Rapid Prototyping: Everything You Need to Know

The manufacturing world has been revolutionized by the emergence of rapid prototyping, an umbrella term for a range of manufacturing techniques that can fabricate prototypes and parts in a quick and cost-effective manner. This space has grown immensely over the past few decades, and as methods like additive manufacturing, CNC machining, injection molding and vacuum casting become more affordable and accessible, rapid prototyping has become an integral part of product development across all industries.

In the following guide, we’ll cover every aspect of different rapid prototyping techniques and applications, showcasing the different processes, advantages and common applications. Whether you’re looking for the right rapid prototyping method for your own production plans, or simply want to learn more about the various technologies available to you, our Rapid Prototyping Guide has everything to help you make an informed decision on which prototyping path you venture down.

Ready to get started? Let’s jump in.

Table Of Content

Part 1

What is Rapid Prototyping?

Across nearly every industry, rapid prototyping is changing the way that manufacturers are approaching product design and production. The most accurate definition of rapid prototyping can be stated as follows:

Rapid prototyping is comprised of an array of production techniques that are used to take a 3D model and quickly fabricate a scale model of a physical part or assembly.

The most popular form of rapid prototyping is called additive manufacturing (also known as 3D printing). There are a number of 3D printing technologies, each of which is compatible with different materials and offers distinct benefits. Other technologies that are capable of rapid prototyping includes CNC machining, injection molding and vacuum casting.

Why Should You Use Rapid Prototyping?

1. Bringing Design Concepts to Life – First and foremost, one of the biggest advantages of rapid prototyping is that it allows you to realize design concepts in the physical world. When developing a product or part for mass production, the ability to create physical prototypes is a crucial part of the process. Rapid prototyping provides an affordable and quick way to iterate your design for mechanical testing and to ensure the dimensions match the designer’s intentions.

2. Reducing Production Costs and Time – Rapid prototyping can also greatly reduce overall production costs. For example, additive manufacturing technology eliminates the need for moulds, patterns and special tools, which are oftentimes quite costly. Additionally, using rapid prototyping techniques will allow you to optimize and repair any potential flaws in your design before it’s sent off for mass production.

In the manufacturing world, time equals money, so you’ll be pleased to hear that rapid prototyping also reduces the time needed for the product development process. With rapid prototyping, you can quickly iterate your design and ensure that it’s ready for mass production in a time-efficient manner.

3. Make Changes Quickly – Not only does rapid prototyping help bring your design concepts to life (as we mentioned earlier), it also enables designers and engineers to make quick changes to their product or part on a whim. Let’s say you create a prototype of a part. Once you have it in your hands, you suddenly realize that there’s something you can repair or optimize to reduce mass production costs or improve the user’s experience. With rapid prototyping technologies like 3D printing or CNC machining, you can modify or repair a design and have it iterated in the nick of time. Instead of realizing where the mistakes are during the mass production process, which can setback production time and costs, rapid prototyping makes it easy to make changes to your design without having to invest too much money or time.

4. Customization – Rapid prototyping also makes it possible to develop highly customizable parts and products that meet individual requirements. Since no tooling or process is needed with these manufacturing techniques, it’s easy and relatively cheap to personalize and reiterate your model.

When using traditional manufacturing techniques, even minor changes in a design will alter the entire production process. But with rapid prototyping methods like 3D printing or CNC machining, these changes can be implemented without impacting the overall manufacturing process. This is a major benefit for both companies and consumers, as parts can be given a highly personalized touch.

5. Reduce Design Flaws – With rapid prototyping processes like additive manufacturing, you are able to physically produce a part or product and ensure that there are no design flaws. By using plastic or metal material that resembles the one that will be used to produce the final product, you can conduct physical tests to see if the properties and part strength meet your requirements. This allows companies and manufacturers to discover flaws or functionality issues in the early stages of product development stage, saving an immeasurable amount of time and money.

Types of Prototypes

There are a number of terms used to characterize various types of prototypes. With rapid prototyping in particular, you’ll find that there are numerous styles to choose from, each tailored to meet different production demands. Here is a brief overview of the terms that encompass the world of rapid prototyping.

