Metal Parts Fabrication Guide

Everything You Need to Know

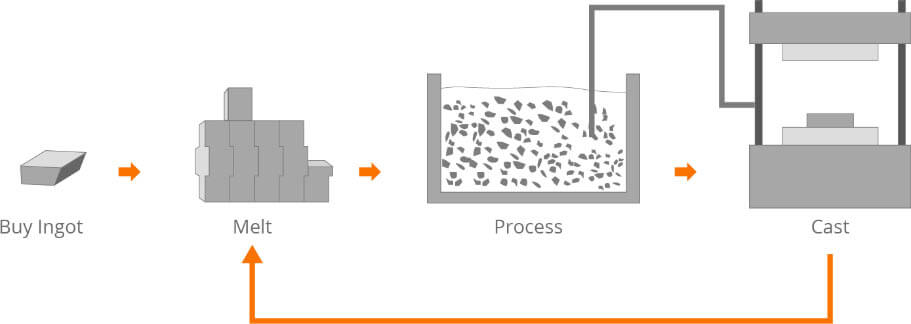

Casting

The method of producing blanks or parts by pouring liquid metal into a moulding cavity having a shape identical to the shape and size of the part and leaving them to cool down for solidification, is generally called the forming or casting of liquid metal.

Processing flow: Liquid metal –> mold filling –> solidification & contraction –> casting

Processing characteristics:

- Being able to produce any piece with complicated shapes, especially in cavity

- Strong adaptability, unlimited categories of alloy, non-restricted size of casting

- Wide source of materials, scraps that can be re-melted, low cost in equipment.

- High proportion of scraps, low surface quality, poor labor condition.

Casting category:

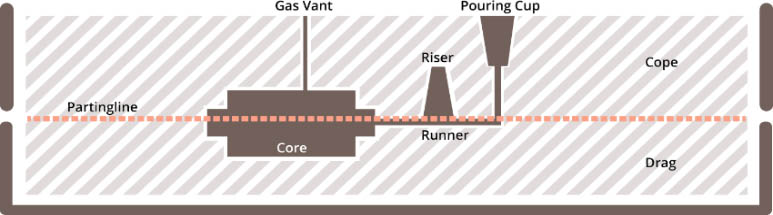

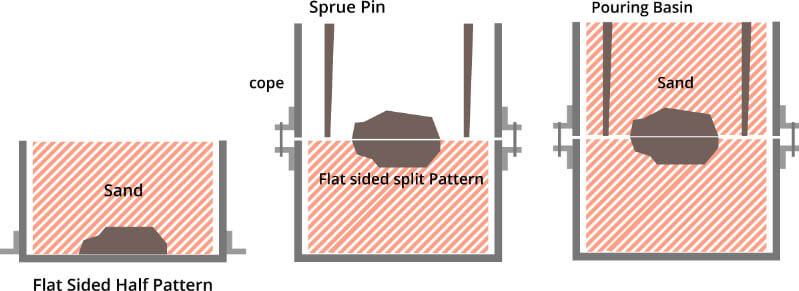

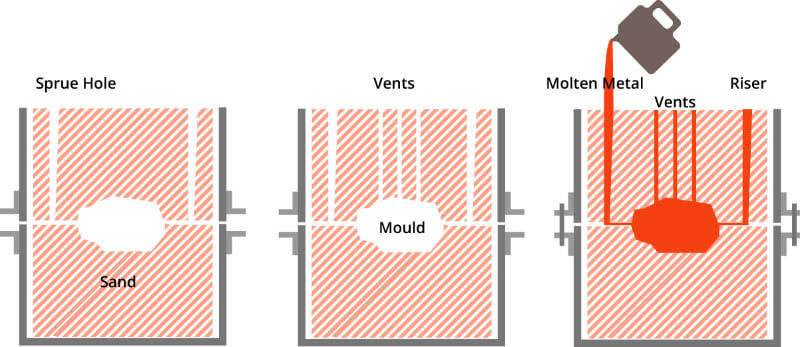

Sand casting

A method of producing casting in sand molds. Steel, iron and most nonferrous alloy castings can be obtained via sand casting method.

