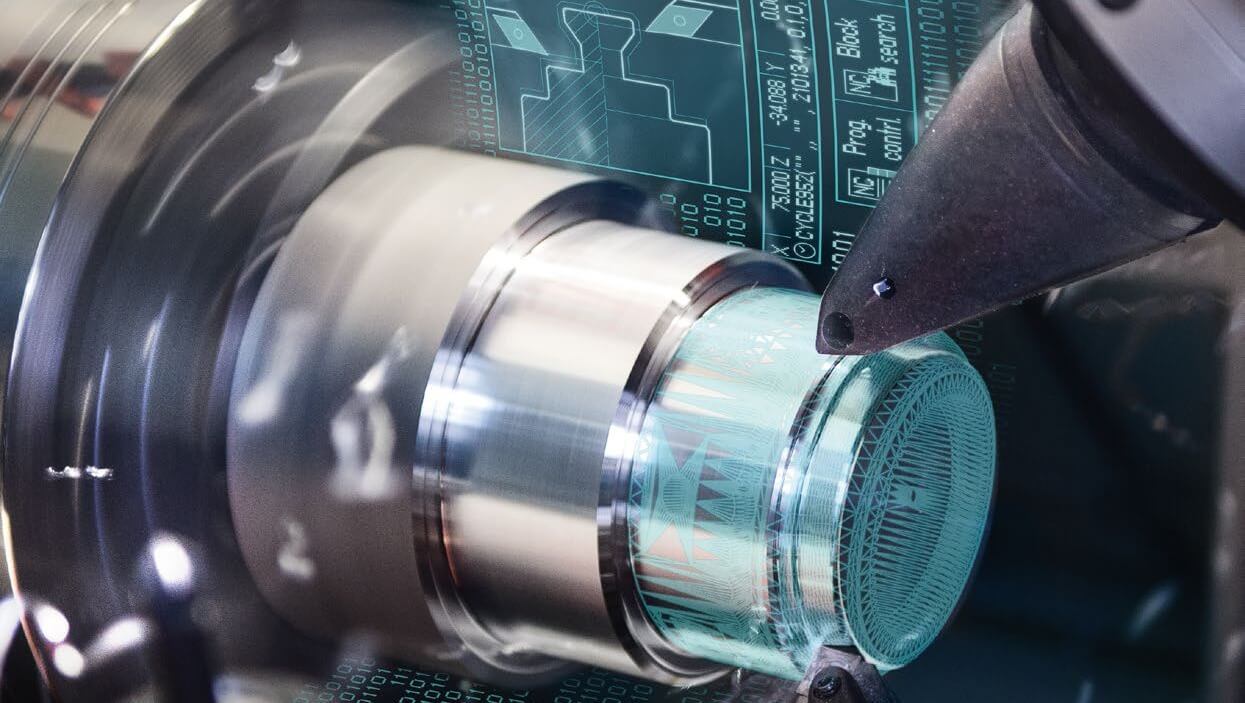

The energy sector is the lifeblood of modern society, powering all our devices and industry continuously. Consequently, this constant, vigilant production of energy requires all sorts of advanced equipment, from hydraulic valves for the oil and gas industry to solar cells to wind turbine parts. CNC has been crucial in creating these complex devices.

Aside from aerospace and automotive, energy production is one of the biggest uses of CNC machining. However, the energy industry is at a turning point where it may have to make room for newer, greener forms of power alongside conventional energy sources, or (more radically) abandon oil and gas for renewables altogether. After all, the renewables sector grew by 5% every year from 2007 to 2017, with more initiatives and growing global backing also increasing.

In general, CNC parts and advanced machining will increase the quality and efficiency of the power generation tools and parts. This article will look at some of the major ways in which CNC is playing a crucial role in this shift.

Wind Power

Wind energy production requires durable, long-lasting parts that can take enormous stress while maintaining accuracy. Manufacturers have to produce precise blades for handling wind pressure with minimum wear and tear. Metal and carbon fiber machining has been crucial not just in the production of the blades, but also in parts like the giant bearings that adjust the angle. With the use of CNC, the giant bearings in a wind turbine’s adjustment mechanism can be manufactured with accuracy typically reserved for smaller parts. As these are massive parts whose mobility severely impacts their performance, they (much like airplane engine blades) need to be severely accurate.

Generally, multi-purpose lathe machines are used for gears, gearbox housings, and rotors. Considering the size of the average wind turbine, it requires large, heavy-duty machines, with about 90% of gear wheel manufacturing involving metal cutting. These days, this is dominated by gear milling, using a hob or disc cutters. Similarly, CNC drilling machines are often used for processing holes in tube shell heat exchangers for a variety of energy systems.

With wind turbines and windmills, there is a need for CNC machines that process reinforced carbon-fiber plastics or glass fiber materials. In terms of materials, fiberglass with a hollow core, aluminum, and lightweight woods can also be used for the rotor blades. The blade profile of most rotor blades is quite similar to that of airplanes, so these machines require quite some heavy accuracy.

Solar Power

Aside from the solar panels themselves, there are various parts that need precise manufacturing, like frames, back rails and carrier rails. Milling and drilling machines are ideal for such projects and many companies market their CNC machines as specifically for producing solar panel parts. Even large solar panel production lines incorporate multiple types of CNC processes like cutting and drilling, but also require multiple non-CNC processes in conjunction with operators working simultaneously.

Since production lines can be massive and gaudy, companies like Fanuc have been offering versatile robotic arms that can handle shapes with more flexibility and economy of workspace. Similarly, companies like Beam cut are offering software that specializes in solar panel fabrication that simplify the process and only require a single person to operate. This is one of the ways in which CNC is freeing up space and labor utilization.

Solar panel manufacturers are very often using turning centers and wire cutters for frames and housing. Plasma and fiber laser cutting machines often specialize in solar panel manufacturing, with various lasers often being used for dividing the panels themselves. Similarly, companies like Protolabs incorporate a mix of CNC machining and 3D printing to produce solar panels. This does indicate that there may be space for hybrid manufacturing within the solar power industry.

Hydro Power

Hydropower turbines and generators are not just massive machines. They also need to be durable against pressure and water damage and composed of metals that possess these same qualities, often utilizing carbon and stainless steel parts. Companies all over the world use CNC technologies to produce all sorts of components from simple shafts and bushings to hydro turbine housings, impellers, and covers.

It involves the usual turning, line boring and milling but often on a massive scale, depending on the needs of the plant. For reference, Canyon Hydro in North America uses a 7-axis CNC milling machine capable of fabricating Pelton and Francis hydroelectric turbines up to 16 feet in diameter while weighing 25 tons. The CNC machine corrects minor (yet potentially impactful) imperfections in the turbine. This is among many other machines in their fabrication center. On an even bigger scale, Voith Hydro’s York facility machines workpieces that can be over 42′ (12.80 m) in diameter and weighing more than 350 tons (317.5 t).

Aside from turbines, CNC milling and other machining technologies are used for developing the gates of dams and hydropower stations. In certain cases, the growth of various CNC machines has allowed for the production of such parts to happen on-site, as opposed to being brought in from a far-off factory.

Overall, the world of green energy is benefitting immensely from CNC machining and modern technologies. We’ve only just scratched the surface of their capabilities, yet there are already so many applications, advantages, and use cases.