Manufacturing processes are vital to meet demand for various consumer goods. Evolving technology and computing is rapidly changing the manufacturing scene. Manufacturers and professionals in the industry often query about the different processes available for them.

This article will have an in-depth discussion on ‘what is manufacturing process?’ You will learn about the basics of manufacturing, the various types of manufacturing processes, strategies, and many other useful information.

What is Manufacturing?

Manufacturing is the process of transforming raw materials or components into finished goods through various equipment, methods, techniques and processing.

The goods can be either for consumer demand or industrial use. Manufacturing processes use many different types of tools and machinery to accomplish the purpose. It is usually done in multiple stages, starting with raw material sheets or blocks.

Example of Manufacturing Processes

Everything around you is a result of manufacturing processes. For instance, smartphones are manufactured in large-scale production line. Every part of the smartphone is a result of a separate manufacturing process. The screen is manufactured in a separate facility. The motherboard it uses comes from semiconductor manufacturing processes. The body is a result of CNC machining.

History of Manufacturing

The evolution of manufacturing processes goes hand in hand with the evolution of civilization. With time, additional materials found usage in the manufacturing processes. Copper, Bronze, and Iron became the standard materials for use in tools, pottery items, weapons, and other products. Manufacturing methods evolved with the growth in possible materials.

The most rapid growth of manufacturing processes occurred in the industrial revolution. Processes traditionally done by hand transitioned to machinery. Technology like steam power and electricity further fueled the drive toward manufacturing innovations.

The development of computers led to the emergence of Computer Numerical Control (CNC) technology. It added the element of automation to the manufacturing industry. Modern manufacturing businesses use advanced machinery with highly automated operations for mass production.

What are the Different Types of Manufacturing Production Processes?

Production processes can be classified into three types of classes. These classes are:

Make to Stock (MTS)

Make to Stock (MTS) is one of the traditional manufacturing techniques. In MTS manufacturing, products are manufactured anticipating the potential demand. The manufactured products are then stored in inventory.

In the Make to Stock (MTS) strategy, manufacturers can use prior sales to estimate the production volume. Estimates can also be based on market research. The customers get the product instantly when desired. This is why Make to Stock has been the go-to manufacturing technique in the past.

Advantages of Make to Stock

Make to Stock provides the advantage of the shortest lead time. The products are ready before the customer demand. Therefore, the customers don’t have to wait at all for the product.

Disadvantages of Make to Stock

A main disadvantage of Make to Stock is the high upfront costs. Large-volume production beforehand requires a large investment. Additionally, there is the risk of products going unsold. This brings in the idea of losses.

Application

The clothing industry is a good example of a manufacturing business using the MTS method. Brands manufacture clothes in large-scale production to meet customer demand. If the products are left unsold, stores offer discounts so new orders can be stocked on the shelf.

Make to Order (MTO)

Make to Order (MTO) manufacturing starts production once the customer places the demand. This eliminates the shortcoming of the Make to Stock method. There are no large upfront production costs and no risk of products going unsold.

Advantages

The manufacturing business does not require a large product inventory in the Make to Order model. After manufacturing, products are sent to the delivery phase immediately. This saves up inventory management costs. However, there still needs to be an inventory of the parts required for manufacturing.

Disadvantages

A major shortcoming of the Make to Order model is the high lead time. Production begins once the customer demand comes in. Therefore, the customer has to wait for the product. However, it provides the benefit of incorporating customer feedback into the production phase.

Application

A major application of Make to Order is the manufacturing of defense equipment. The production starts once the customer has placed the order. In this way, manufacturers can also take customers’ requirements into account. Additionally, there is no risk of products becoming obsolete.

Make to Assemble (MTA)

In the Make to Assemble (MTA) model, the subparts of a product are manufactured beforehand. However, product assembly takes place after the customer orders the product. It is also known as Assemble to Configure (ATC) or Configure to Order (CTO).

Advantages

Make-to-Order combines some of the benefits of Make-to-Supply and Make to Order. Since the component parts are manufactured beforehand, the waiting time after customer orders is quite short. Additionally, the product can be customized to meet specific consumer demand. The customer can tailor the product as per their preference.

Disadvantages

Make to Assemble also carries some of the disadvantages of the two earlier manufacturing models. Pre-manufacturing of component parts requires a huge initial investment. Additionally, assembly is done after the customer orders the product. Therefore, there is still some waiting time involved.

