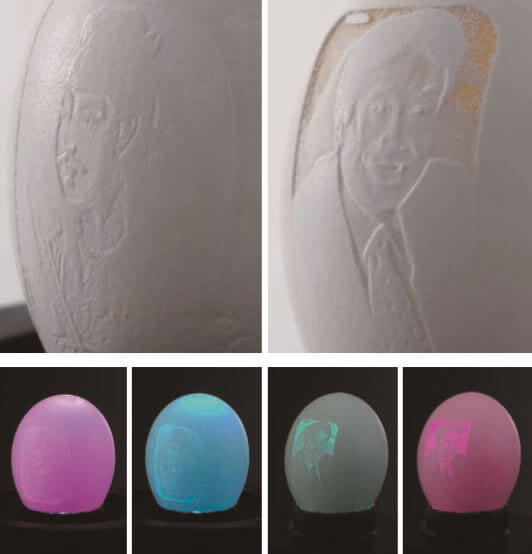

Egg Shell Art

Material:Egg Shell

Machinery :NVD4000 DCG

Processing time: 140 Minutes

PEEK Machined tooth brush

Material:PEEK(high temperature resistance plastic)

Machine type :NT4200 DCG

Remarks: To milling the brush in one piece is a super challenge due to the φ0.3mm×12mm brushes. The engineers have to sort out deformation, vibration, cracking and burrs.

Mini helicopter

Material: A5052

Machinery: Vertical machining center

Comments: The mini helicopters are assembled from three parts. The referent next to the helicopter is a grain of rice.

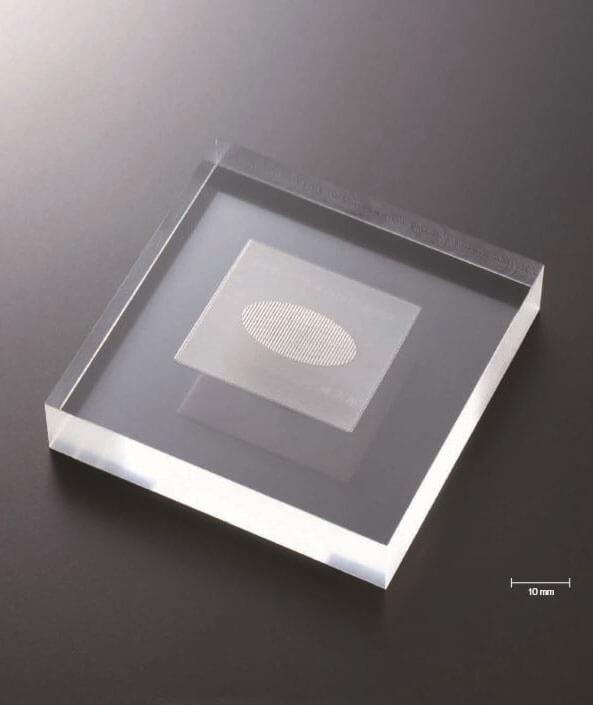

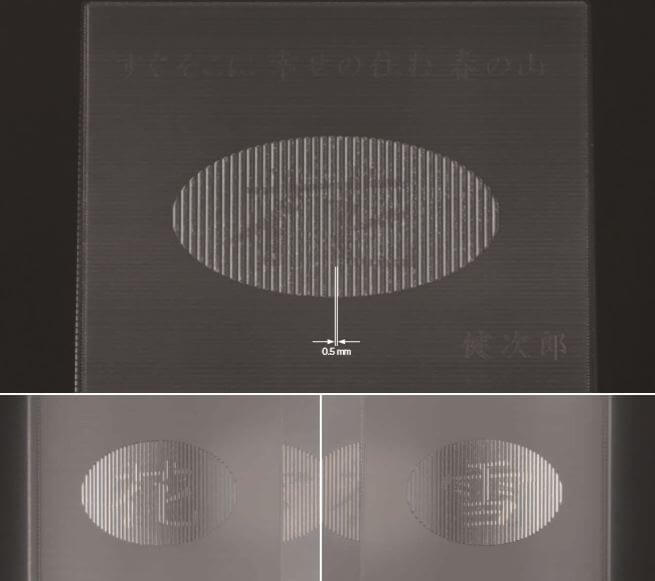

Characters on Acrylic plate

Material: Acrylic

Processing machine: NV 5000

Comments: The word "Snow" "Flower" stand out by cutting the V groove in the ellipse.