Processing flow:

Technical features

- Suitable for making blanks with complicated shapes, especially in cavity

- Wide adaptability with low cost.

- For some materials with poor plasticity, such as cast iron, sand casting is the only forming process for making the parts or blanks

Application: Engine cylinder block, cylinder head, cranks and other castings used for automobiles.

Investment Casting

Investment Casting

A casting scheme, which is often called “dewaxing casting”, that uses fusible material to make a pattern, on which several layers of refractory material are applied to produce a shaping shell, from which the pattern is melted to obtain an integral casting mold that will be baked at high temperature and can be used for casting via sand filling.

Processing flow:

Processing advantages

- High precision in size and geometry.

- High surface coarseness.

- Be able to produce castings with complicated external forms without limitation to the cast alloy.

Processing disadvantages

1. Complicated procedures and higher cost.

Applications Applicable to produce small parts with complicated contours and high precision, or that cannot be manufactured in other ways, such as blades of turbo engine.

Die Casting

Die Casting

Metal liquid under high pressure is pressed at high speed into the cavity of a precise metallic mold, in which the metal liquid under pressure is cooled down and solidifies into the casting.

Processing flow:

Processing advantages

- High precision in size and geometry.

- Good product quality, stable size and good interchangeability.

- High productivity and more life cycles of die.

- Suitable for batch production, good economic benefit.

Processing disadvantages

- The castings tend to have fine air pores and shrinkage porosity.

- Die casting is characterized with low plasticity and not applicable to working conditions subject to impact load and shock.

- In die casting of high melting point alloy, the die has a shorter service life, which restrains the expansion of die-casting production.

Application Die casting was initially used for the automobile and instrument industries and then spread to other sectors, such as agricultural machinery, machine tool, electronics, national defense, computer, medical devices, watches and bells, camera and daily hardware.

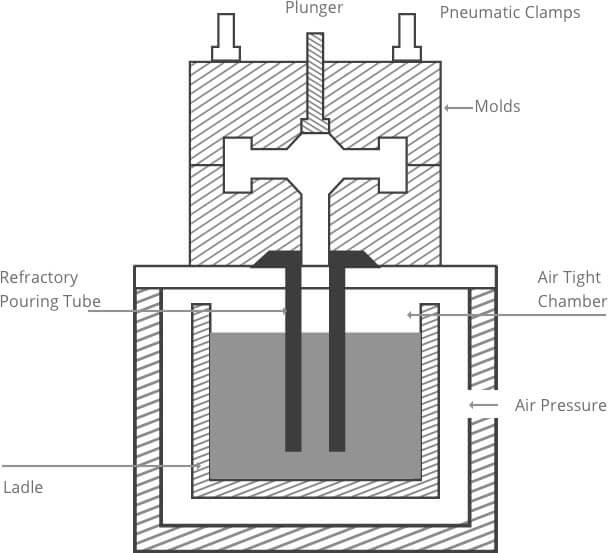

Low Pressure Casting

Low Pressure Casting

It is a method of producing casting via crystallization under pressure after liquid metal is filled in the die mold under a relative low pressure (0.02~0.06MPa).

Processing flow:

Technical features

- Pressure and speed are adjustable during casting. Hence it is applicable to a variety of casting molds, such as metal mold and sand mold and can be used to cast various alloys and to produce castings in different sizes.

- With bottom filling method, metal liquid is filled smoothly without splashing, which avoids penetration of air and flushing to the walls and cores, thus improving the conformity of castings.

- The casting crystallizes under pressure. It is densely structured with clear profile, smooth surface and high mechanical property. This is especially beneficial for thin-wall castings.

- By omitting the feeding head, the utilization of metal has been raised to 90-98%.