Application

A good example of Make to Assemble services is the laptop manufacturing model. Manufacturers store an inventory of component parts like memory, body, storage, screen, and many other things. The parts are then assembled in many different ways to meet demand of separate customers.

What are the Different Manufacturing Methods?

Many different types of manufacturing processes are available to achieve different results. Some of these manufacturing processes are:

Forming

Forming processes change the shape of the material without cutting it. This process is based on the plastic deformation of materials. It has a limited range when it comes to applicable materials. This is because not all materials have plastic deformation properties. For instance, if you try to bend glass, it will break.

Forming has low manufacturing costs and negligible material wastage. Forming commonly applies to manufacturing metal products. However, it cannot create unique features or internal geometries in the products.

Common examples of forming manufacturing processes are:

- Forging

- Extrusion

- Thread Rolling

- Bending

- Stamping

- Rolling

Application of Forming

Forming is used for a wide range of metal and alloy products. Common examples of forming are:

- Pipes

- Turbine rings

- Metal plates

- Sheets

- Automobile frames

Casting

Casting melts the material and pours it into a mold of the required product. When the material cools off, the final part is formed. Casting process can make shapes of varying complexity. Casting is one of the oldest manufacturing methods initially used for making metal coins and sculptures.

Casting is one of the cheaper manufacturing methods. However, it only works for materials that can be melted and turned into the desired shape. Therefore, it is mainly used for metals and some plastics.

Common applications of casting manufacturing processes are:

- Mining equipment

- Automotive industry

- Defense parts

- Art and sculpture projects

- Household fittings

Joining

The joining manufacturing process is used to fuse two different parts together. It is used during the manufacturing of complex products. Directly manufacturing a complex product can be unfeasible at times. Therefore, the production is divided into manufacturing multiple simple parts and then joining them together.

Joining can lower the production costs involved with manufacturing complex parts. There are instances where joining is the only feasible way of manufacturing a product. Joining also provides the benefits of replacing a portion of the product during a fault instead of an entire product replacement. Some examples of joining processes are:

- Soldering

- Brazing

- Nut bolt fasteners

- Knuckle joints

- Adhesive bonding

- Resin bonding

- Knuckle joint

- Cotter joint

Most consumer goods are formed with joining manufacturing processes. For instance, electronic items use joining for fusing countless smaller components together. Examples of joining manufacturing process are:

- Electronics appliances

- Aircraft

- Automobiles

- Smartphones

- Furniture

Molding

Molding is similar to the casting manufacturing process. In molding, the molten material is poured into a negative impression of the final product. The negative impression is called the mold. While casting mostly applies to metal, molding makes plastic parts.

Molding requires a high initial cost for making the molds. The lead time for production is also high. However, once the molds are created, the process applies to mass production. The molds can be reused, lowering production costs.

Some common types of molding processes are:

- Injection molding

- Compression molding

- Extrusion molding

- Transfer molding

- Thermoforming

- Reaction injection molding

- Crown molding

Molding has extensive applications in consumer products, such as:

- Packaging for food products

- Medical parts

- Automotive industry

Additive Manufacturing

The additive manufacturing process creates a product by adding material layer by layer. The material is deposited with the application of heat. The layering process is generally controlled by automated software programming.

The additive manufacturing process works on materials that are moldable by heat. This includes metals and certain plastics. Additive manufacturing processes have a high degree of customization. The lead time for these processes is short. However, the manufacturing time can take longer.

The various types of additive manufacturing processes are:

- 3D Printing

- Directed Energy Deposition

- Binder Jetting

- Material Extrusion

- Sheet Lamination

- Powder Bed Fusion

- Vat Polymerization

The additive manufacturing process has a lot of applications in the manufacturing business. Some of these applications are:

- Jewelry making

- Medical implants

- Special machinery gears

- Automobiles component parts

- Robots

Subtractive Manufacturing

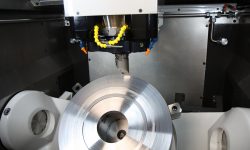

Subtractive manufacturing handles part creation by the controlled removal of materials. Subtractive manufacturing is also known as machining. It is the most versatile process that works on every type of material.