1. Looks-like Prototype – A “looks-like prototype” is a primarily aesthetic part. This kind of prototype is focused on replicating the outer appearance and usability of the product, valuing the visual aspect over the functional. A looks-like prototype can be used to create a perception or provide a first impression of your product to customers, impacting the buying decision and how the end-product will be received on the market. Although this style of prototype can be created out of nearly any material, FDM 3D printing technology has become an increasingly popular technique due to its ability to create complex geometries at an affordable price

2. Works-like Prototype – A “works-like prototype”–better known as a functional prototype– is meant to showcase to core functionality and mechanical abilities of your part or product. Aside from the physical object itself, it’s also common to utilize development boards and other electronic components to demonstrate how the prototype will work in its final form.

This type of prototype doesn’t necessarily have to show off the visual quality of your product, and can sometimes look like wire spaghetti or a makeshift object. But that’s okay. The main purpose here is to test the functionality of your design. And so, when you’re designing for a works-like prototype, the material you choose is just as important as the manufacturing process. It’s important to select a material that resembles the mechanical properties of the one that will be used in mass production. Therefore, injection molding, CNC machining, vacuum casting or industrial-grade 3D printing will likely be used in these cases.

3. Hybrid Prototype – A hybrid prototype is one that combines the visual aspect and mechanical aspects into one product. This type of prototyping is useful when refining the aesthetics and form of your product, while also testing the functionality and placement of electronics. Using rapid prototyping techniques like CNC machining or 3D printing, you can create a hybrid prototype that replicates both the aesthetic and mechanical value of your product.

4. Pre-production Prototype – Last but not least is the pre-production prototype, which you can probably guess is a prototype that is close to replicating the end-product. This type of prototype is usually produced with a manufacturing process that is either the same or similar to the one that will be used in mass production. This is when CNC machining and injection molding becomes the go-to rapid prototyping technique. The purpose of pre-production prototypes is to identify and solve any potential problems before entering the final production phase. With this type of prototype, you can check all specifications and apply for necessary certifications. Since this is the final step before mass production, most engineers and manufacturers use this opportunity to ensure the design is optimized for manufacturing. In order to guarantee a successful production workflow, you should take a number of factors into consideration, including manufacturing, pricing, usability, transportation, user experience, sustainability and more.

Part 2

In the following sections, we’ll show you the most popular rapid prototyping technique, how to get a prototype made, how to find a rapid prototyping service and how to request a quote from the service provider. Let’s get started!

Additive Manufacturing (3D Printing Technology)

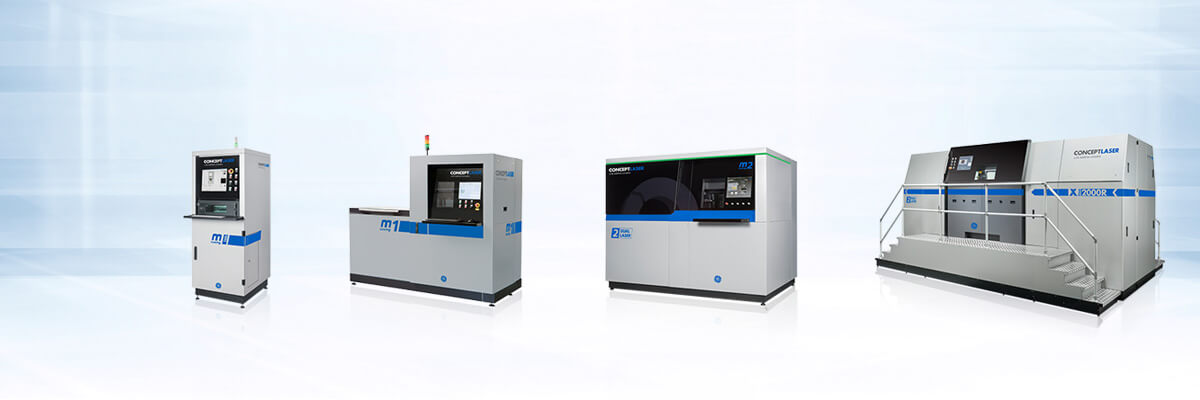

Widely recognized as the most popular rapid prototyping techniques, additive manufacturing (more commonly referred to as 3D printing) has made tremendous strides over the past decade. The technology has advanced in numerous ways, and is now more affordable and accessible than ever before.