Ant

Material: A5052

Machinery: NV4000 DCG

Processing time:10 hours

Comments: The model was well-processed throughout each detail, the fitter worked perfectly, the degree of completion of the form was high.

Nozzle

Material: A6061 T6

Machinery :MT-250/1000

Comments: The are three challenges: φ0.5 mm cutting in the front end, φ0.2 mm through the central hole and 0.2 mm wall thickness during the process.

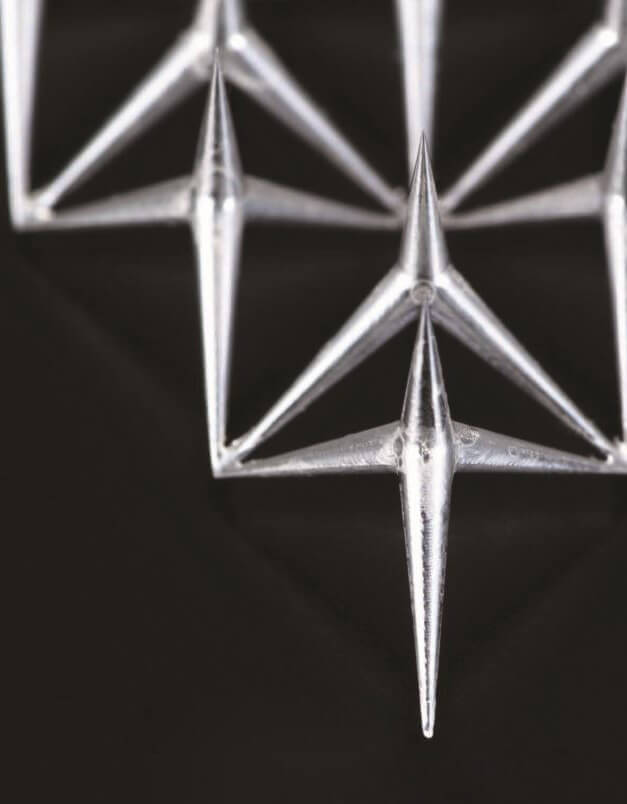

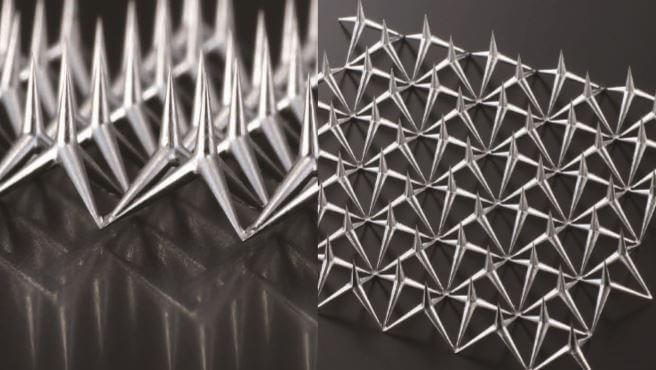

Sharp Art

Material: A7075

Machinery: Vertical machining center

Comments: The challenging is how to make the uneven shape to be processed by high-speed machining center and CAD/CAM.

We will be posting more winning workpieces in the next blogs. 3ERP provides cutting-edge CNC Machining Services , if you are curious how these workpieces be made, please read our latest blog “how to make precise parts & mold cavities”.