Machining processes are controlled by Computer Numerical Control (CNC) technology. It provides automated movement of tooling along with high speed and precision. Subtractive manufacturing processes are the dominant technology for most manufacturing industries. Most job shop manufacturing businesses use machining technology.

Some common subtractive manufacturing processes are:

- Milling

- Reaming

- Drilling

- Turning

- Boring

- Electrical Discharge Machining

- Waterjet Cutting

Different Types of Manufacturing Strategies and Approaches

Manufacturing process of a part can be done in a lot of different ways. These approaches have varied requirements, applications, and results. The different manufacturing strategies are:

Repetitive Manufacturing

Repetitive manufacturing is the large-scale production of smaller component parts that later go for assembly. Repetitive manufacturing has a rigid assembly line for ultra-fast production speed in large volumes. There is no customization in this manufacturing technique to meet the production time frame.

The fast production speed requires raw materials to be stacked next to the production line. The production routing of repetitive manufacturing is not complex. The finished products are sent for later use in batches when produced.

On-demand Manufacturing

On-demand manufacturing process is heavily based on customization. The production is done in small batches after receiving customer orders. The customers can specify the product specifications they require. This production model requires a low initial investment. Customers often provide part of the payment in advance.

The on-demand manufacturing sector has the drawback of long lead times. An order goes into production only after customers place their order with requirements. Therefore, the production time of this process can be very long.

Custom Manufacturing

Custom manufacturing is intrinsically linked to specificity. This mode of production is centered around unique customer specifications, often involving one-off or limited runs of a particular product. The customers dictate the exact parameters for the product, ranging from design to functionality.

The initial investment is typically moderate, given that production kicks off only after an order is confirmed. Pre-payment is usually part of the transaction process.

However, custom manufacturing is not without its challenges. Given its reliance on individual orders, the lead time for each product can be extensive.

Manufacturing only commences once an order is placed and detailed specifications are provided, which can result in significant delays in delivery time.

Assembly Line Manufacturing

The assembly line manufacturing process uses the finished products from repetitive manufacturing. It is a quicker manufacturing process because only the joining of various components is required.

Assembly lines were the driving force behind the industrial revolution. Most mass production industries use the assembly line model. After products are created in the assembly plant, they are shipped to the customers. There is usually no post-processing required after the assembly stage.

Discrete Manufacturing

Discrete manufacturing involves the manufacturing of identifiable products different from one another. It also tracks the raw materials that go into making a product. Any variations in the product can be made quickly. The production line of cars is a good example of discrete manufacturing. On the other hand, the production of cooking oil follows non-discrete manufacturing because each unit product is not distinct.

Job Shop Manufacturing

Job shop manufacturing involves production in a small workshop area. There is no assembly line in this production. Job shop manufacturing applies to the production of low-volume products. These products are generally custom orders based on client-specific requirements. This production model is common for making machinery for other industries. It is also used for making specialized aircraft and marine industry niche parts.

Mass Production

Mass production involves the manufacturing of a standard product in very large volumes. This manufacturing model can use several processes and technology to meet the production numbers. Modern mass production lines involve heavy use of automation and robots. Due to heavy automation, a mass production line has a dedicated quality control and inspection area.

Continuous Process Manufacturing

Continuous process manufacturing works 24×7 without any interruptions in the manufacturing process. This manufacturing approach applies to flowable products. Common examples of continuous process manufacturing are oil refineries, gas plants, electricity generation, water treatment facilities, etc.

The machinery used in continuous process manufacturing runs around the clock. The processes are all consistent without any variations in them. This process is the opposite of batch process manufacturing.

Batch Production Manufacturing

Batch process manufacturing involves production in a limited number. Production is halted after the production numbers are met. Production is resumed again after a period of pause. The amount of products produced usually depends on the customer’s order.

The products in a batch are highly consistent. However, there can be variations between two different batches. The waiting time between batches provides an opportunity for quality control and machinery testing. Additionally, it provides an ease of inventory management and utilization.

Lean Manufacturing

Lean manufacturing involves focusing on maximum productivity and generating minimal waste. Waste includes more than just the materials not used. Waste includes any activity or products that the customer will not pay for. Lean manufacturing aims to bring down these redundant products and processes. By doing this, the lean manufacturing process increases production quality while decreasing lead times.

