With the continuing growth of additive manufacturing, companies and researchers have come up with various sub-technologies, add-ons and means of optimizing prints. However, another means of achieving an optimized object is to optimize the material being used. This has given a rise to various materials made for 3D printing, all of which exhibit ideal properties achieved through precise control.

Some of these materials have been designed very specifically for or with 3D printing and thus present the technology with new, novel characteristics and features. Here are some of the most promising materials:

Scalmalloy

Photo Credit: Beamler

Touted as the first original material specifically developed for 3D printing, this mixture of scandium (SC), aluminum (AL) and magnesium (M) all in amalgamated into a single alloy. The material was originally developed and patented by APWorks, a subsidiary of the Airbus group. As a metal printing material, it presents some unique features like enhanced strength (mostly due to the presence of Scandium).

In terms of strength, it can outmatch traditional aluminum and a lot of its derivative alloys. It’s even stronger than titanium in conjunction with being lightweight and corrosion-resistant. Of course, the material can be expensive to create because it contains Scandium, which is a rare metal that is also expensive to extract from its ores. Prices or Scandium can fluctuate between US$4000 and US$20,000 per kilogram, with the primary mining locations being in China and Russia.

Scalmalloy is most useful for high-endurance, long-lasting parts. This is why it’s becoming popular in the automotive industry and robotics, often being part of heat exchangers. As one might suspect, Scalmalloy also plays a pivotal role in its industry of origin: aerospace.

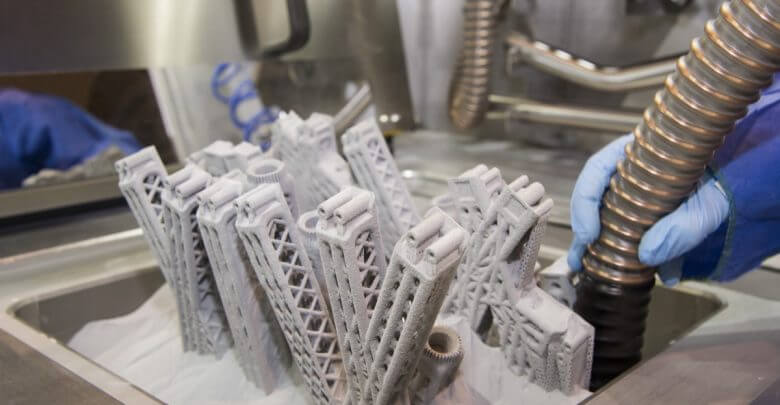

NewGen SLM Materials

Photo Credit: TU Graz

This metal came courtesy of Austria’s TU Graz, applying a blend of silicon nitride to developing metal-AM dedicated Stainless Steel. Referred to as NewGen SLM materials, they present more controlled reactions during the formation process, resulting in improved surface finish and minimizing the need for supports. 316L stainless steel is one of the most common materials with uses in multiple industries worldwide and the NewGen version presents improved characteristics specifically for printing with Selective Laser Melting.

The researchers tested out various version of the modified stainless steel concoction with multiple blends. In testing other materials for mechanical properties and porosity, they arrived at the conclusion that distortions in sintering were reducible through strict control of the silicon nitride and borons within it. They published these findings in the academic article “Improving the Dimensional Stability and Mechanical Properties of AISI 316L + B Sinters by Si3N4 Addition“.

As borides increase the density of the sinter, they don’t merge well in iron-based materials. As a result, unwanted layers can form around the particle. Silicon nitride mitigates this factor and leads to better surface finishing. The researchers have modified the metal powder for not just better mechanical and end-use properties, but also so NewGen SLM materials require fewer support structures. In doing so, the modified stainless steel can be even lighter than conventional metal prints.

Currently, the researchers are still commercializing this particular material. They are also enhancing this line of research to test for other such materials that may benefit in similar ways. Their work has received notice and they are working with a spin-off fellowship program to establish a proper start-up.