There’s a distinct range of 3D printing processes that are utilized for rapid prototyping applications, one differing slightly from the other. Therefore, it’s important to understand the most commonly used forms of 3D printing and what they have to offer.

1. Fused Deposition Modeling (FDM) – The most popular form of 3D printing is Fused Deposition Modeling (FDM), which works by depositing melted thermoplastic strands through a heated nozzle, building up an object layer-by-layer. This process has a presence on both the industrial and consumer market. While aesthetically-driven prototypes can be iterated on a cheap desktop FDM 3D printer, industrial machines offer improved mechanical properties, larger print capabilities and higher print resolution.

If you need to produce functional plastic prototypes as quickly as possible, FDM 3D printing is a tremendously affordable and viable option. This particular rapid prototyping process is compatible with an array of thermoplastic materials that are used in traditional manufacturing, such as ABS, Nylon, PLA, TPU/TPE, PET, PC, PEEK and others.

FDM 3D printing is one of the most cost-effective ways to produce custom parts or prototypes from thermoplastic materials. When using a rapid prototyping service, this process generally provides an extremely short lead time of just a few days. And, since the CAD model is built-up one layer at a time, there’s nearly zero material waste.

The benefits of FDM 3D printing are quite apparent, but there are also some limitations that you might not be aware of. For starters, FDM provides low dimensional accuracy and poor surface resolution compared to other 3D printing processes. So, if you have a part that has intricate or complex details, you might want to search for another option. The layering process also causes a few problems. That’s because FDM parts have visible layering lines that require post-processing. The layer-by-layer process also makes parts inherently anisotropic, meaning greatly reduced a part’s strength in certain directions.

Therefore, FDM 3D printing is a good rapid prototyping technique to use when you need to produce a prototype quickly and at an affordable price. If you have a functional prototype or a part with intricate details, there’s likely a more suitable process out there.

2. Stereolithography (SLA) – Another increasingly popular form of 3D printing technology is stereolithography (SLA). It uses a high-powered laser to solidify a 3D model– also in a layer-by-layer process –from a vat of resin. SLA 3D printers are known to produce high resolution prints at a fast rate, making it increasingly popular for visual models and prototypes, and for medical and dental models as well.

There is a wide range of application-focused resin materials on the market, each engineered to meet the standards of different part requirements.

The benefits of SLA 3D printing are plentiful, especially when you need a highly realistic prototype or model. It offers high precision and exceptional resolution, producing incredibly thin layers with a fine laser beam. It’s also easier to produce complex and intricate prototypes compared with most other rapid prototyping techniques.

Surface quality is the main selling point of using SLA 3D printing. Parts printed with this technique typically have a smooth finish and great layer resolution. With SLA, designers can prototype and produce extremely small parts or larger parts with professional-grade precision.

Other benefits of using SLA 3D printing through a rapid prototyping service include low lead times and cost.

But there are also downsides to SLA when it comes to rapid prototyping applications, especially those that require mechanical testing or large-volume runs. Although prototypes produced with this method sport an incredible surface quality, they also tend to be fragile, rendering them unfit for mechanical testing. Compared to other rapid prototyping techniques, SLA 3D printing is relatively slow due to post processing and build volume limitations, so feasibly producing a high number of prototypes is out of the question.

4. Selective Laser Sintering (SLS)/Direct Metal Laser Sintering (DMLS) – Selective laser sintering (SLS) is a rapid prototyping technique that utilizes a high powered laser to sinter powdered material into a part or prototype. An SLS machine is equipped with a pulse laser that selectively fuses powdered material by scanning cross-sections generated from a CAD model. Using a lowering bed that is packed with powder, a new layer of material is applied after the previous layer has been fabricated.

