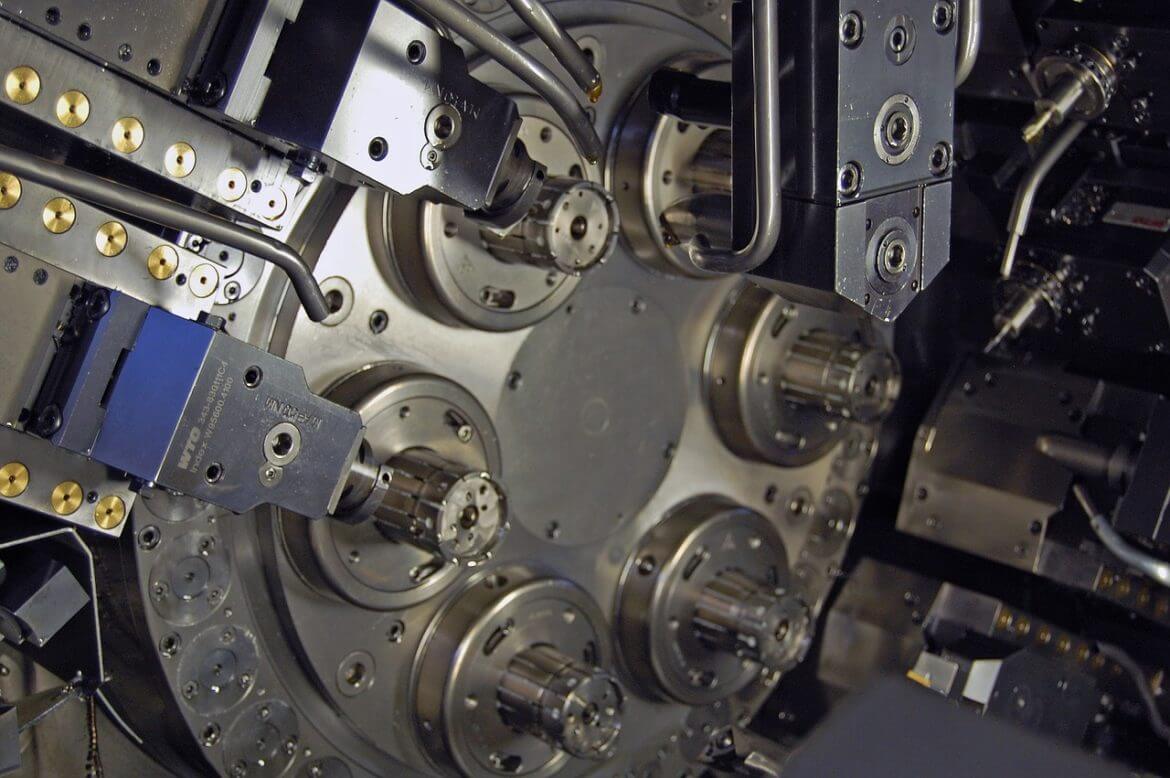

Mills, lathes and all sorts of CNC machines are marvelous machines, but they all require diligent care to keep them working under optimal conditions. Maintenance can be a hassle but it is necessary for any machine shop or even hobbyist to regularly undertake to avoid breakdown or operational inefficiencies.

As such, this article will serve as a basic introduction to the art of CNC maintenance, providing rough guidelines that should work with most standard mills and lathes.

Important note: the information within this article is compiled from recommended practices from dozens of manufacturers and is meant as a basic outline that applies to most machines. More specific maintenance rules may apply to particular machines on a case-by-case basis, so it is important to keep in mind that such practices may vary across different systems. However, these serve as a useful general rule of thumb across a variety of machines.

Regular Daily Check-ups

First and foremost, it’s important to create a regular cleaning and maintenance schedule for your device, no matter what it is. Top of any schedule are your daily duties, while others can be weekly or monthly.

The proper way to divide up the various parts of the schedule can be subject to individual devices and there are some variances, but the following information should be sufficient for most CNC machines.

Daily tasks that apply to most machines include regular check-ups for the hydraulic fluids and pressure systems.

Okuma, for example, recommends 4.5 MPa of pressure as the ideal level to keep their lathes at optimal efficiency. These check-ups also involve maintaining a feasible chuck pressure and refilling the fluids as necessary. The same goes for the lubrication levels.

In terms of physical activities that need to be carried out daily, wiping and greasing various machine parts is a must. Sometimes this is as simple as wiping the machine while other times it may require degreasing all the components.

Key components you need to have could include (at minimum):

- rubbing alcohol

- brushes of varying sizes (toothbrushes can also be great for certain sections of the machine)

- plenty of cloths and rags

- metal polish

- a fair bit of water

These items can make most daily cleaning activities easier, but for more intensive cleaning on complex devices you may also need items like a keycap cleaner, window cleaning apparatuses and industrial grade rubbing compounds.

As you can imagine, the inventory highlighted above is for cleaning the windows, metal components, clearing the grease and lubricating various parts with hydraulic oil for smoother motion. This should be done as regularly as possible because such smaller oversights can pile up easily.

Another recommendation from Okuma is to take the filter off the CNC control cabinet and clean it so air will be able to flow through for cooling. They recommend this as either on a weekly basis or every 40 hours, as is deemed feasible.

Weekly Duties

Various companies recommend having more intensive check-ups performed by professional engineers approved by the distributors themselves. One can contact the company and know the locations of the closest repair shops in your area. However, this isn’t always an option.

Some cleaning duties are best kept on a weekly or monthly basis or till the machine has been operational for a sufficient amount of time. About every 500 hours, it is best to check and grease the chain on the chip conveyor, along with removing any stray chips and material fragments. It’s also important to check and clean the filters on the coolant tank in this time frame as well.

Haas recommends some specific weekly duties for Vertical Milling Centers. These machines may also require regular debris cleaning from the automatic pallet changer, receiver pallet clamped switch and Receiver areas.

Long-Term Duties (Half a Year to Annual)

Every 6 months or more, extensive cleaning is highly recommended. This involves removing sludge, chips and oil from the coolant tank. Cleaning the chuck and jaws is also an essential part of such duties. The hydraulic tank also require regular draining, along with hydraulic oil replacement, line filter and suction filter changing.

Cleaning the radiator and making sure the radiator fins are straight is also a crucial duty for about every 6 months. Aside from renewing the lube within, it’s important to drain the lubrication unit and clean it out. If your machine is equipped with a cooling unit, have the unit drained and refilled.

Crucial checks to perform include the leveling of your machine. If the levels are off adjust it as necessary. Wipers should be inspected for any damage, cleaned and replaced where wear and tear has occurred.

On an annual basis specialists and maintenance crew should keep their eyes open for certain things like tapering on the headstock and the tailstock. More crucial checks include inspecting the spindle for radial and end play, checking the chuck cylinder for run-out and adjusting the X and Y axis gibs when necessary (usually after running a backlash program).