Green Manufacturing

Green manufacturing is the production process that focuses on environmentally friendly processes and materials. The processes in green manufacturing emit minimal pollution levels. The materials are usually reusable. Most of the waste generated in a green manufacturing process gets recycled.

It can take some investment to shift from conventional manufacturing to a green manufacturing option. However, green manufacturing processes can be cost-saving in the long run. Additionally, more and more consumers are seeking green manufacturing alternatives.

Process Manufacturing

Process manufacturing involves a large-scale production line based on a single recipe. The products created with the process manufacturing process are indistinguishable. Therefore, process manufacturing can be considered the opposite of discrete manufacturing. For instance, a butter manufacturing facility can be considered a process manufacturing sector. Similarly, juice production lines are also part of the process manufacturing industry.

Multiple process manufacturing industries can be combined to become a discrete manufacturing plant. For instance, butter is a process-manufactured product. Similarly, cardboard packing of butter is also process manufactured. However, these two assemble to become discrete manufactured products.

Smart Manufacturing

Smart manufacturing involves production using computational intelligence. The smart manufacturing process is a great way to handle inventory management. Smart manufacturing can also adjust the production process to meet demand efficiently. Features such as smart simulations help predict problems in the assembly line before they occur.

Smart manufacturing techniques can be integrated with every other manufacturing method. This integration enables the manufacturing industry to save costs and increase productivity using data analytics. Additionally, smart manufacturing techniques can also eliminate bottlenecks in production systems.

What are the Different Manufacturing Industries?

There are many different types of manufacturing industry. Each industry has its dedicated setup and preferred manufacturing strategies. These different manufacturing industries are:

Automotive Manufacturing Industry

The automotive manufacturing sector is one of the largest in the world in terms of revenue. For instance, manufacturing industries like Toyota Motor Corporation is the world’s second highest revenue manufacturing industry.

The sector’s high demand and revenue enable automobile makers to use the most innovative technologies and processes. Modern manufacturing of automobiles utilizes hybrid manufacturing models for exceptional quality control.

Aerospace Manufacturing Industry

Aerospace manufacturing industries require one of the most innovative manufacturing technologies. Aerospace industries create equipment that needs to handle the toughest conditions. Therefore, every part is based on custom specifications to meet the highest standards of the aerospace sector.

Defense Manufacturing Industry

The defense industry works similarly to the aerospace sector. Defense parts require tough metal alloys and innovative materials to withstand field conditions. Defense manufacturing industries generally utilize the on-demand manufacturing model with high customization.

Machinery Manufacturing Industry

Machinery manufacturers supply tools and equipment to other industries. These industries deal with custom orders to fulfill the client’s manufacturing setup. These equipment are produced in very limited quantities. This eliminates the scenario of obsolete inventory due to evolving technologies.

Electronics Industry

Electronics manufacturers combine mass production methods with an assembly line setup. Smaller parts like PCBs, semiconductor setups, processors, displays, etc. are created in their own production line. Assembling then takes place in a later phase at the manufacturer’s facility.

Food Products

Food products are generally manufactured in a continuous process manufacturing setup. Large inventories of raw materials are kept in stock. The produced items are then assembled with the food packaging products. The finished items are output in a batch process manufacturing setup.

Textiles

Textiles are generally manufactured in a large-scale production line. The finished products are shipped to stores instead of saving in inventories. Older products are often sold at a discount to make room for new inventories.

Chemical Processing and Manufacturing

The chemical processing industry converts raw materials to products such as bleach, oil, cosmetics, floor cleaners, etc. These industries generally operate in process manufacturing industries. The finished chemicals are then packed in dedicated containers in later assembling. The process then incorporates the batch production method.

Pharmaceuticals Industry

Pharmaceuticals are one of the biggest manufacturing industries. It creates medicine, vaccine, and other medical products. The pharmaceutical sector works similarly to the chemical processing plants. The products in the pharmaceuticals sector are manufactured well before consumers demand them. There is a major risk of product expiry in this sector.

Construction Materials Manufacturing

The construction materials manufacturing business works with making and processing concrete, lumber, bricks, and other raw materials. The manufacturing model of this sector is very varied. It depends on the project, the consumer, and the particular order quantity.

