3ERP has covered many of the different ways automobile manufacturers are benefiting from the advantages 3D printing brings to the forefront. As technology is gaining a more mainstream foothold within the automobile industry, many companies are taking note, but many are using it in different capacities and for various purposes. These needs can encompass anything, from tools to spare parts/supply chain management to end-use parts and even full cars.

It’s interesting to see how far the technology has come, how it’s employed by the big names in the industry and where they see it going fort their future production chains. This article aims to provide insight into the many ways some of the biggest automobile manufacturers in the world use 3D printing in their workflow.

BMW

As most 3D printing is used for smaller volume production runs, there is a lot of room for customization and adding complexity using the unique elements that 3D printing allows. BMW is no stranger to such forms of design and manufacturing, employing 3D printing in pre-development, vehicle validation, and testing, or in concept and show cars. They employ the technology for larger volumes, but smaller production runs allow them to personalize products precisely to their customer’s needs.

The company has been prolific in their use of additive manufacturing, noting that they potentially see “great future potential for serial production and new customer offers” (according to BMW’s experts in Germany). They’ve been using the technology to enhance both plastic and metal components. They’ve most famously been working with HP to produce products on their large scale manufacturing systems.

Like many other companies on this list, BMW has been using it as a means of producing parts that other technologies cannot create. A good example of this is the i8 Roadster’s top cover. Making the mounting for this component would not have been possible using a traditional casting process. Aside from expanding the design possibilities, the 3D printed car part is more durable and it also weighs less than previous iterations.

Similarly, BMW unveiled the iFE.20 Formula E racer with a 3D printed cooling shaft manufactured from flax fibers. The part was shown off at the end of 2019. Compared to the usual carbon materials, flax has greater absorption and greater impact resistance, which can be advantageous on the street circuits with their bumps and crash barriers, on which Formula E takes place. This made it the first BMW racecar fielded by a work team with parts made out of renewable textile fibers, also making it environmentally friendly.

BMW’s Gloves With Protected Thumb

The company uses 3D printing for tooling and safety as well. A good example of this is the specialized gloves they use to finish off the stoppers for drain holes. These stoppers have to be manually set with the engineer’s fingers, which means a lot of strain on the thumbs. Luckily, they came up with the 3D printed solution that could be fitted onto the work gloves.

Even aside from their work on their own automobiles, the company’s engineers have been lending a hand to outside projects. One example is the development of the bespoke 3D-printed seats for the British Paralympics Basketball team. Using 3D body scans and the latest in additive manufacturing, BMW’s engineers constructed a whole fleet of wheelchairs allowing for players to display a more advanced level of athletic prowess.