While SLS 3D printing is used to produce plastic prototypes, the term used for metal production is direct metal laser sintering (DMLS). Considered a subset of SLS, DMLS also uses a high power-density laser, but to melt and fuse metallic powders together instead of plastics.

There are also some disadvantages to SLS, the biggest of which is that the surface is sometimes porous and rough. Plastic parts printed with SLS also face issues with thermal distortion, which can cause shrinking and warping in the part. However, these are problems that can be overcome by using a professional rapid prototyping service.

3D Printing _Rapid Prototyping Techniques

Before we move on, here’s a brief recap on the advantages of the aforementioned 3D printing processes.

If you have heavy time and cost restraints, and can settle for a physical prototype that lacks a high resolution surface quality and certain mechanical properties, FDM 3D printing is probably the best option for you.

If the visual component of your prototype is important to you, and you don’t mind having a more fragile part on your hands, then SLA 3D printing is superior to FDM.

Lastly, if you need to 3D print a plastic or metal prototype that has a pristine surface quality and adequate mechanical properties, SLS or DMLS is the way to go.

Although 3D printing is considered by many to be the star celebrity of rapid prototyping, there are other processes that you can use to your advantage. Depending on the part design and application, you might find more value in CNC machining, injection molding or vacuum casting. Let’s take a look at how these three manufacturing methods work and the advantages they present in rapid prototyping applications.

CNC Prototype Machining _Rapid Prototyping Techniques

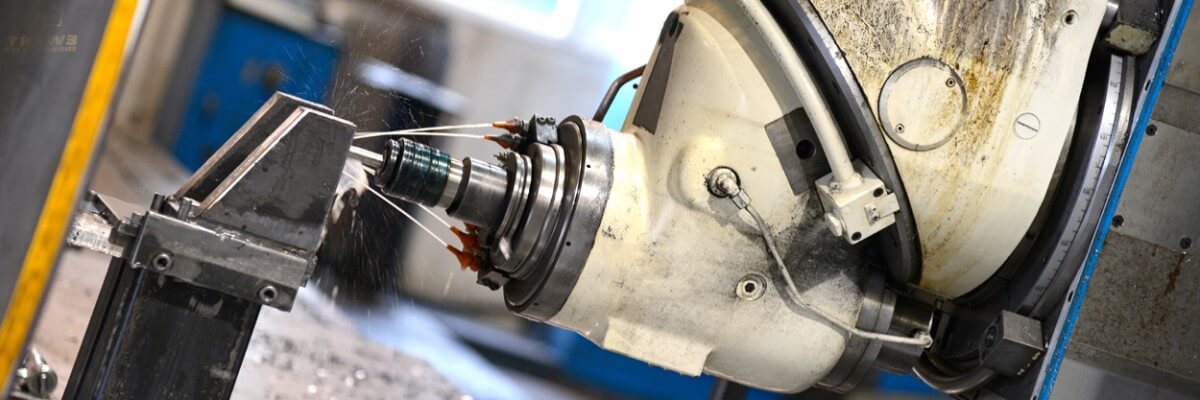

As we mentioned, rapid prototyping isn’t only confined to 3D printing. In fact, CNC machining can be even more advantageous depending on the application and requirements of the part. Unlike 3D printing, which is an additive technology, CNC prototype machining is a subtractive manufacturing technique, meaning that it uses cutting tools to cut away at a solid block of plastic or metal material to produce a prototype or part.

This process utilizes digital instructions from a CAD or CAM file to cut the desired part using various cutting and drilling tools. For more complex prototypes that require different kinds of cuts, multiple tools can be automatically swapped onto the machining head.

Most professional rapid prototyping service providers have 3-,4-, and 5-axis CNC machines. 3-axis machines are able to move laterally on the x, y and z-axis, while the more advanced 5-axis machine is capable of flipping a part over and machining both sides of a material. In some cases, both additive manufacturing and CNC machining can be used in tandem to produce prototypes.

