CNC machines are hugely versatile pieces of equipment, in large part thanks to the range of cutting tools they can accommodate. From end mills to thread mills, there’s a tool for every operation, allowing a CNC machine to perform a variety of cuts and incisions in a workpiece.

Getting to know these cutting tools is a great way to understand CNC machining basics. And a better understanding of machining will help you design parts that are better suited to the manufacturing process.

This article looks at some of the most widely used CNC machining cutting tools, though there are many more out there besides those discussed.

What is a cutting tool?

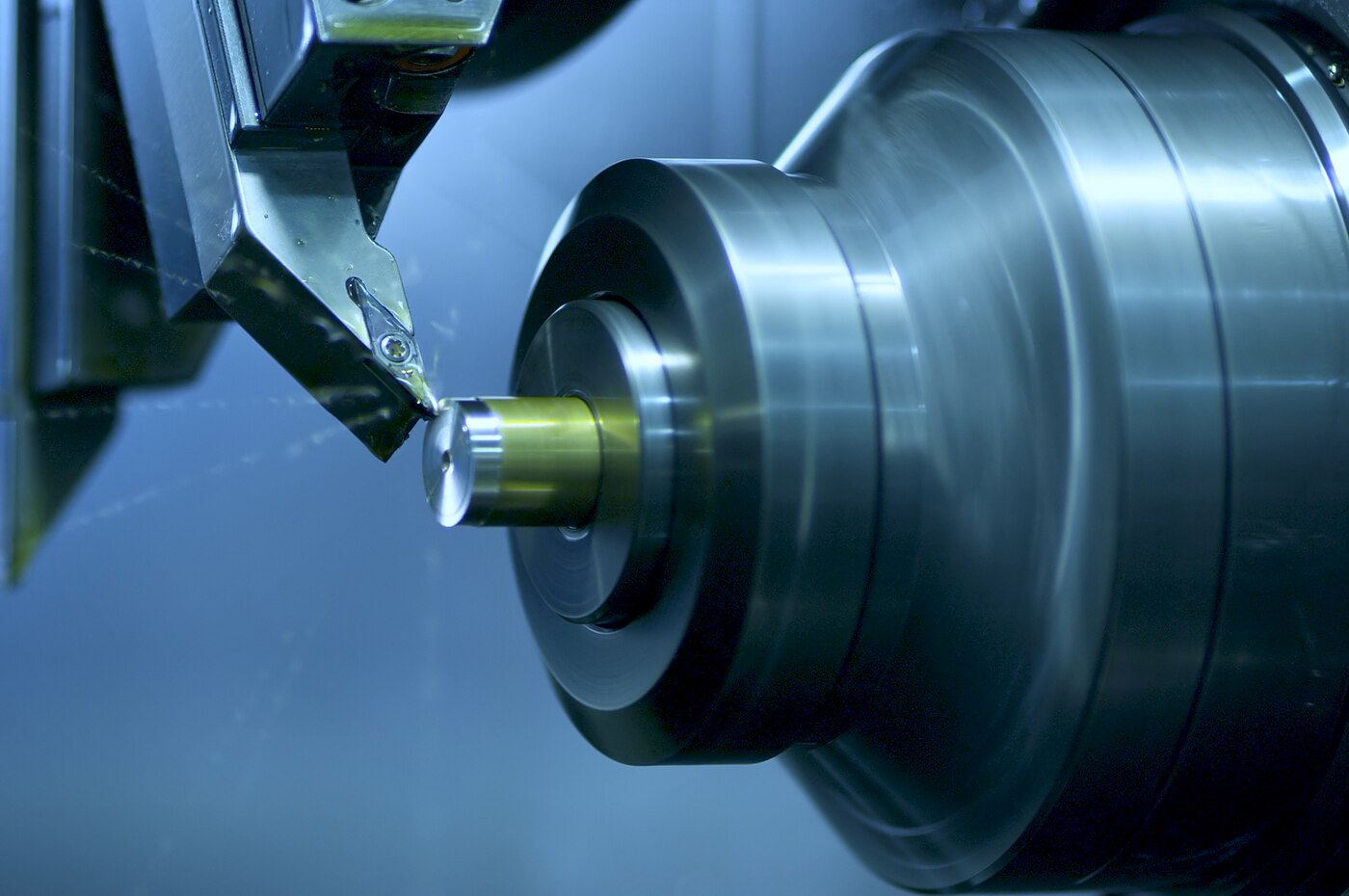

A cutting tool is a device used to remove material from a solid block of material. It is fitted to the spindle of a CNC machine, which follows computer instructions to guide the cutting tool where it needs to go.