Ford

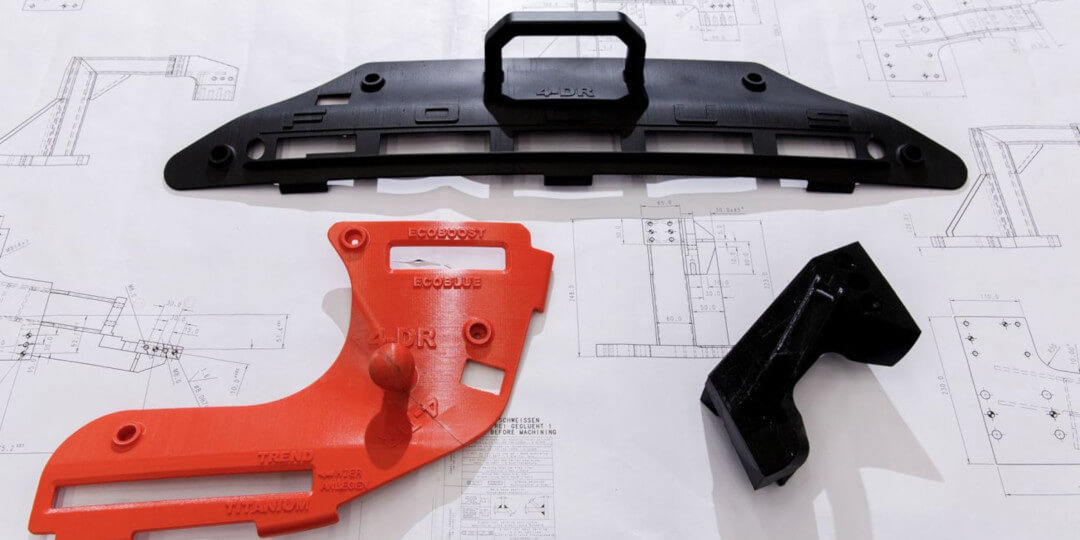

Ford’s Jigs & Fixtures

As far as commitment to 3D printing goes, Ford is running headfirst into embracing the technology. The company set up an additive manufacturing center and employed its operations extensively into their workflows. In terms of creating plastic and metal prints, they’ve had a long-running partnership with various companies such as Ultimaker, Stratasys and GE Additive, who provide machines for all sorts of AM applications across the production chain.

They also use 3D printing to cut cost and time for tooling, as the company found that it was quicker to make their own parts on the facility as opposed to waiting for suppliers and other such things. They also apply these same principles to jigs and fixtures, which they develop in facilities all over the world.

They’ve expanded their 3D printing operations over the course of the past few decades, manufacturing both metal and plastic components. As the company states: “In the last few decades, Ford has printed well over 500,000 parts and saved billions of dollars and millions of hours of work. Where it would have taken 4-5 months and cost $500,000 to produce a prototype with traditional methods, a 3D printed part can be produced in a matter of days or hours at a cost of a few thousand dollars”.

Similarly, Ford’s various subsidiaries have been showing off their AM chops, most notably the design teams behind the Shelby GT500. This year, they 3D printed the most promising designs for the new GT500 in a matter of days, which sped up the improvement and testing stages immensely. This pace allows them to rapidly tweak the Shelby GT500 little by little, bringing in new physical designs at breakneck speeds. They also developed a new spoiler-wing hybrid design that the team is calling ‘the swing’. This new design is a prominent factor in the GT500’s impressive aerodynamic capabilities.

EcoBoost Engine

The company set another major 3D printing milestone back in February. Their Ford Performance division, dealing with high-performance components, 3D printed what they claim is the largest metal automotive part for a working vehicle in automotive history. The metal part was installed in the Hoonitruck, a 1977 Ford F-150 with a twin-turbo 3.5-litre V6 EcoBoost engine. The part itself is an aluminium manifold inlet, printed using GE Additive’s Concept Laser X LINE 2000R.

Volvo

While not the most prominent user of automotive 3D printing, Volvo has been making great strides on this front in recent years. Much like a lot of the other companies on this list, Volvo has been using 3D printing for tooling and supply chain management. The use of 3D printing has particularly been useful in restocking the company’s machines with new prints for out of production parts. Volvo is mostly using 3D printed plastic parts and is looking towards the implementation of metal ones in the near future.

As of 2018, the company was using additive manufacturing primarily for prototyping and tooling. “As we only need to produce low volumes of parts for prototyping, it’s a good way to see what works,” says Fredrick Andersson, Development Engineer for Wheel Loaders Powertrain Installation at Volvo CE [construction equipment]. “We have a lot of knowledge and we can make changes quickly and easily with 3D printing. And because of this, it means that the time to market for a new product is quicker, so it’s of great benefit to our company.”

The increased speed of prototyping has been massively helpful to the company, as various new tech they were testing proves. For example, Volvo engineers designed new water pump housings for the company’s A25G and A30G vehicles. They ran simulations as a means of optimizing the design of internal flow passages in the housing, but needed to build a prototype to perform functional testing to validate the new design. The tooling cost for this project would have been approximately $9,090, with the part cost around $909. The lead time for producing the prototype would have been 20 weeks minimum. On the other hand, 3D printing the prototype cost $770 and took only two weeks.