The primary advantage of CNC machining is that there are very few material limitations. This rapid prototyping technique is compatible with a vast range of engineering-grade plastics and metals, including aluminum, brass, copper, steel, and titanium. You can also use materials like wood, foam, and fiberglass

There are some disadvantages to CNC machining as well. These machines are typically quite costly to operate, and require a skilled operator to ensure that the process goes smoothly. Again, by using a rapid prototyping service, you can easily overcome these obstacles. There are also certain design limitations, as the part can only be as big as the material substrate. In addition, CNC machining is unable to achieve certain complexities that techniques like additive manufacturing can.

All in all, CNC machining is a superb rapid prototyping technique to use when you need a small-to-medium runs of parts that are both consistent and highly accurate. It’s especially useful for prototyping functional parts in metal or clear PMMA, providing high repeatability and advanced mechanical properties.

Injection Molding _Rapid Prototyping Techniques

Although some consider it to be a more traditional manufacturing technique compared to 3D printing, injection molding and rapid tooling can also be used for certain rapid prototyping applications. It’s ideal for large-scale production due to its high repeatability and fast turnaround. The injection molding process starts with the design of a mold or die, which is split into two halves. Once the mold is produced, typically out of hardened steel or aluminum via CNC machining, it’s prepared for injection molding.

Now comes the fun part… First, a thermoset (epoxy resin) or thermoplastic material in granular form and is fed into a heating barrel. Once the desired temperature is reached, the molten material is injected with force into the mold, where extremely high pressure is applied to solidify the part before the cooling process begins. Once the cooling process is completed, the mold is opened and the part is ejected. This process can be repeated thousands of times, making it the go-to option for large-volume production.

One advantage of injection molding is that you can produce prototypes with detailed features and complex geometries. The high pressure that is applied during the injection molding process makes it possible to add intricate details into the design. It can also produce complex and intricate shapes that would be considered impossible with other traditional manufacturing techniques.

It takes some time to design and produce a viable mold for injection molding, but the molding process is extremely fast and efficient, enabling you to rapidly prototype a large-volume of parts in a short time span. Therefore, injection molding can also be very cost effective.

Another benefit that makes injection molding appealing for rapid prototyping is the enhanced strength that can be added to parts. For instance, a filler material can be used in molds to reduce part density and increase strength after it has been molded. Compared to 3D printing, the strength of injection molded parts is far superior. It’s also possible to use a mixture of materials in one part, which can be leveraged to add strength, reduce weight, and achieve other mechanical properties. And, to top it off, injection molding has very little material waste, as every bit of material is used or can be reused during the process.

If your rapid prototyping application requires a functional prototype that can be tested or a large-volume production, injection molding might be the best choice for you. One of the downsides is the complexity of designing an errorproof mold, which requires a lot of design considerations. Thankfully, you can use a rapid prototyping service to help design and optimize your mold before it goes into production.

Vacuum Casting _Rapid Prototyping Techniques

Vacuum casting is another fast and cost-efficient rapid prototyping technique, and like injection molding involves the use of a mold. The process starts by placing a two-piece silicone mold into a vacuum chamber. Then, a raw material is mixed and poured into the mold, where the part is solidified inside of the vacuum chamber. The casting is then cured inside of an oven and the mold is released revealing a completed part.

Vacuum casting molds can be reused a handful of times (around 20 or more), making it ideal for low-volume prototyping purposes. Parts produced with vacuum casting can have a high degree of flexibility and rigidity, and can be made in variety of colors and resin materials, such as ABS, POM, Elastomers, Nylon, and more.

Vacuum casting creates parts with exceptional mechanical properties, which is ideal for functional prototyping. It’s also capable of creating parts with high accuracy and visual details, patterns, dimensions, profiles, and textures. This makes vacuum casting valuable in creating colorful products and marketing material

Despite the versatility and speed of this process, there are some downsides to vacuum casting as well. For instance, the price per vacuum forming mold makes it more expensive than injection molding for large-volume productions. Similarly, post-processing and finishing costs can sometimes be costly and increase production time. There are also certain intricacies that vacuum casting is unable to successfully reproduce as well as 3D printing or CNC machining.