Cutting tools remove material from the workpiece by a process of shear deformation. That is, the sharp tool rotates at high speed and cuts from the workpiece many tiny chips, which are then ejected away from the workpiece. Some tools make contact with the workpiece at one point only, while others, such as end mills, hit the material at multiple points.

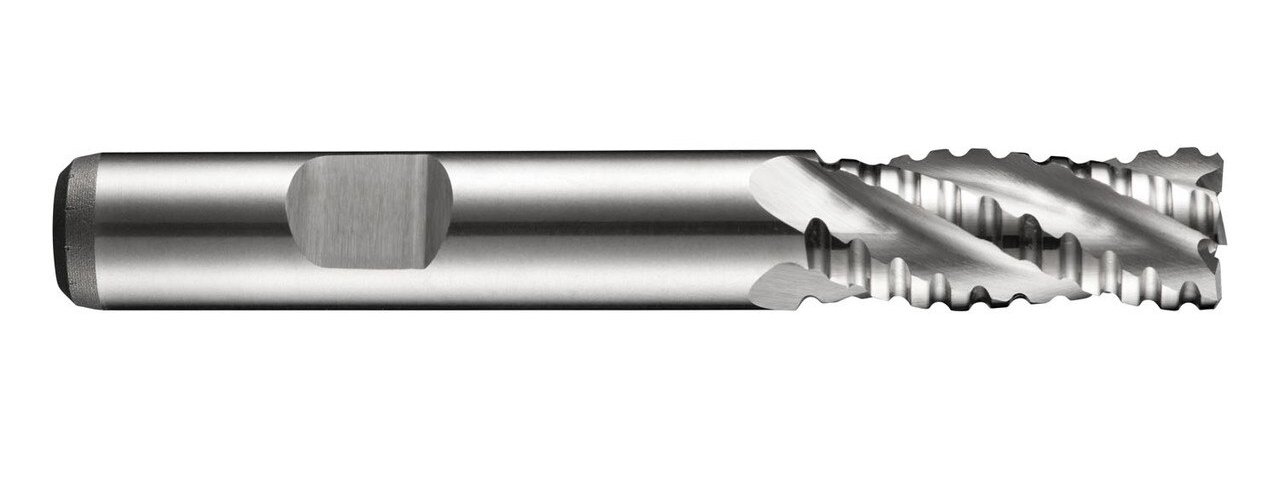

Most CNC machine cutting tools feature multiple flutes, which are helical grooves that run down the exterior of the tool. The flutes can be thought of as the troughs of the cutting tool, while the teeth, the sharp ridges between each flute, are its peaks. Chips cut from the workpiece travel down the flutes as they are ejected.

The ideal number of flutes on a cutting tool depends on the workpiece material. A tool with fewer flutes is preferable for soft materials, since the increased flute width means bigger chips can be ejected. A higher flute count can increase speed and is suitable for harder materials, but can lead to chip jamming, since each flute is narrower.

The type of cutting tool will affect the size of chip removed from the workpiece, and so will the spindle speed and feed rate.

Cutting tool materials

In order to cut through the solid workpiece, cutting tools must be made from a harder material than the workpiece material. And since CNC machining is regularly used to create parts from very hard materials, this limits the number of available cutting tool materials.

Common cutting tool materials include:

Carbon steel

Carbon steel is an affordable steel alloy containing 0.6-1.5% carbon, as well as silicon and manganese.

High-speed steel

The more expensive HSS is harder and tougher than carbon steel thanks to its blend of chromium, tungsten and molybdenum.

Carbide

Usually sintered with another metal like titanium, carbide tools are wear-resistant and heat-resistant, providing an excellent surface finish.

Ceramic

Used to cut superalloys, cast iron and other strong materials, ceramic tools are resistant to corrosion and heat.

Cutting tool coatings

The function of a cutting tool depends on its shape and material, but can also be adjusted with a coating over the main material.

These coatings can make tools harder, increase their lifespan or enable them to cut at faster speeds without compromising the part.

Common cutting tool coatings include:

Titanium Nitride (TiN)

TiN is a general-purpose coating with a high oxidation temperature that increases the hardness of a cutting tool.