However, in 2019 the company upped the ante in terms of its AM processes, particularly with its Volvo Trucks branch. Their New River Valley (NRV) plant in Dublin, Virginia made quite a few headlines this year among the manufacturing world. They primarily use SLS but have also dabbled in other AM methods. This particular facility produces over 500 manufacturing tools and fixtures in use on the shop floor produced using 3D printing. The facility is also a major hub for North American automotive engineering.

Aside from commercial automobiles, the company also develops construction equipment. Sure enough, 3D printing has also made its mark on this aspect of the company’s operations. Volvo applied 3D printing in re-tooling their articulated haul trucks, and thus cutting down the cost of prototyping by a tenth. This also allowed them to reduce the time spent from 20 to merely 2 weeks.

GM

General Motors, and its various other branches, are major users (and developers) of 3D printing technology. As of 2018, GM was saving $300,000 a year on tooling and is making sufficient advances towards the development of new technologies using alternative fuel sources. The leading automaker announced last year it plans to launch 20 new electric and fuel cell models globally by the year 2023.

Although their 3D printing operations have largely been about prototyping, they are expanding. The company further plans to scale up their printing operations to produce “tens of thousands of parts at scale as the technology improves,” according to Kevin Quinn, director of additive design and manufacturing at GM. This plan is likely to unfold over the next 5 years.

The company’s Warren Tech Center produces roughly 30,000 prototype parts each year. The parts consist of at least nine sorts of materials, employing combinations of plastics and metal and powders. They are primarily used for prototyping but the company is also looking at end-use parts. They also co-own HRL laboratories with Boeing, who ended producing a 3D printed Aluminum alloy.

Dan Grieshaber, GM’s director of global manufacturing integration, stated the majority of GM’s factories have 3D printers now. The company plans to increase it even further, at least within their North American factories. The move is likely to save GM millions of dollars in production costs annually. GM has long been an investor in 3D printing and it’s various sub-branch technologies. They are applying it for the rapid building of tools and accessories for workers in their plants. Just this year, the company stated that the implementation of a $35,000 3D printing machine has saved the company $300,000 over two years. While tooling production is the primary role that the printer plays, it may be possible that the company will increase the role of additive manufacturing in their daily operations.

GM’s Bracket Developed in Collaboration With Autodesk

Their partnership with Autodesk has been beneficial in manufacturing lightweight 3D printed parts that could help the automaker meet its goals to add alternative-fuel vehicles to its product lineup. Also part of this same collaboration, in 2019 both companies showed off 3D-printed seat bracket made of stainless steel and developed with the Autodesk technology.

Early in 2019, GM was looking at a novel new design application for 3D printing. In collaboration with Michellin, they were looking to produce a new type of tyre with superior durability. The Uptis tire is still a work in progress but the companies have moved on to the testing phase. They claim the tires would be 100 percent sustainable, resistant and able to last even longer. They are also a much greener alternative, with less waste during production. Recently, engineers were using a fleet of Chevrolet Bolt EVs to test the new tires in Michigan, and have floated the possibility of making them available to the public in 2024.

Porsche

Porsche has been using 3D printing for a range of different purposes, from major components to reinventing the supply chain for their older models. Porsche is currently using 3D printing to produce very specific spare parts, but not that extensively. This is due to the stringent quality standards they need to conduct to ensure the safety is up to scratch. The company also works with a lower overall number of units produced as they are more of classic and luxury car brand.

For the development of out of production components such as the release lever for the clutch on the Porsche 959, the company employs laser melting. They make use of powdered tool steel and get the part out far more efficiently than it would be otherwise possible with alternative methods.

The use of 3D printing has also allowed the company to move towards on-demand printing, allowing for far lower costs associated with materials, transportation and storage. This is also beneficial as these parts are not in greater demand and are often expensive to keep in constant production. Porsche has most famously been working with Markfordged on reviving these classic parts.

Mainly, they use SLM and SLS for the various parts they need to produce. Porsche has stated that the 3D printed parts are superior to the older ones in many cases. While they are printing a limited number of parts currently, they have been expanding the portfolio since 2018 and testing future components.