- Low labor strength, better labor conditions, simple equipment and that it is easy to achieve mechanisation and automation.

Application It is mainly focused on traditional products (cylinder head, hub and cylinder rack).

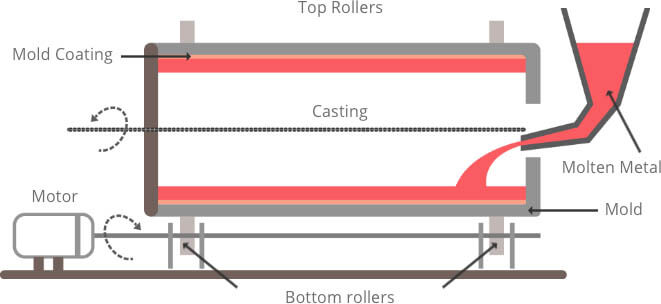

Centrifugal Casting

Centrifugal Casting

A method of pouring metal liquid into a rotating casting mold so as to fill the mold with centrifugal force and solidify the metal into desired shapes.

Processing flow:

Processing advantages

- There is barely consumption of metal in the pouring system and the feeding-head system, which improves productivity of the process.

- Mold core can be omitted in making of a hollow casting. Therefore, the metal-filling capability can be considerably improved in manufacture of long tubular castings.

- The resulted casting is featured with high density and mechanical property almost without porosity and inclusions.

- It is useful for making sleeve or bushing-like composite metal castings.

Processing disadvantages

- It is somehow limited in manufacture of special-shaped castings.

- Inaccurate bore diameter of casting, coarse internal surface, bad quality and larger machining margin.

- It is easy for the casting to have gravity segregation.

Application Centrifugal casting was used for producing cast tubes in early time. It is used to manufacture steel, iron and nonferrous carbon alloy castings used in the metallurgy, mining, traffic, drainage and irrigation machinery, aviation, national defense, automobile and other industries. It is most commonly used for manufacturing castings such as centrifugal cast tubes, cylinder liners and shaft sleeves used for internal combustion engines.

Gravity die casting

Gravity die casting

A method of forming castings by filling a metallic mold with liquid metal under gravity and solidifying it in the mold.

Processing flow:

Processing advantages

- Metallic molds have a higher heat conductivity and capacity, rapid cooling down, dense casting structure, and its mechanical property is about 15% higher than a sand casting.

- Be able to obtain a casting with higher precision in size and lower value in surface roughness, in addition to good consistency of quality.

- As sand core is not or seldom used, it is able to improve the environment, reduce dust and harmful gases, and decrease labor strength.

Processing disadvantages

- As the metallic mold is airtight, measures must be taken to direct air out of the mold cavity and the gases out of the sand core.

- As metallic mold is non-flexible, it tends to have cracks during solidification of casting

- Metallic molds are subject to a longer manufacturing cycle and higher cost. Therefore, better economic effects can be demonstrated only in batch production.

Application Metallic mold is applicable to batch producing either nonferrous alloy castings, such as aluminum alloy and magnesium alloy parts with complicated shapes, or steel and iron castings or ingots.

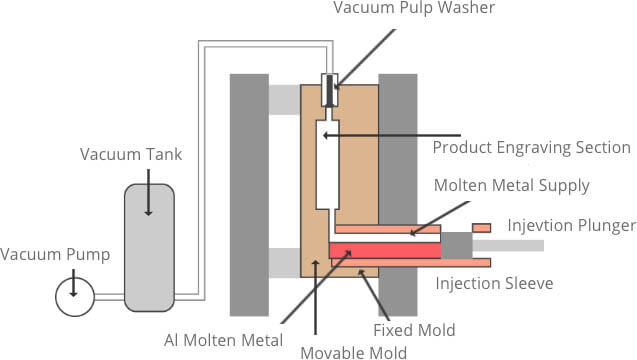

Vacuum die casting

Vacuum Die Casting

An advanced die casting process that is used to improve the mechanical property and surface quality of casting by removing gas from the die casting mold cavity or considerably reducing the porosity or dissolved gas in the casting.