Titanium Carbo-Nitride (TiCN)

TiCN adds surface lubricity and hardness to a cutting tool.

Super-life Titanium Nitride (Al-TiN)

Al-TiN adds heat resistance to carbide cutting tools, especially when minimal coolant is employed.

Diamond

Diamond provides a high-performance coating for cutting abrasive materials.

Chromium Nitride (CrN)

CrN adds corrosion resistance and hardness to cutting tools.

1. End mill

The end mill is the most widely used tool for vertical CNC machining. With cutting teeth at one end and on the sides, end mills can remove large amounts of material in a short space of time.

End mills come in many forms. Some have just a single flute, while some may have up to eight or even more. (Beyond four flutes, however, chip removal may become an issue.)

Types of end mill include:

- Flat: General purpose flat-faced tool suitable for 2D features

- Ball nose: Tool with ball-shaped end that is suitable for 3D contours and curves

- Bull nose: Tool with flat bottom and rounded corner suitable for fillets and roughing

2. Roughing end mill

The tool has serrated teeth that remove large sections of material but leave a rough finish on the part. It produces small chips which are easy to clear.

3. Face mill

Since the cutting edges of face mills are found on its sides, cutting must be done horizontally.

However, face mills can be more cost-effective than other cutting tools, since variations in cutting profile can be achieved by replacing the small cutter inserts rather than the entire tool.

4. Fly cutter

It is more common to find fly cutters with one tool bit, but those with two tool bits — sometimes called “fly bars” — provide a larger swing.

Less expensive than face mills, fly cutters can nonetheless be used for similar purposes.

5. Thread mill

Thread mills can cut internal or external threads, and may be better than taps for penetrating very hard metals or asymmetrical parts.

6. Drill bit

CNC machines can be fitted with a variety of drill bits for various cutting operations. Drill bits have one or more flutes and a conical cutting point.

Drill bits used in CNC machining include:

- Twist drill: Used to make holes in the workpiece

- Center drill: Used to precisely locate a hole before drilling

- Ejector drill: Used for deep hole drilling

7. Reamer

Reamers are used to widen existing holes in the workpiece, providing an exact hole diameter and an excellent surface finish.

Reamers can create holes with much tighter tolerances than other cutting tools.

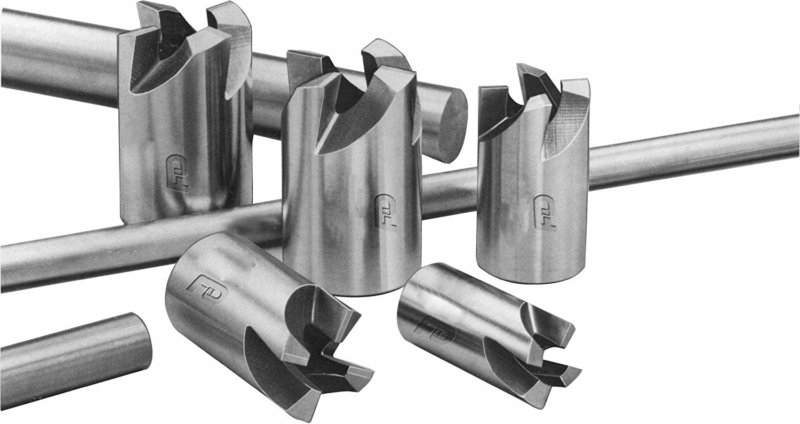

8. Hollow mill

Hollow mills are pipe-shaped cutting tools that are like inverted end mills. Their cutting edges are on the inside of the pipe shape, and they can be used to create shapes like full points and form radii.

9. Side-and-face cutter

Side-and-face cutters have teeth both on their side and around their circumference, and are suitable for unbalanced cuts.

These cutting tools can be used for cutting slots and grooves with fast feed rates. Their teeth can be straight or staggered.

10. Gear cutter

CNC mills are sometimes used to create metal gears for the manufacturing industry. Specific gear cutting tools can be used to make these gears.

Cutting gears sometimes requires a special kind of milling machine known as a hobbing machine.

11. Slab mill

Slab cutters or plain milling cutters are used to mill flat surfaces, usually with the target surface mounted parallel to the machine table.

These cutting tools have no side teeth, and can be used for general or heavy-duty machining operations.

3ERP provides professional CNC machining services for your prototyping and production needs. Get in touch for a fast quote.