The global aerospace industry is a hotbed of design and manufacturing innovation, with millions and millions of complex metal parts produced yearly.

An important tool at the aerospace industry’s disposal is CNC machining. Aerospace machining leads to advanced aircraft parts made from lightweight metals like titanium and aluminum, while machining is also a valuable prototyping tool for aerospace R&D departments.

Aerospace machining covers a range of applications too. Whether it’s commercial aircraft, military vehicles, or even space travel, CNC machining has a huge role to play in the development and production of precision aerospace components.

This articles serves as an overview of how CNC machining is used in the aerospace industry. It looks at aerospace CNC machining applications, aerospace machining materials, and more.

What is aerospace?

Aerospace is a highly diverse industry comprising many sub-sectors, covering everything from commercial aviation to space exploration. Its value as a global industry is estimated at around $800 billion.

Aerospace manufacturing involves production of parts for commercial, industrial, and military clients, with governments being some of the biggest contractors in the industry. In the United States, for example, the two biggest buyers of aerospace goods are the Department of Defense and NASA, the country’s aeronautics and space research agency.

Due to the vast number of aerospace sub-sectors and the vast number of applications and products within those sub-sectors, aerospace requires a broad range of manufacturing technologies, from traditional techniques like casting and welding to cutting-edge technologies like metal additive manufacturing. Aerospace CNC machining sits somewhere between those two extremes, being a highly established technology that nonetheless offers cutting-edge design and material possibilities.

What is aerospace machining?

Machining is the manufacturing process of removing sections of material from a workpiece using machine-operated cutting tools. And CNC machining is a digital version of machining: computers control motorized cutting tools to rapidly and precisely form new parts.

Aerospace CNC machining goes back almost to the invention of CNC machining itself, in 1942. One of the earliest applications of aerospace CNC machining was the production of bulkheads and wing skins. Today, many aerospace parts can be machined, such as transmissions, landing gear components, and electrical components. Machining might also be used to repair or modify existing parts, to add detailed features, or to add engraved textual information such as serial numbers.

Since many aerospace machining jobs involve the production of critical end-use components, precision machining is required with high-quality 5-axis machining centers. Certain parts — jet engine components, for example — may require tolerances as tight as 4 microns, far tighter than what is typically acceptable during CNC machining.

Aerospace machining is also an important form of prototyping during research and development. CNC machines are suitable for prototyping metal aerospace parts that will later be manufactured using casting or other techniques.

Aerospace machined parts

Aerospace machining is responsible for many aerospace parts, from vital titanium jet engine components to lightweight plastic interior cabin parts.

Parts that lend themselves toward aerospace CNC machining are typically low-volume parts that require high strength and fine features. Such parts are generally limited in size by the size of CNC machining centers, but several different materials can be used — usually titanium or aluminum alloys, but with other options like engineering plastics and composites also available. Some parts may be post-machined only, after being cast or extruded.

Aerospace machining can be used for prototypes and end-use parts. However, end-use parts must meet strict safety criteria, standards, and certifications.

Machinable aerospace parts include (but are not limited to):

- Landing gear components

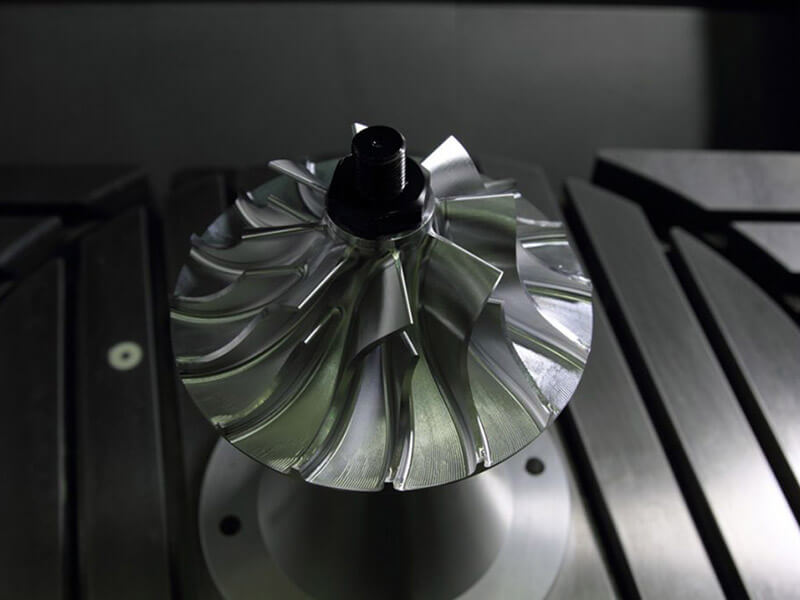

- Turbine blades and other jet engine components

- Engine housings

- Oxygen generation systems

- Filter bodies for liquid and air filtration systems

- Electrical connectors for electrical systems

- Motion controls

- Actuators

- Fuselage components

- Wing ribs

- Discs

- Shafts for power transfer

- Missile housings and other components

- Cabin parts

- Seating, armrests, and trays

Aerospace machining certifications

Aerospace CNC machining is a critical procedure that leaves no room for error. Where some industries allow for loose tolerances and material variations, aerospace demands total precision and consistency in order to guarantee human safety.

