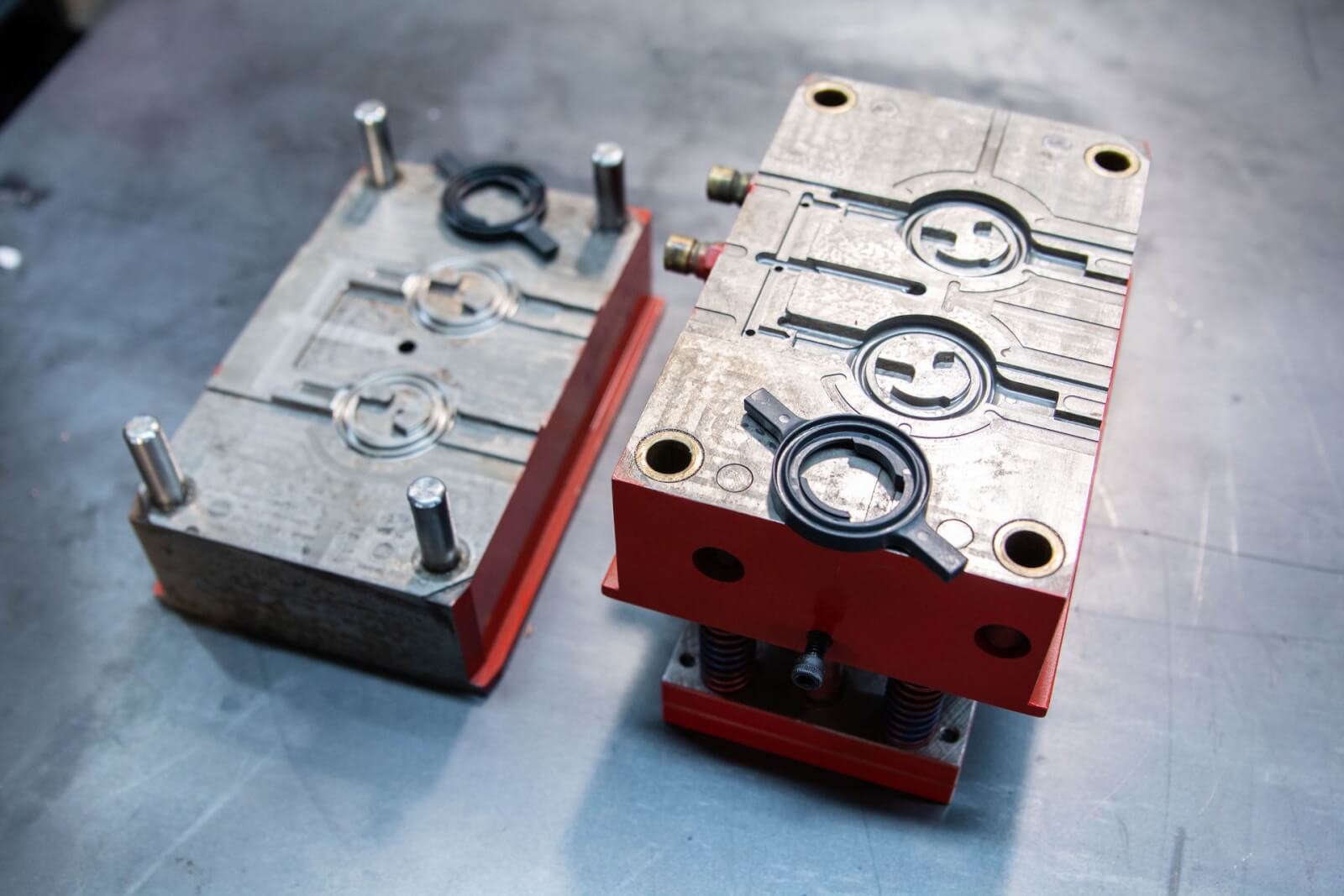

Prototype molding- what it is?

When we talk about Prototype Molding, it is specifically intended to produce prototypes rapidly and small to medium series of plastic parts. In a nutshell, we can say this is the most convenient method to produce samples, prototypes, and small series rapidly in an inexpensive way. To get the best deal, you should find a reliable manufacturing team to obtain your required Prototype Molding Services sans hassle.

To create a mold on any of the gaps between two tools, prototype molds can be a great help and it is chosen as per their work performance and color functions.

The use of prototype molding services-

Currently, many manufacturing teams are using prototype molding services for their projects to get rapid succession. It promotes promising results for the possible future. You should also realize that making molds is an art and it needs consistent expertise to optimize the best results. With the advent of technology and changes, this has become easier and smoother for the manufacturing team. The materials also can be handled with the development of different prototype mold and their functions.

Top 5 Tips to find the best prototype manufacturer-

It’s always great to create fresh new products for your market that appeal to the market. Therefore, it is important to test your products using building prototypes to make certain that the finished product comes out fast and right.

As we mentioned above, it requires professional expertise to produce the required parts by using a prototype molding process, you need to find a reliable and expert manufacturing team. In this article, you can find certain factors to be considered while choosing a manufacturing team for prototype molding services.

Start with small Orders-

When you are seeking a prototype manufacturing service provider for your projects, you should always start with small minimum orders. Especially, if you have a small-scale business, you ought to remain with your budget too. Make sure your manufacturing team can meet your needs, specifications, budget as well as meet your orders.

Tooling and Molding-

Make sure your custom manufacturing company could make your prototype as well as they should make tooling and molds to yield your products. A professional manufacturing team will lower your costs of investment that you can invest in the actual product development and marketing.

Quality of products-

A responsible prototype molding service provider should give quality assurance for the finishing and transport of your products. In this case, CNC manufacturing can significantly escalate the quality of your products.

Deadline-

A professional and expert prototype manufacturing team can able to finish your project within a deadline. No matter it is a prototype or final product, they can give fast turnaround times. Otherwise, you can meet and deliver the required products to your customers or users at the right time which can be a big loss to your business. Successful delivery of goods can contribute to the success of your business.

Bill of Materials-

The bill of the service should transparent which can help to grow a healthy relationship between a manufacturing team and a client. Make sure your prototype manufacturing team will help in the breakdown of costs of materials to show transparency on the materials utilized.

In a nutshell, when you are choosing a manufacturing team for prototype molding services, make sure they are reliable and consistent. They should be an excellent provider of a rapid prototype injection molding process for a wide range of applications across most major industry segments.

3ERP has years of experience in the rapid prototype injection molding process. Contact us for a free quote today.