Processing flow:

Processing advantages

- Eliminate or reduce porosity inside the casting, improve mechanical property and surface quality of the casting as well as the coating performance.

- Reduce counter pressure in mold cavity; alloy with lower specific pressure and poor casting performance can be used; it is possible to manufacture larger casting with small machine.

- With improved filling condition, it is possible to make thinner casting.

Processing disadvantages

- Mold seal is complicated in structure and it is hard to manufacture and install. As a result, the cost is relatively high.

- Vacuum die casting may not render considerable effect if inappropriately controlled.

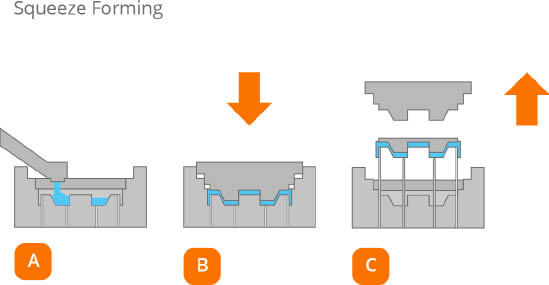

Squeezing Die Casting

Squeezing die casting

A method of directly obtaining the part or blank from liquid or half-solid metal that solidifies or flow to form under high pressure. It is a metal-forming technique with potential prospect for application due its high liquid metal utilization, simplified procedure and stable quality.

Processing flow:

Direct squeezing die casting

coating spray, pouring alloy, mold closing, pressurizing, pressure keeping, pressure releasing, mold opening, blank demoulding, reset.

Indirect squeezing die casting: Coating spray, mold closing, feeding, filling, pressurizing, pressure keeping, pressure releasing, mold opening, blank demoulding, reset.

Technical features

- Internal air pores, voids and shrinkage porosity can be eliminated

- Low surface roughness and high precision in size.

- Cracks caused by casting can be prevented.

- It is easy to achieve mechanization and automation.

Application It can be used to produce a variety of alloys, such as aluminum alloy, zinc alloy, copper alloy and nodular cast iron.

Lost foam casting

Lost foam casting also known as full mold process. An innovative casting method that uses wax or foam models in a shape and size similar to the casting to form a group of models via bonding, which are applied with refractory coating and then dried with heat, buried in dry quartz sand to form via vibration, and that liquid metal is poured under negative pressure to gasify the models so that liquid metal takes the position of model, and cools down and solidifies to form the casting.

Processing flow:

Pre-foaming -> Foam molding -> dipping in paint arrow-right drying -> shaping -> pouring -> shakeout -> clearing

Technical features

- High casting precision without sand core, which reduces the processing time.

- Integrated mold surface, flexible design and high freedom.

- Clean production without contamination.

- Reduction of investment and production cost.

Application It is suitable for production of precise castings with complicated structure, in various sizes, without limitation to alloy species and batches of production, such as gray pig iron engine housing and high manganese steel elbow.

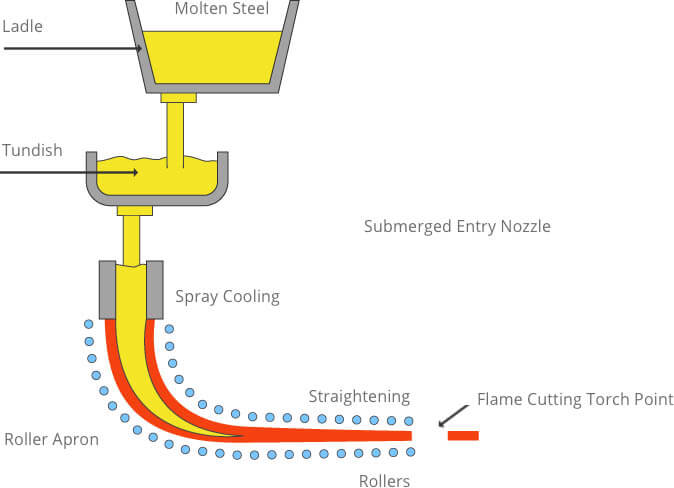

Continual Casting

Continual Casting

Continual Casting This is an advanced casting method. Its principle is that molten metal is continuously poured into a special metallic mold called crystallizer, from which the solidified (skulled) casting is continuously pulled out from the other end of the crystallizer, and it is possible to obtain a casting with any or certain length.

