Plastic Injection Molding

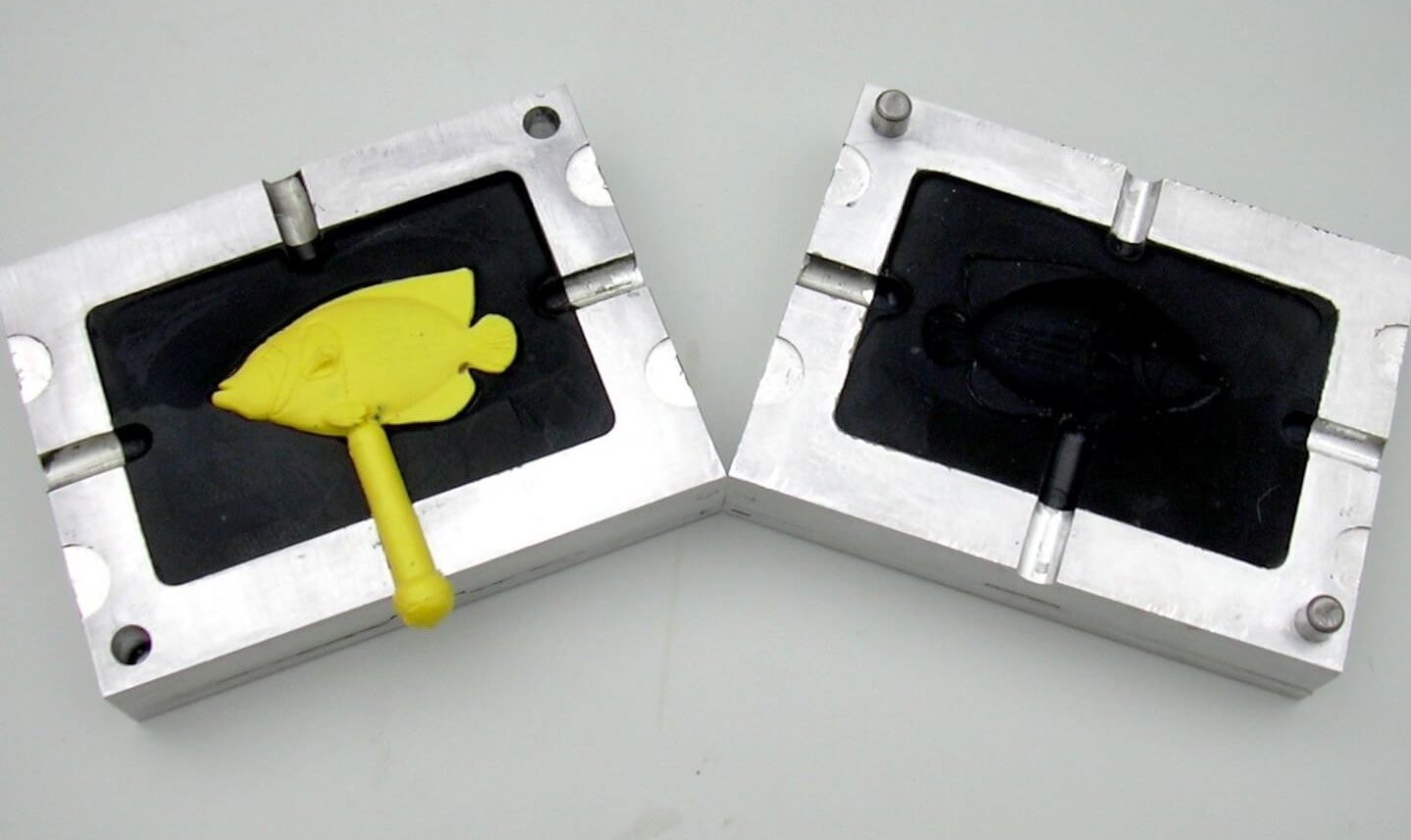

Plastic Injection Molding is a molding process whereby a heat-softened plastic material is injected into a comparatively cool cavity to give an article a required form. It is widely used by many manufacturers to make desired parts from a plastic material. Molten plastic injects into a mold under high pressure to yield parts effectively. When it comes to the molds, they are made by either steel or aluminum mold makers. Most essentially, this process can able to give a variety of precisely designed parts.

The process of Plastic Injection Molding has been gaining popularity over the years owing to its cost-effective nature.

What is Injection Molding Prototypes?

Currently, many Inventors, industrial designers, manufacturers, and others are seeking an ideal manufacturing process to meet the market demand in a short time span. This is where Injection Molding Prototypes play a significant role.

The Injection mold prototypes can able to a wide range of requirements in the plastic injection molding procedure. As the market needs a quick solution when it comes to different sorts of plastic products, Injection mold prototypes can be a great help. If you want to beat the competition to the marketplace, then don’t hesitate to use these advanced techniques that can save you time and money as compared to other conventional manufacturing methods.

In many cases, you might need to witness how numerous components of an assembly fit and function. Here Injection Molding Prototypes is the ideal solution. Quickly and cost-effectively, you can have prototypes which are also last a lot longer than they are guaranteed to.

Different Sorts Of Injection Mold Prototypes-

When we talk about injection molds, they can be built from aluminum, pre-hardened steel, or also non-metallic composites. Each metal has its benefits and specifications. However, aluminum is the most common type of metal used in prototypes and it is just because they are easy to machine and endure the injection molding procedure. At the same time, aluminum has different mold grades that are being used in this process.

We can say it is the most convenient that is tough and able to be processed in great detail. Aluminum is also four times conductive than steel which is the best part of it that helps reducing cycle times in molding. However, you need to take proper care of it when working with it.

Another great metal option is pre-hardened steel. You must know that pre-hardened steel and other types of steel are extensively utilized when it is the need for higher production. It can also give you fine details of the desired parts. They are easier to machine and polish. Different sorts of pre-hardened steels are available for use to yield the highest quality parts. You can use them as per your needs.

How Much Time Does It Need?

It depends on the customer’s demand. It usually takes 1-4 weeks to get a quality prototype. If the design is complicated, it may take a longer time. However, a reliable manufacturer can produce your desired premium quality parts within a deadline.

Few Tips To Thrive With Prototypes-

Working with Prototype Plastic Injection Molding will not only speed up the process but also lessen your expense. You can have the anticipated part without having essentially all the features that the final product might contain.

To get the best quality of Prototype Plastic Injection Molding Services, get in touch with 3ERP for a free quote. We’ll gladly offer advice about your best options. Combining our expertise, engineering capabilities, and advanced technology we can offer rapid tooling solutions.