Metal Fabrication

Metal fabrication sector works with the processing of metal raw materials for use in secondary sectors. The metal fabrication sector meets the requirements of automotive, agricultural, industrial machinery, aviation, and many other industries. Metal fabrication can work in job shop manufacturing models or larger-scale production lines.

Plastics Manufacturing

Plastics manufacturing business usually employ processes like molding. Plastics are directly formed into the final shape required. Plastics that can change shape with heat can work well with additive manufacturing technologies like 3D printing.

Furniture Making

Furniture-making industries have varied production methods based on the scale of the industry. Smaller industries may employ job shop manufacturing and on-demand manufacturing model. In this way, they can adjust the production volume according to market demand. It also helps in inventory management.

Manufacturers on a larger scale may employ batch production to have readymade orders before the market requires them. However, the production volume is limited due to shifting market trends and the required capital.

Paper Manufacturing

Paper manufacturing business produces a diverse range of products. Common output products of this industry are newspapers, notebooks, books, cardboard, decorations, and many other paper-based items. These facilities can use batch production or process manufacturing facilities. The technology is usually simple due to lesser variation in the types of component parts.

Energy

The energy sector produces fuels and fuel-based products. Oil and gas industry is a good example of this sector. These are manufactured in a process production facility. Energy sector uses complex and innovative machines to withstand the tough conditions of deployment.

Steps in the Manufacturing Process

In general, the manufacturing setup follows a similar sequence of events. These events are:

1. Envisioning the Product

Firstly, the manufacturer shortlists the product they want to manufacture. This involves having a general idea of the product. It is not mandatory to have the exact product features in mind at this stage.

2. Product Research

Product research begins once the manufacturer has a basic idea of the product. The product features can be listed in this stage. Manufacturers also look for competing products and analyze the market demand. A business plan helps in outlining the manufacturing number and scaling strategy. Various product materials are shortlisted at this stage.

3. Product Design

The product is materialized into engineering graphical designs. The designs take into account the dimensions of each product feature. It also finalizes the product material and any other query for the product. The product then goes into the prototyping stage.

4. Prototype Testing

`Prototype testing involves making models of the product. The models are ideally as identical to the product as possible. The prototype gives the manufacturer an idea of what the product will look like. Any major issues with the product are fixed at this stage.

5. Product Manufacturing

A limited manufacturing run of the product starts when the prototyping stage finishes. These manufactured units are for the end customers. The manufacturers collect feedback from the customers about their experience with the product.

6. Feedback Loop

The feedback from customers is incorporated into the product. The updated part is then manufactured with the new changes. The customers can provide feedback on the new changes as well. The feedback loop continues for a few iterations till the product is perfected.

7. Official Release

The final product is released officially to the mass market. In this phase, there are no limits on the production numbers. The production is done in numbers that can fulfill the customer demand.

Advantages and Disadvantages of Manufacturing Industry

There are many benefits and some limitations to the manufacturing sector. These are:

Advantages of Manufacturing

- Scalable sector

- Very profitable

- Flexible

- Adjustable investment

Disadvantages of Manufacturing

- Constantly evolving

- Dependent on supply

- Operational costs

Risks in Manufacturing

Manufacturing is done taking into account certain risks. Some of the risks associated with manufacturing are:

Intellectual Property Theft

Intellectual Property theft is a common issue in manufacturing. It occurs when the design or recipe of a product gets stolen by another party and manufactured under a different name. This can mean losses for a manufacturer for a product that they designed themselves.

Product Recalls

There are instances when a significant flaw in the product gets unnoticed. This leads to product recalls by the manufacturer. Product recalls can be very expensive and lead to major losses.

Supply Chain Interruption

Supply management is crucial once the product is released to consumers. However, there are many risks of supply chain interruptions. For instance, transportation can get delayed. There can be shortage of a particular raw material. A machine can face a breakdown. These supply chain interruptions can cause delays which translate to financial losses. It may also come with a loss of business.

Raw Materials

The price of a product is based on the prices of raw materials during product design. However, these prices can increase at a later time without prior notice. Manufacturers don’t have the freedom to adjust product prices so freely. This can lead to instances where manufacturing costs exceed product selling points.

Outdated Techniques

Manufacturing technologies evolve at a rapid pace. Manufacturers don’t always have the investment to adapt to evolving technology. Industrial machinery is highly expensive. Updating the equipment regularly leads to unaffordable expenses for the manufacturers.