Processing flow:

Technical features

- Since metal is cooled down rapidly, the casting is characterized with dense crystallization, uniform texture and good mechanical property

- Less metal and higher yield.

- Simplified procedure and exempted shaping and other procedures have reduced the labor strength; the desired area for production is also reduced considerably.

- Continual casting production makes it easy to realize mechanization and automation as well as improvement of productivity.

Application Continual casting method can be used to cast steel, iron, copper alloy, aluminum alloy and magnesium alloy into long castings with consistent form of section, such as ingot, plate blank, stick blank and pipe.

Forming

Plastic forming: It is a method of using the plasticity of material to manufacture a part with the external force from tools and mold so as to reduce or eliminate cutting. It includes a variety of techniques, such as forging, rolling, extruding, drawing and punching.

Forging

This is a processing method that uses a kind of forging machine to impose pressure on metallic blank so as to obtain plastic deformation in order to achieve a casting with certain mechanical property, shape and size

According to the forming mechanism, forging can be divided into free forging, die forging, grinding ring, and special forging.

According to the forming mechanism, forging can be divided into free forging, die forging, grinding ring, and special forging.

Mold forging It is formed with a mold on a mold hammer or hot die forging press.

Grinding ring It is referred to the use of special equipment ring rolls to manufacture ring parts with different diameters. Such method can also be used to manufacture auto hub, train wheel hub and other ring parts.

Special forging It includes rolling forging, cross wedge rolling, radial forging, liquid forging and other forging methods, which are suitable for manufacturing some parts with special shapes.

Processing flow

Blank heating -> rolling to prepare blank -> die forging -> cutting the edges -> punching -> rectifying -> intermediate inspection -> heat treatment of forged piece -> clearing -> rectifying -> inspection

Special forging

- The forged piece can bear higher impact as compared with the cast piece. Its plasticity, toughness and other mechanical properties are better than that of a cast piece or even a rolled piece.

- With less materials and processing time.

- Higher productivity.

- Free forging is more flexible and suitable for small lot production of single pieces.

Application Rolls and herringbone gears of heavy mills; rotors, blades and retaining rings of steam turbine generator unit; working cylinder and column of large hydraulic press; locomotive axle; crankshaft and connecting rod of automobiles or tractors.

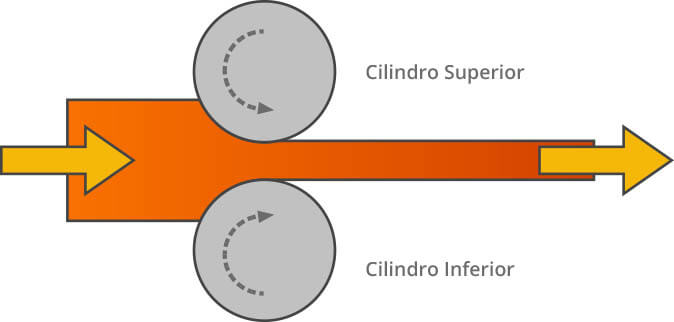

Rolling

A processing method that forces metal blank to pass between a pair of rotary rolls (in various shapes) to reduce material section and increase its length due to compression of the rolls.

Rolling category Axial rolling, cross rolling and skew rolling according to movement of the rolled piece.

Axial rolling: The process in which metal passes and deforms plastically between a pair of rolls that rotate in opposite directions.

