CNC milling is one of the most popular options for manufacturing prototypes and parts that entail cutting or drilling. The technology utilizes a rotating cylindrical cutting tool to cut or drill a design from metal or plastic material. Compared to traditional manufacturing techniques, CNC milling offers advantages such as high production speed, greater precision, and automated part cooling.

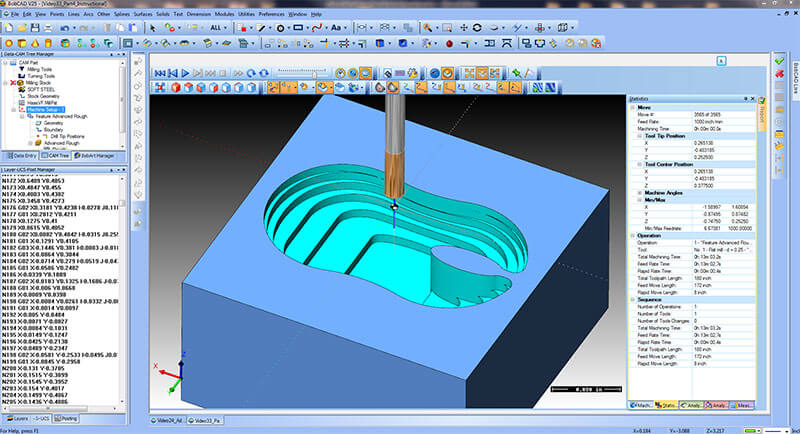

But before a designer can bring their design to life on a CNC machine, the model must first be sketched on CAD/CAM software. There are a number of steps you should take when designing an object for CNC milling process, here are some of the most important things you need to know.

Preparing CAD Models for CNC Milling

In most cases, the first step of the CNC milling process starts with CAD software, which is where you will create the model you wish to produce. Once the design is completed, you’ll have to convert the image into either the DXF or DWG file format. From here, the drawing will be imported into CAM/CNC software, where it will be transformed into G-code, the programming language that controls and directs the CNC milling machine.

There are a couple of techniques to use when designing models for CNC milling.

For instance, you can take an image and manually trace it using vector cut paths.

To do this, you’ll trace around the silhouette and the main features of the image, which can then be saved as a DXF file and imported it into a CAM program.

Another method you can use is automatic image conversion.

This includes scanning your sketch, saving it as a PDF file, and converting the image into a DXF file. From here, simply import the vector DXF file into a CAM/CNC program to generate the necessary G-code.

Sounds easy enough, right?

Well, there are still other crucial factors to keep in mind when preparing a CAD drawing for CNC milling. Although most CAM software programs will handle the preparation for you, you’ll still have to input certain settings and double-check various aspects of the model before exporting it to DXF.

How to Optimize Designs for CNC Milling

There are a plethora of ways to optimize your design to prepare it for manufacturing, and these factors will oftentimes determine how successful the outcome will be. Here are some tips to keep in mind when preparing a design for CNC milling.

Properly Implementing Cavities, Edges, Walls, and Holes

As versatile as a CNC machine might be, every manufacturing tool has its limitations. Therefore, it’s critical that the intricate sections of your CAD model are fully optimized for production.

Depth and Diameter of Cavities

When designing a model for CNC milling, you’ll always want to be weary of the depth and diameter of any cavities. For the most part, end mill tools are limited in cutting length, only capable of cutting three to four times their diameter. By limiting the depth of the cavity to four times the diameter of the tool, you can achieve first-rate results.

Edges

If you have internal edges and corners in your design, the diameter of the cutting tool will also have to be taken into account. If you’re hoping to achieve a high quality surface finish, you can increase the corner radii above the recommended value by about 1mm.

On the other hand, if your 3D model features internal corners that are at a 90 degree angle, add a T-bone undercut into the design.

Wall Thickness

You should also be cautious when decreasing the wall thickness of your model, as this can reduce the stiffness of a material, creating vibrations and lowering the overall surface finish quality.

- For designs that you intend to machine out of metal, keep the wall thickness around 0.8 mm or higher.

- If you plan on using plastic material, keep the thickness at 1.5mm or higher.

Creating Holes

Last but not least, creating holes in you CAD drawing will also call for some careful planning, particularly with the diameter and depth capabilities of the standard drill bit size. For holes that require tight tolerances, reamers and boring tools can be used.

When integrating threads into the model, keep the size at least above M2, preferably around the M6 mark or higher for the best results.

How to Integrate Text

Do you plan on inscribing a part number, description, or a logo into your part? There’s a few tips you should be aware of when creating a design with text.

- First off, the text inserted into the CAD model should have at least 0.5mm of spacing between each individual character.

- All text should also be recessed, using clear and concise fonts like Arial, Sans-Serif, Verdana, etc.

Get Rid of Overlapping Geometry

In order to confirm that the CNC milling process will go smoothly, you should check your model to eliminate any overlapping vectors.

Why is this so important?

Well, when a design has vectors stacked on top of one another, the CNC machine will go back and forth over the same area.

To optimize your model, delete any duplicate copies of objects, fuse all of the lines that overlap, and combine different sections of the design when properly aligned.

Place Geometry on a Single Layer

In addition to eliminating redundancies in your design, you’ll also want to clean up your CAD drawing before importing it to CAM software.

To do this, you can reduce your vector lines to the lowest possible number of nodes before the design quality is compromised. Additionally, make sure you only export the necessary parts of your model when converting into a DXF file.

Define the Scale of your Vector Image

Another way to optimize the CNC process that some might forget is scaling your vector image. Scan2Cad, a company that creates software for vectorizing CAD models into the DXF and DWG file format, suggests sticking to the system unit of millimeters as well as a precision or tolerance of around 0.5 microns.

Conclusion

If you follow these tips and refine your design for CNC milling, the quality of your final part will increase exponentially.

By utilizing 3ERP’s CNC milling services, you’ll have the luxury of seeing your design manufactured on professional-grade machines. Equipped with 3-,4-, and 5-axis CNC machining centers and experienced staff, we will help you deal with all the technical aspects of the process.

Still, using these tips to optimize your CAD drawing will prime your design for the CNC milling machine, leading to parts and prototypes with incredible precision and a high quality surface finish.