Major Challenges Manufacturers Face In Today’s Business Environment

There are certain challenges that today’s manufacturers face in most sectors. These challenges are:

- Competition: There is significant competition in every manufacturing sector. This means that manufacturers must spend extra to improve product features and market that product.

- Environmental Concerns: Manufacturing involves a certain level of carbon footprint. Some sectors are more hazardous in this regard than others.

- Cyberattacks: Modern businesses rely on IT systems to store data. This brings in the risks of cyberattacks. Data breaches due to cyberattacks cause tremendous losses and business closures.

- Workforce Development: Manufacturers must invest more to hire a skilled workforce. In the shortage of skilled workforce, they have to invest in workforce training.

- Regulatory Compliances: Most manufacturing sectors work under regulatory compliances. These compliances can be related to the quality control of the final product, workplace conditions, or data security.

Important Factors in the Manufacturing Process

There are certain factors on which every manufacturer must focus for the optimal process. These factors are:

- Product Quality: The product should have acceptable quality standards. Otherwise, the manufactured product is considered rejected. It can lead to a loss of reputation or financial losses for the brand.

- Production Costs: Products have a preset value in the market. Manufacturers ensure that the production costs fall well below this value to remain profitable.

- Modularity: The manufacturing system should have enough flexibility to meet with any variations in the supply. It can be due to changing demand or due to new required variations in the product.

- Efficiency: All the waste generated in the manufacturing process is potentially a loss. Manufacturers aim to bring down waste for maximized efficiency. Waste includes unwanted material, parts, and idle labor.

- Safety: It is important to ensure the safety of the workforce and the workplace. Workers require a safe environment to work in. Safety is achieved with protection measures in the equipment and processes.

- Product Marketing: Marketing is very crucial in today’s business environment. Manufacturers have to market their product to stand toe to toe with the competitor.

What is Manufacturing Cost?

Manufacturing cost is the investment that goes into manufacturing a product. The cost is the price of raw materials, labor wages, utilities, etc. The primary cost is the price of raw materials and labor used during the manufacturing of the product directly. These are called operational costs.

There are also added costs of materials and utilities not consumed directly by the product. These indirect costs are termed manufacturing overhead. Production costs are easy to calculate. However, manufacturing overhead calculation can be more complex.

How to Calculate Manufacturing Overhead?

Calculation of manufacturing overhead can involve several factors such as:

- Maintenance of Equipment

- Repairs

- Finance and mortgage

- Insurance

- Waste Management

- Indirect supply materials like lubricant, coolant, adhesives, cleaners, etc.

The Future of Manufacturing

Manufacturing processes have been evolving since their initiation. The future holds even more complex technologies for manufacturing. Some of the things to look out for are:

- Internet of Things (IoT): IoT is changing the way modern products are manufactured. Machines can now provide feedback data to the loop that eliminates bottlenecks and improve efficiency.

- Robotics: Robots are taking over the assembly lines for automated production. This ensures faster production and round-the-clock operations without breaks.

- Sustainable Manufacturing: Sustainable manufacturing aims to use environmentally friendly raw materials and processes. This reduces the adverse effects of manufacturing processes on the ecosystem.

- Artificial Intelligence (AI): AI is improving manufacturing by estimating demands, increasing the customer base, and predictive maintenance of equipment.

Conclusion

The information provided above gives a detailed analysis of what is manufacturing and why it is important. You now know the various manufacturing methods and how they work to process raw materials. Due to the rapid innovations in the industry, staying on top of the latest manufacturing technology can give you a great edge over your competitors.

Frequently Asked Questions

Here are the answers to some common questions regarding manufacturing:

1. Is manufacturing a good business?

Yes, manufacturing is a great business. The manufacturing sector supports every other business directly or indirectly. Therefore, there will always be demand for the manufacturing industry.

2. What are the main goals of manufacturing industry?

The main goal of the manufacturing industry is to create products that customers and other businesses will pay for. The products are made of acceptable quality with preset specifications and processes.

3. What is the difference between manufacturing and production?

Manufacturing is the creation of tactile goods by processing of raw materials. Production is a wider bracket that includes creation of anything of value. This can be products, goods, raw materials, or even services. Therefore, steel manufacturing process can be a production process. However, software making is a production method but not a manufacturing process.