Cross rolling: The rolled piece after deformation moves in the same direction with the axis of the rolls.

Skew rolling: The piece under rolling moves helically and it forms a non-special angle with axis of the roll.

Application It is mainly used for metallic section materials, plates or tubes, and some nonmetal products such as plastics and glass.

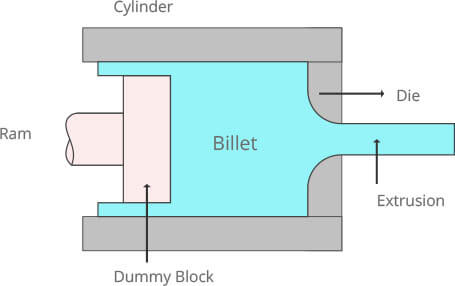

Extruding

A processing method that is used to acquire desired product by extruding the blank, under non-uniform stress in three directions, through a slot or gap so as to reduce its section and increase its length. Such processing of blank is called extruding forming.

Processing flow

Preparation before extruding -> cast rod heating -> extruding -> stretching, twisting and straightening -> sawing (sizing) -> sampling for inspection -> man-hour efficiency -> packing and warehousing piece -> clearing -> rectifying -> inspection

Processing advantages

- Wider scope of production and more product specifications and kinds.

- High flexibility of production is suitable for small lot production.

- High precision in product size and good surface quality.

- Less investment in equipment; reduced workshop floor area; easy to realize automatic production.

Processing disadvantages

- Greater loss of geometrical scraps.

- Non-even metal flow.

- Low extruding speed extends auxiliary time.

- Higher damage to the tools results in higher cost.

Applicable scope of production It is mainly used for manufacturing parts with long stick, deep hole, thin wall or special sections.

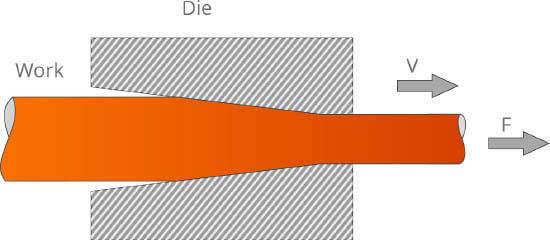

Drawing

A processing method that utilizes the plasticity of metal to acquire products with appropriate shapes and sizes by applying force to one end of the metal and pull the metal blank through a die hole whose section is smaller than that of the metal blank.

Processing advantages

- Precise size and smooth surface.

- Simple tools and equipment.

- Continuously produce long products with small-sections at high speed.

Processing disadvantages

- Limited deformation of pass and limited total deformation between two annealing.

- Length limited.

Applicable scope of production It is a primary method of drawing metal tubes, bars, sectional material and wire rods.

Punching

Punching: A processing method that applies external force to the plate, strip, tube or sectional material with the help of press and mold to achieve plastic deformation or separation in order to obtain desired shape or size of a work-piece (stamping).

Technical features

- Be able to acquire light-weighted, highly rigid products.

- Good productivity makes it suitable for batch product at a lower cost.

- Be able to obtain the products with even quality.

- High utilization of material and good shearing and recovering performance.

Applicable scope of production Of the steels produced in the world, nearly 60-70% are plates, most of which are finished through stamping, including body, chassis, fuel tank and radiator of cars; steam pocket of boiler; container housing; motor; iron core and silicon steel sheet of electric appliances. There are also lots of stamping used in instrument and apparatus, home appliances, bicycles, office equipment, and utensils used in daily life.

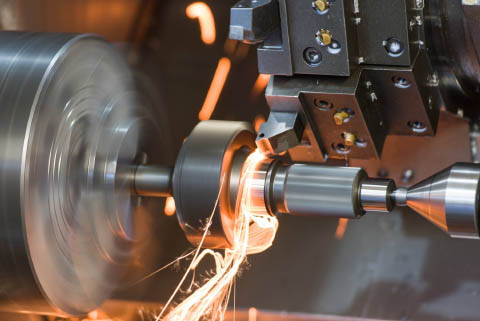

Machining

Machining

Machining is a subtractive manufacturing process in which the part is processed by using a knife to directly cut off extra thickness of metal from the blank in order to achieve the size accuracy, shape and mutual positioning precision, surface quality and other technical requirement of the drawings.

