Stainless steel is one of the most commonly used machining materials. Stainless steel machining creates products and tools for every sector out there. Stainless steel machining is not as easy as materials like wood. Stainless steel has a high hardness and tensile strength. Therefore, machining stainless steel requires understanding the different metalworking processes that work […]

CNC machining has revolutionized the world of manufacturing, offering unparalleled precision and efficiency. One material that has stood the test of time in this field is brass, an alloy of copper and zinc. With its excellent machinability and unique properties, it’s no wonder that brass is a popular choice for numerous applications. In this comprehensive […]

In the world of machining, brass is one of the most versatile and sought-after materials for creating intricate and high-quality parts. This comprehensive guide will delve deep into the realm of brass CNC machining, exploring its advantages, brass grades and properties, tips for successful machining, available finishes, and factors to consider when choosing this process. […]

Plastic machining is one of the most common industrial processes due to the high usage of this material. However, modern-day plastic CNC machining isn’t what it used to be. Plastics nowadays can be built strong enough to stop a bullet’s impact. This calls for a very rugged machining method. CNC machining plastics has become a […]

Polytetrafluoroethylene (PTFE), most commonly known by the brand name Teflon, is a synthetic fluoropolymer thermoplastic that can be used for a range of applications, from non-stick frying pans to medical devices. Resistant to chemicals and stable even at high temperatures, Teflon is one of the popular CNC machining and milling plastics for many specific applications, despite its so-so […]

PEEK is a popular thermoplastic polymer found in objects as diverse as medical implants and electrical cable insulation. The plastic has excellent mechanical properties and a high level of resistance to corrosive substances, making it highly desirable for manufacturers across the world. Despite being regularly used for injection molding and 3D printing, PEEK has a […]

From cars to consumer electronics to kitchenware, Delrin is just about everywhere: the high-strength thermoplastic makes great consumer products and is favored by machinists for its good material properties and high machinability. This article goes over the basics of machining Delrin: what Delrin is, the benefits of machining Delrin, the limitations of machining Delrin, common […]

With its excellent strength-to-weight ratio and resistance to corrosion, titanium is one of the most useful and popular metals for industrial engineers, architects, and consumer product designers. It is named after the Titans of Ancient Greek mythology, after all, and it usually lives up to its name. Titanium has desirable material properties, and it is […]

Magnesium is a lightweight metal with high level of machinability that can be CNC machined to create parts with high strength and excellent corrosion resistance. However, magnesium can be difficult to machine due to its tendency to ignite or explode if proper precautions are not taken. It provides a hazard for CNC machinists: the chips […]

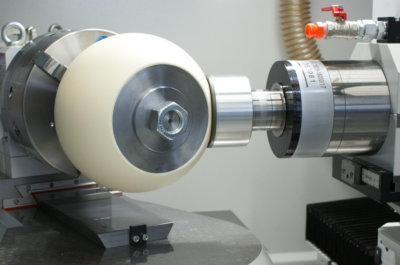

As a material widely used in everyday items from clocks to knives to bricks to pottery, machining ceramics can be a great way to expand a company’s materials portfolio. Though they are traditionally made using a kiln, machining them can be a useful endeavor that gives your machine shop a unique selling point. As a […]

For CNC machining projects, aluminum is one of the most popular material choices due to its desirable physical properties. It is strong, which makes it ideal for mechanical parts, and its oxidized outer layer is resistant to corrosion from the elements. These benefits have made aluminum parts common across all industries, though they are particularly […]

Aluminum is an important industrial raw material. However, because of its relatively low hardness and large thermal expansion coefficient, it can easily deform when being machined into thin-walled and thin plate parts. In addition to improving tool performance and eliminating the internal stress of the material in advance, there are several steps that can be […]

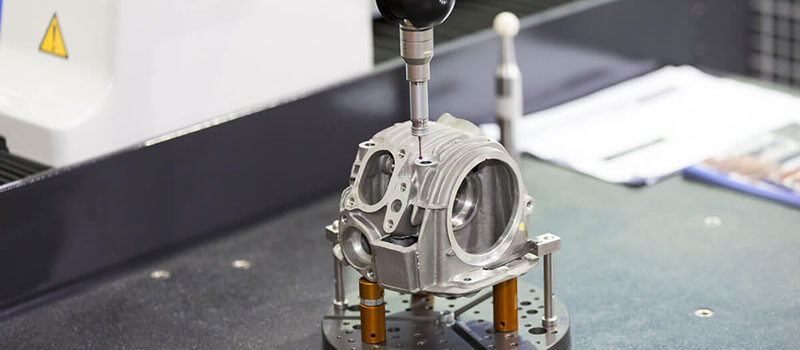

The CNC machining process is a great way to turn innovative designs into precise working models. However, users can only enjoy the full advantages of the process if they use the right CNC machining materials. Using the most suitable material can produce products that exceed your expectations. In contrast, not choosing the best CNC machining […]

Acrylic (PMMA) is a highly desirable material due to its strength, toughness, and transparency. But relying on conventional machining processes to cut acrylic can be a complicated procedure: the material is highly fragile and any excess force can cause unwanted breakages. CNC machining, however, offers a reliable way to fabricate acrylic parts safely, with a […]