Whether your prototype is for user testing or investor pitches, injecting a splash of color can turn a half-finished idea into a part that looks ready for the market.

3ERP offers a range of coloring options for prototypes and end-use parts, offering finishing services like painting, tinting and anodizing, as well as color-friendly manufacturing processes like vacuum casting and injection molding.

While not every prototype requires color, 3ERP can offer expert advice on the various ways to add hues and shades to a variety of parts. Contact us for a free quote, and be sure to mention your interest in colored parts.

Think prototypes can’t look great? Think again!

Why create colored prototypes?

While some business will only add color to their mass-manufactured final parts, there are many reasons why one should add color to a prototype.

For starters, prototypes are often seen by people outside of the company creating them. Potential investors, for example, will often need to see a prototype before putting cash into a project. When the prototype looks great, those investors will be more inclined to get on board.

Potential customers may also get the opportunity to see the prototype during user testing. In these cases, a finished-looking prototype will be more attractive to future buyers.

Colored prototypes also provide more immediate benefits. When creating a prototype part that is part of a larger system, adding color that matches the final part will allow businesses to assess how the individual part looks within the larger system and whether the coloration affects performance in any way.

Creating parts from colored material

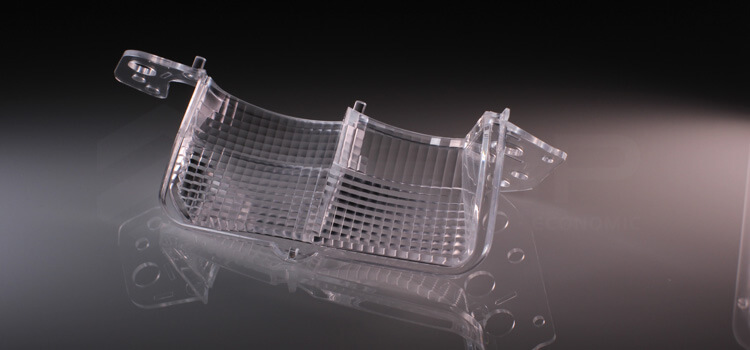

With some processes and materials — usually plastics — it is possible to use colored raw material, allowing parts to be colored without necessarily carrying out coloration at the post-processing stage.

Creating parts from colored material is not the same as adding color to uncolored parts. When creating a metal part using, for example, CNC machining, the part will come out of the machine with the color of its constituent metal. An aluminum part, for example, will have a silver or chrome appearance until it is treated with a coloration process.

Different processes, however, allow for the use of colored raw material, giving parts an intrinsic color that may last longer than color added during post-processing.

3D printing

3D printing is one of the most popular modern prototyping methods, and several additive manufacturing processes can be used to create parts with colored raw material.

There is a huge range of colored filaments available for FDM, the most common 3D printing process and a technique commonly used for non-mechanical prototypes. All popular filament materials, including ABS and PLA, are available in many pigments.

Stereolithography also allows for the creation of colored parts, including partially translucent ones, using colored photosensitive resins. Although rarely used to produce functional parts, stereolithography generally produces a smoother surface finish than FDM.

Vacuum casting

The castable resins used in vacuum casting can be mixed with colorants in the early stages of the vacuum casting process. The process allows for the creation of opaque or translucent/transparent parts, which often look more professional than their low price point would suggest.

While vacuum cast parts can also be painted after manufacture, adding pigment to the resin is usually sufficient for a strong and consistent color.

Injection molding

Although injection molding is more frequently used for manufacturing than for prototyping, the process is also highly amenable to coloration.

The raw material for injection molding comes in pellet form, and these plastic pellets can be mixed with dye pellets before they are melted and injected into a mold.

3ERP offers a variety of material, color and finishing options for injection molded parts, which can be delivered in as little as 15 days.

Adding a colorful finish

3ERP offers a range of surface finishing options for parts made with CNC machining, injection molding and many other processes. These finishing options range from simple processes like sanding to complex procedures like metallization.

Amongst these finishing options are several ways to add color to parts, whether plastic or metal.

Painting

While painting isn’t the most complex way to add color, it’s certainly effective for a wide range of parts. It’s also great for prototypes or parts that only need to be made in small quantities.

3ERP’s painting options include matte, satin, high-gloss, textured and soft-touch coatings.

Tinting

When making parts from plastics like ABS and PMMA, tinting with water-based dyes is another option for adding color. Unlike painting, tinting can be used to add color to translucent parts, creating a whole new range of aesthetic options.

See our recent blog post to find out how we tint PMMA and PC prototypes.

Powder coating

Powder coating can be used to create thick and consistent coatings for a part. Powders come in a range of colors, and are often used to add color and a professional finish to electrical appliances.

Get started

To assess the full range of coloring options for your project, contact 3ERP today.