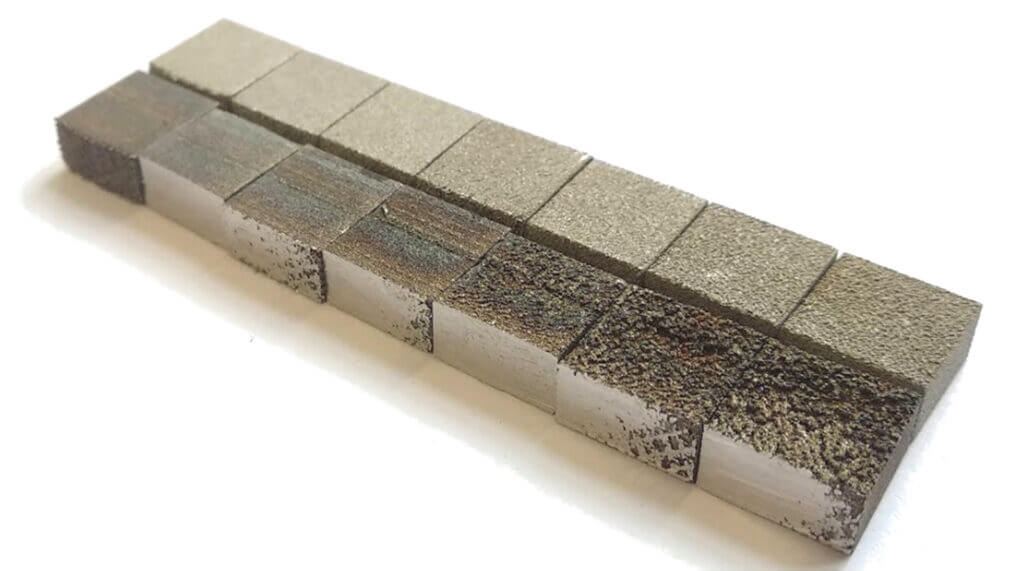

3D Printed High-Strength Aluminum Alloy

https://www.youtube.com/watch?v=8YwlenA4bdg

Invented by HRL Laboratories, this particular strain of aluminum was recently commercialized and registered by the Aluminum Association. The additively manufactured high-strength aluminum, also marked the Aluminum Association’s first ever registration of such an alloy, receiving the registration number 7A77.50 for the aluminum powder, and number 7A77.60L for the printed alloy itself.

This material was also special in that it marked the association’s new additive alloy registration system back in February of 2019. This was a direct result of the various new materials cropping up due to additive manufacturing capabilities. This was the first alloy of its kind to be printable.

Chemically, the alloy was developed using HRL’s nanoparticle functionalization technique. This particular material uses zirconium-based nanoparticles, however, the real advantage of this mode of material production is that it could be applied to a wide variety of other metals and alloys often deemed unprintable. As a result, HRL are also looking into the various other ways new materials can be brought into the 3D printing world.

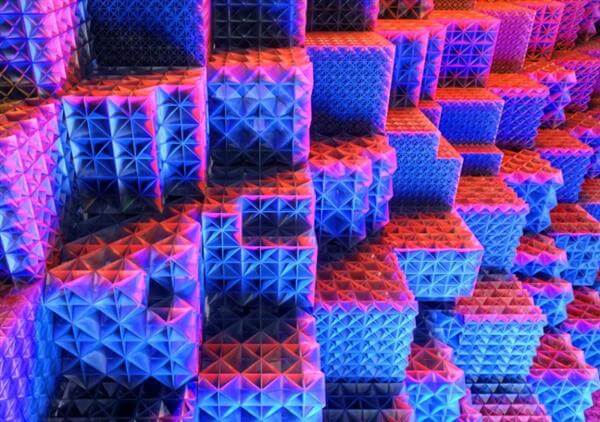

Crystallography, Metamaterials & the World’s Stiffest Plastic Structure

Photo Credit ETH Zurich/MIT

New material arrangements aren’t always about discovering a new material or altering the chemical composition of a material to make it printable as previous examples illustrate. Sometimes a new way of using existing materials can provide something extraordinary. This was the case with various material structures that contained materials structured in such a way that they produce exciting results.

A combined project between MIT and ETH Zurich poses as one example. Researchers created a material with the highest stiffness to weight ratio possible by rearranging the construction of plastics on the nano-scale. This resulted in a material that was very rigid, while also balancing this stiffness with a relatively low weight. In essence, they had developed the stiffest material possible, being fairly close to the theoretical limits that physics allows by simply tweaking the ways its microstructure is arranged.

This sort of stiffness to weight ratio is crucial for high-strength medical implants, planes and racecars. As mentioned previously, the main idea is not as much in the material in use as it is in the construction on the micro-scale. With the use of intricate patterns of trusses, girdles and arches, the researchers maximized strength and endurance.

Similarly, the University of Sheffield and Imperial College researchers were researching the use of novel microstructures in prints to improve durability, hoping to create new ways of printing alloys. Their work in the use of crystallographic metamaterials made use of computer atomic modeling to create these never before seen structures. These crystal structures, as they described them, result in prints that come out without grain boundaries, being continuous and unbroken. This gives the end print better damage tolerance, strength and toughness.

Such materials have periodic arrangements of nodes and struts, making them lightweight while exhibiting a combination of properties that do not occur in conventional solids. By employing the hardening mechanisms found in crystalline materials to develop materials that are robust and damage-tolerant, they created printable materials that subtractive manufacturing could not possibly manage.

A similar idea permeates the field of 4D printing, where microstructures are so delicately balanced they turn average materials into robots or functional items with various arrangements. 3D printing often provides these abilities to tinker the minutest details till they serve a designed purpose and encourages the creation of new forms within the world of manufacturing and research.