Every industry and application is different, but metal parts often look and feel superior to their plastic counterparts. Metal provides a gloss and sheen, as well as the appearance of strength and durability. Plastic is incredibly useful, but metal often wins in the overall quality stakes.

On the other hand, plastic parts are often much cheaper to make than metal ones. The raw material is often less expensive, and manufacturing processes like injection molding make it easy to fabricate thousands of plastic parts in a very short space of time, at little cost. Additionally, plastics are often much lighter than metals, making them indispensable in applications where a part must remain lightweight.

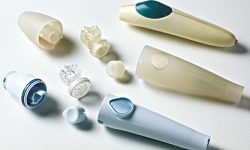

But what about situations in which a part needs to combine the benefits of metal and plastic? What if a part needs to look like metal or behave like metal on the surface, but remain both lightweight and affordable? Fortunately, there are several smart processes we can use to make parts that are plastic on the inside and metal on the outside. It’s not magic, but it’s very, very useful.

These processes can be grouped under the general name of metallizing or metallization. During a metallizing process, a metal coating is applied to the surface of the part, giving it a new, metallic surface layer that can be aesthetic, functional or both.

3ERP has years of experience adding metal coatings to parts of all shapes and sizes. Prototype or end-use part, a well-applied metallized finish can be the difference between a successful part and an unsuccessful one.

Why metallize a part?

There are many reasons why a company may want to add a metal coating to a part. These are some of them:

For starters, all metallizing processes are capable of radically altering the appearance of a part. A component made of colorless, matte ABS, for example, can be transformed into something sleek and glossy with a relatively inexpensive metallizing process. This is particularly useful for consumer products, where appearance is often as important as functionality.

Beyond aesthetics, metallizing can make a substantial difference to the functionality of a part. Because metals have different physical properties to plastics, a metal coating can have the effect of adding a protective layer to an otherwise vulnerable part. Metal coatings can be abrasion-resistant, making the metallizing process useful for parts that will have a physically demanding end use.

Another important property of metals is their ability to conduct electricity. By adding a metal coating to a plastic part, manufacturers can adjust the level of electrical conductivity a part for purposes like electromagnetic shielding. The process opens up new doors for engineers making electrical and mechanical components.

Benefits of metallizing:

- Aesthetics

- Protective layer

- Functionality

- Conductivity

Types of metallization

Metallizing is a general term used to describe different ways of applying metal to a non-metal part, and there are several vastly different processes one can use. At 3ERP, we offer many surface finishing options for metallizing your parts, each of which has its own particular benefits.

Our metallization services include:

- Vacuum Metallizing

- Chroming

- Chrome Sputtering

- Color Plating

- Zinc Plating

- Tinning

Metal on metal?

While metallization is often used to add a metal coating to non-metal parts, it is also possible to coat a metal part with a different kind of metal. Again, this could be for aesthetic reasons, or to provide a part with a new function.

One of the most common methods for adding a metal coating to a part is plating. Plating is famously used to add a desirable surface finish to jewelry, but its uses go far beyond that. In fact, plating is a highly versatile process that can be used to adjust finish, function and conductivity of a metal part.

Need to add a metal coating to the surface of your part? Get in touch with 3ERP to discuss metallization options, or browse our full range of surface finishing options for more ideas.