Different applications and parts must meet different standards and certifications, and there are some country-specific standards as well as international ones. However, one particularly important certification applicable to many applications is the AS9100 certification, an SAE international standard awarded to suppliers that is described as a “Model for Quality Assurance in Design, Development, Production, Installation, and Servicing” in aerospace.

An extension of ISO 9001, the AS9100 certification is not required for all aerospace part production, but customers may seek out suppliers with the certification to guarantee quality.

Other important certifications for aerospace machining include ITAR (International Traffic in Arms Regulations), a set of guidelines by the US State Department outlining US requirements for selling and producing technology on the US Munitions List, and AS9102 First Article Inspection Reports, which indicate compliance with the verification requirement aerospace parts.

Such certifications are not necessarily required for aerospace prototyping, since prototypes will not be used on active aircraft.

Aerospace machining materials

CNC machining is a versatile process that can be used to make components from both metals and plastics. In aerospace, however, two particular metals reign supreme: titanium and aluminum. This is due to the high strength (especially titanium) and light weight (especially aluminum) of the materials.

Titanium alloys

No industry worldwide uses more titanium alloy than aerospace. It’s easy to see why this is so: the metal has an excellent strength-to-weight ratio, resists corrosion, and performs to a high standard at extreme temperatures. Titanium has become a staple material in aerospace production, and its use will increase still further over the next century.

Aircraft that use large amounts of titanium for their various components include commercial vehicles like the AirBus A380 and Boeing B787, as well as military aircraft like the F-22, F/A-18, and UH-60 Black Hawk helicopter.

Titanium aerospace parts include airframe and jet engine components, such as discs, blades, shafts, and casings. Many of these can be machined.

Because titanium is harder than aluminum, it can be trickier to CNC machine, causing tool wear and heat buildup. This means aerospace machining of titanium may require a reduced machine RPM and larger chipload. (See our guide to machining titanium for more information.) However, since aerospace machining typically involves the most advanced and high-end machining equipment available, this is rarely an issue.

Aluminum alloys

Another widely used metal in aerospace machining — and one that has been around longer than titanium and modern composites — is aluminum.

Aluminum alloys are lightweight and have a high tensile strength. Aluminum forms an oxide coating when exposed to air, making it corrosion resistant, and it is also highly formable (more so than titanium), making it easy to CNC machine.

In aerospace CNC machining, the most common aluminum alloy is aluminum 7075, whose main alloying element is zinc. Though not as machinable as other alloys, 7075 has excellent fatigue strength. Many wing, fuselage, and support structure components are made from this material.

Other machinable aerospace aluminum alloys include 4047 (cladding/filler), 6951 (fins), and 6063 (structural). 6000-series alloys are generally considered more machinable than others.

Inconel superalloys

The Special Metals Corporation has developed a range of austenitic nickel-chromium-based superalloys called Inconel.

One particular grade of the material, Inconel 718, was developed specifically for aerospace applications. One of its first high-profile uses was for the jet engine diffuser case (an extremely high-pressure part that joins the compressor to the combustor) of the Pratt & Whitney J58 engine, which was used in vehicles like the Lockheed SR-71 Blackbird.

Inconel 718 has more recently been used by Elon Musk’s SpaceX in the engine manifold of its Merlin engine, powering the Falcon 9 launch vehicle. It is also found in other aerospace components like turbine blades, ducting systems, and engine exhaust systems.

As a work-hardened metal, Inconel 718 must be machined using as few passes as possible; machinists typically deploy an aggressive but slow cut using a hard cutting tool. The superalloy has good weldability, however.

Engineering plastics

In addition to metals like titanium and aluminum, aerospace machining can involve the use of high-performance plastics such as PEEK, polycarbonate, and Ultem.

Plastics can be a useful substitute for metals due to their very light weight, good impact and vibration resistance, sealing properties, and chemical resistance. They also offer superior electrical insulation to metals.

Aerospace CNC machining of engineering plastics can produce aerospace parts like cabin interiors, tray tables, arm rests, housings, wear pads, insulation, tubing, valve components, and back-lit instrument panels.

An important consideration is that aerospace plastics must meet specific flame, smoke, and toxicity requirements. Suitable materials include Nylon (certain grades including Nylon 6), PEEK, Ultem, and PPS.

3ERP is a CNC machining specialist with experience working with customers in the aerospace industry. Contact us for a free quote.