In simple words, injection molding is a manufacturing process that is used to inject molten material. When the molten metal is injected into the mold, the outcome will be your required parts. Plastic Injection Molding is specially intended for the production of plastic parts.

Different projects require different sorts of parts and they vary with different sizes, applications, and complexities. The Plastic Injection Molding process has got it covered. However, the molding should be carried out with full precision. In this process, the molten plastic is injected into a mold which then solidifies and gives rise to the final product.

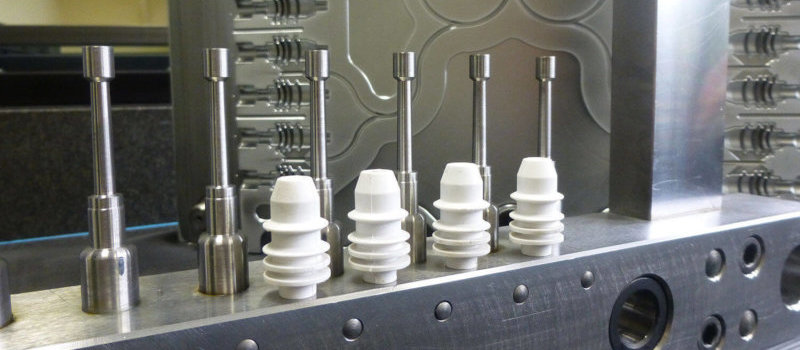

When it comes to the required material, it needs an injection machine, a mold, and plastic raw material, and all these help in executing this process. This process is highly appreciated by the manufacturers to produce required plastic parts or products. In addition, the efficiency and cost-effectiveness of this process make this molding procedure stand out from the crowd.

However, do not make a wrong decision while choosing a manufacturer for your next molding projects. It could be less effective for you or can lead to a big loss. Make sure you are in the right place for a reliable and highly experienced manufacturer that provides superior Plastic Injection Molding Services at a competitive pricing range.

By hiring the best injection molding manufacturer, you can able to obtain the best deal as well as various benefits that you are seeking for.

All the key pros are given below-

Excellence with detailing-

When you are opting for this technique to produce your required parts, it is absolutely possible to add details to the products by using injection molding as the molten plastic is exposed to high pressure against the mold. The mold is nothing but the standard that leads to excellence.

Power and competence-

As in this process, fillers are to be added in the injection molds, it enables the plastic material density to be condensed and it produces stronger parts that will go beyond your expectation. And customization options can be performed for precise parts. When we talk about the competence of this manufacturing method, it improves with the time as time is taken only in the start to make a mold and melt the plastic. It requires less time to produce several products at the same time which is the best part of it. Also, the same mold can be engaged many times.

Automation-

It is an automation process that enables produce high-quality parts sans hassle. It involves Computer-aided design (CAD) and computer-aided manufacturing (CAM) in helping to design the product molds. The automation brings aptness in design as well as enables low manufacturing costs to finish the products. Also, it reduces labor costs. It provides benefits to customers.

In a nutshell, the aforementioned benefits make this technique stand out as compared to other traditional manufacturing processes. Therefore, most of the manufacturing companies use the Plastic Injection Molding process.

It offers low cost, high efficiency, and quality products according to the requirement of customers. Hence, this is a great investment. Do not hesitate to opt for Plastic Injection Molding Services to get your plastic parts.

3ERP is a leading provider of Plastic Injection Molding Services at the best pricing range. Let our experts handle your injection molding projects.