Suppliers of machining equipment Mikron and Bumotec of switsland, DMG and Hermle of Germany, Mori Seiki, Okuma, Mazak and Makino of Japan, MAG and Hardinge Bridgeport of the United States, Italian Fidia, Spanish Danobat, Hardinge and Haas of the United States, Doosan, Hyundai and Samsung of South Korea, Yeongchin, Tong-Tai and Dick Lyons of Taiwan, BYJC, BMEIMT, TONMAC, Shenyang, Shinri, Neway, Rifa, Haitian, Dajin.

Welding

Welding

Welding: Welding is also known as fusion. It is a manufacturing process and technique that splices metal or other plastic materials (such as plastics) with heating, high temperature or high pressure.

Powder Metallurgy

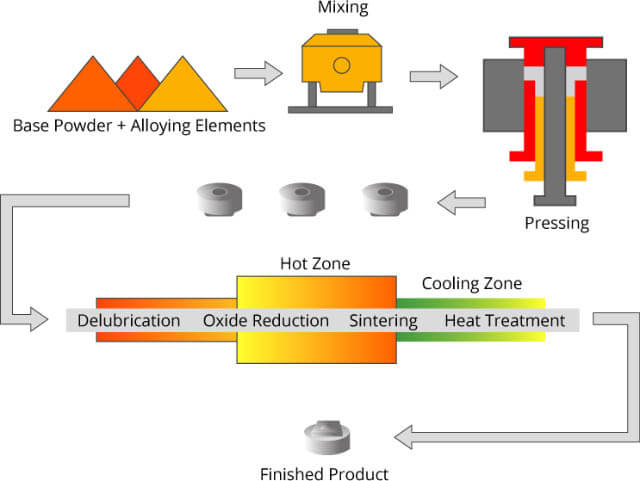

Powder Metallurgy

A processing technique that is used to make metallic materials, composite materials and various products with metal or metal powder (or mixture of metal powder and nonmetal powder) as raw material by forming and sintering. Welding: Welding is also known as fusion. It is a manufacturing process and technique that splices metal or other plastic materials (such as plastics) with heating, high temperature or high pressure.

Basic processing flow

Processing advantages

- Most refractory metals and their compound, fake alloy and porous materials can only be produced with powder metallurgy.

- Metal and product cost can be reduced.

- There is no chance for any contamination to the materials. It is possible to extract highly pure material.

- Powder metallurgy can ensure the correctness and uniformity of material composition proportion.

- Powder metallurgy is suitable for producing a number of products with one but the same shape, which can considerably reduce the cost of production.

Processing disadvantages

- Size of part must be considered when no batch production is required.

- Cost of mold is relatively higher than a casting mold.

Applicable scope of production With powder metallurgy, it is possible to directly manufacture porous, half-dense or full-dense materials and products, such as oily bearing, gear, cam, guide rod and cutting tools.

Forming of semi-solid metals

Forming of semi-solid metals

SSM for short. The unique rheological property and stirring fusibility of SSM can be used to control casting quality.

Semi-solid forming can be divided into Rheoforming and Thixoforming.

1 Rheoforming

Technical features

- With fewer defects caused by liquid forming, the quality and reliability are considerably improved

- With a forming temperature lower than full-liquid forming, heat impact on the mold is considerably reduced.

- This method can manufacture alloys that cannot be made with routine liquid forming method

Application Currently, it has been successfully used for the primary cylinders, steering system parts, rocker arm, engine pistons, wheel hubs, drive system parts, fuel system parts and air conditioner parts in aviation, electronics and consumer goods.